bobbiemartin

Author of The DB2 Conversion Guide

A quick update. The cam bearings are in although it took two sets and I'm still not 100% happy, but its probably as good as its going to get. I have all the internals back, the balancing at least looks nice. It took two plugs of Mallory metal to balance the crank. I hope the balancing will make engine run smoother.

Found a problem last night with the rings. I was checking the ring end gaps and found one set was way too big, the rings actually overlap in the bore. All the rest are in spec, so not sure what is going on. Must have somehow supplied the wrong set at the factory. I'm waiting to hear from Kennedy what Mahle will do. I could file them, but they are way too big and that is a lot of filing. If Mahle doesn't come through, I can get a single ring set on eBay, but I hope I don't have to pay for them out of my pocket.

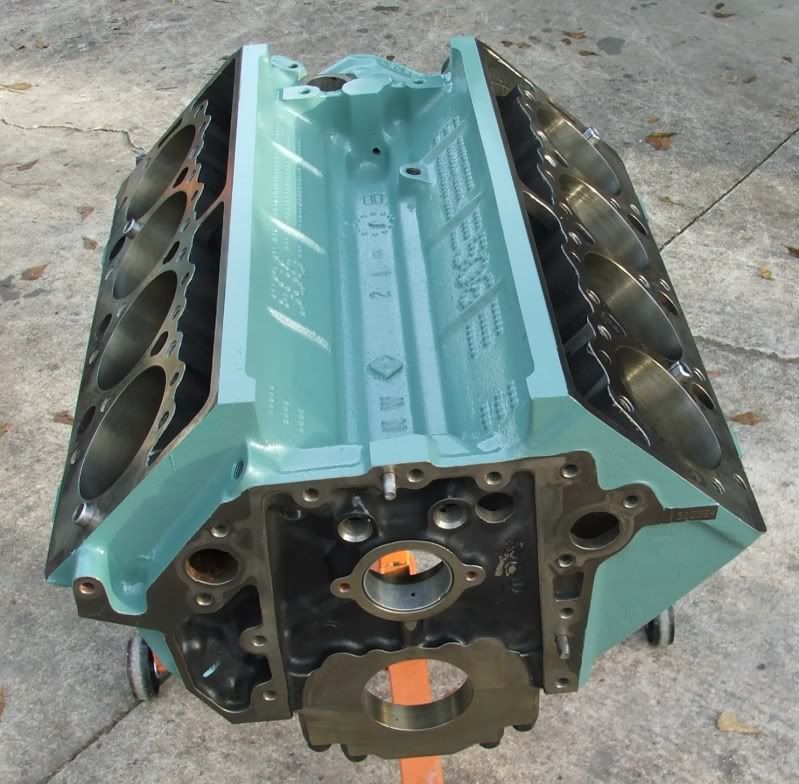

I'm still waiting on the bearings and such from Peninsular. Got a call from them, for some reason UPS returned the shipment back to them, so I hope to have it this week. I should get the block and heads painted this weekend. Hope to start the build soon, but the rings may hold that up a few days. Its always something!

Found a problem last night with the rings. I was checking the ring end gaps and found one set was way too big, the rings actually overlap in the bore. All the rest are in spec, so not sure what is going on. Must have somehow supplied the wrong set at the factory. I'm waiting to hear from Kennedy what Mahle will do. I could file them, but they are way too big and that is a lot of filing. If Mahle doesn't come through, I can get a single ring set on eBay, but I hope I don't have to pay for them out of my pocket.

I'm still waiting on the bearings and such from Peninsular. Got a call from them, for some reason UPS returned the shipment back to them, so I hope to have it this week. I should get the block and heads painted this weekend. Hope to start the build soon, but the rings may hold that up a few days. Its always something!