bobbiemartin

Author of The DB2 Conversion Guide

Spent some time today cleaning up the block and smoothing out the rough cast edges. I'll be taking the block out to the machine shop in the morning.

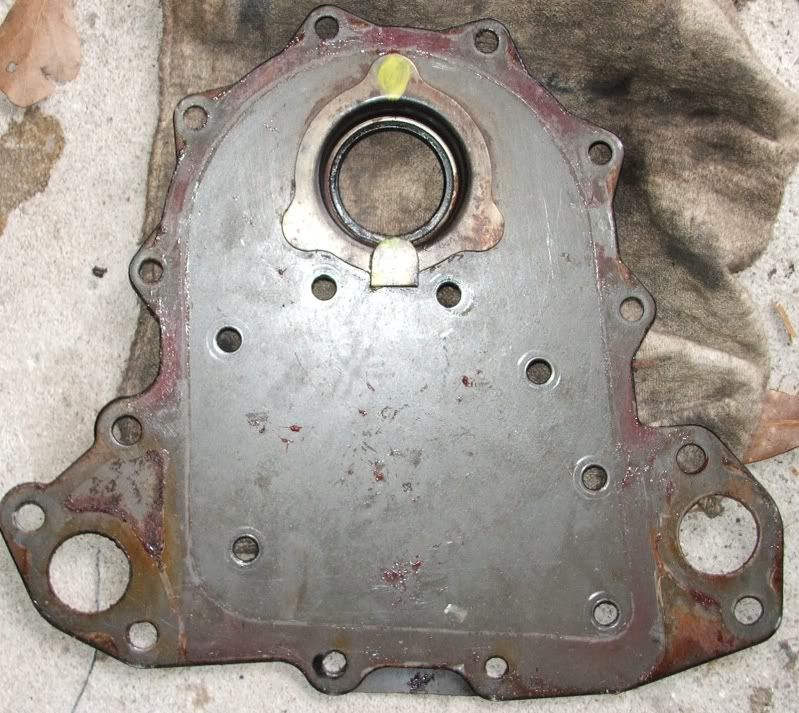

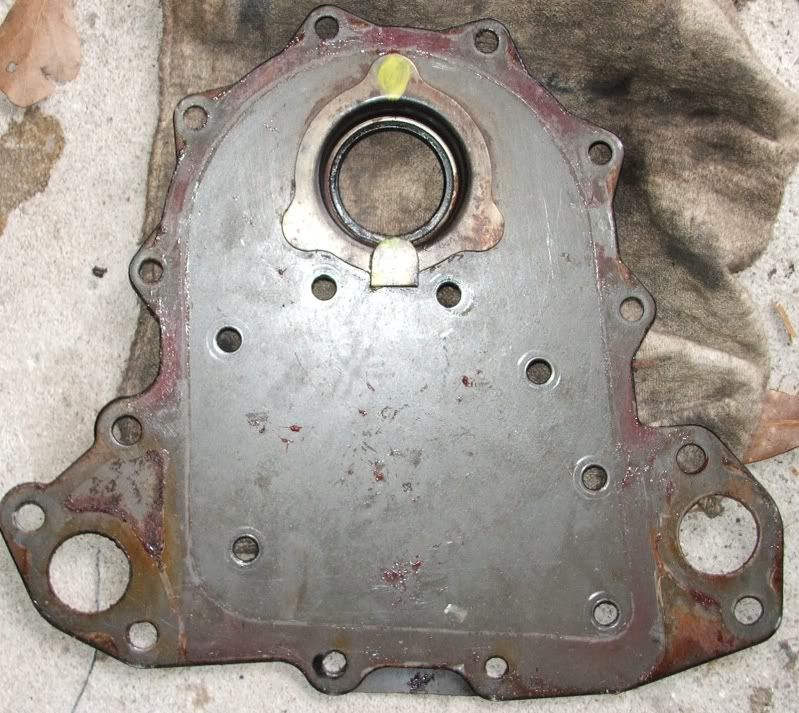

Here is the water pump backing plate. Its like new.

Even though this is an oil squirter block, the oil pump does not have a sandwich plate. Anyone know if the changed the design to a deeper one piece pump?

I'm not sure if this pickup will fit a truck oil pan. I bought a new oil pan off eBay for a good price, should be here this week. Once the block gets back, I'll see how the pump fits.

Here is the water pump backing plate. Its like new.

Even though this is an oil squirter block, the oil pump does not have a sandwich plate. Anyone know if the changed the design to a deeper one piece pump?

I'm not sure if this pickup will fit a truck oil pan. I bought a new oil pan off eBay for a good price, should be here this week. Once the block gets back, I'll see how the pump fits.