Here we go again, this was a new DB2833-4974 made for Peninsular Diesel with .350 plungers that I drove for 400-500 miles, then I put the pump on a pretty highly modified P400 and it was not enough fuel so I sent it to Conastoga. When I got it back and installed it and it seized the .350 head & rotor at idle before it ever got put in gear. I then sent it back and paid for a NEW .330 head and rotor. I installed it and it won't run for shit at idle and I can't advance it enough to run right before I install the intake manifold & turbo. I installed a zero hour run time rebuilt .310 pump I have on the engine and it runs like I would expect it to.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome to The Truck Stop! We see you haven't REGISTERED yet.

Your truck knowledge is missing!

- Registration is FREE , all we need is your birthday and email. (We don't share ANY data with ANYONE)

- We have tons of knowledge here for your diesel truck!

- Post your own topics and reply to existing threads to help others out!

- NO ADS! The site is fully functional and ad free!

Problems registering? Click here to contact us!

Already registered, but need a PASSWORD RESET? CLICK HERE TO RESET YOUR PASSWORD!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

P400 in the Burb install

- Thread starter spdgofast

- Start date

Rockabillyrat

SlIgHtLy StUpId.

Ok, your post from a few days ago you stated it was the second pump they built for you. So I assumed it was a different pump. That pump has been rebuilt twice now then by them.

Did peninsular do pumps in house? I never got the chance to deal with them before they closed. I know stanadyne lists their .330 and .310 4 plunger pumps in the older price catalog. But never a .350, so it might be a custom built pump from the start. If so, it may have been apart quite a few times. There could be a advance piston bore issue.

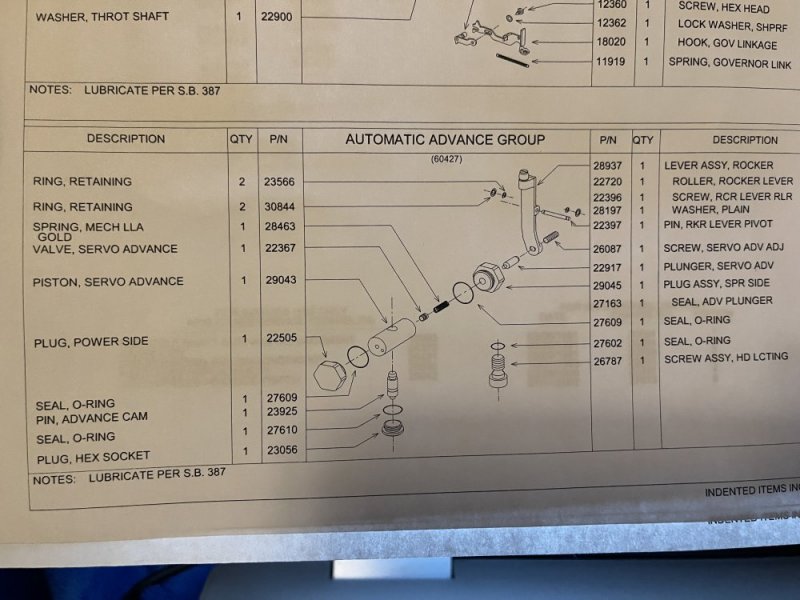

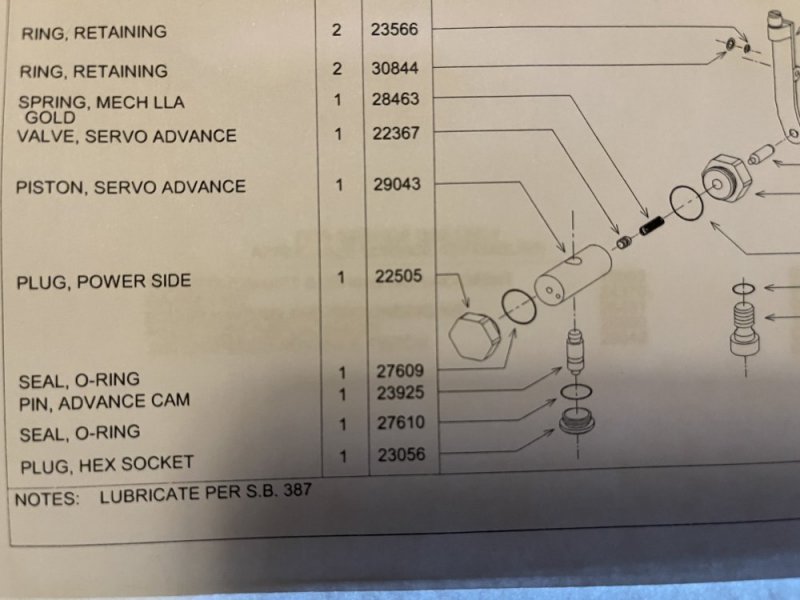

The advance servo could also be stuck, I forgot to mention that.

Did peninsular do pumps in house? I never got the chance to deal with them before they closed. I know stanadyne lists their .330 and .310 4 plunger pumps in the older price catalog. But never a .350, so it might be a custom built pump from the start. If so, it may have been apart quite a few times. There could be a advance piston bore issue.

The advance servo could also be stuck, I forgot to mention that.

n8in8or

I never met a project I didn’t like

It really sucks Conestoga isn’t what they used to be since they lost Joel.

Will L.

Well-Known Member

Question would be, is he working at a different shop?It really sucks Conestoga isn’t what they used to be since they lost Joel.

n8in8or

I never met a project I didn’t like

He isn’t. He got a job as a shop manager in a different profession unfortunately (unfortunately for us….he’s much happier doing what he’s doing now). Joel won’t be making any more pumps.Question would be, is he working at a different shop?

We just need Rockabilly to get his pump operation from Death Star status to fully operational. (Sorry, the influence of May the 4th is still strong with this one). Rockabilly’s pumps should blow Conestoga’s out of the water in both output and quality.

The pump was modified from a new pump at Diesel Injection Service in Grand Rapids Mi, which as for as I know is who did all of Peninsulars work, I spoke to the guy that built the pump several times. Mel @ Conastoga was the first person to touch the pump and like I said it seized the head & rotor at idle on my truck. I then sent it to him and he put a new .330 head & rotor and did whatever he does and It's never ran good enough to put the truck in gear. I put my stock .310 pump on that I bought for a test/spare and it runs good but I'm sure it's not enough fuel for my engine if the .350 plunger pump wasn't enough. So obviously I'd be better of if I never sent it to Conastoga.Ok, your post from a few days ago you stated it was the second pump they built for you. So I assumed it was a different pump. That pump has been rebuilt twice now then by them.

Did peninsular do pumps in house? I never got the chance to deal with them before they closed. I know stanadyne lists their .330 and .310 4 plunger pumps in the older price catalog. But never a .350, so it might be a custom built pump from the start. If so, it may have been apart quite a few times. There could be a advance piston bore issue.

The advance servo could also be stuck, I forgot to mention that.

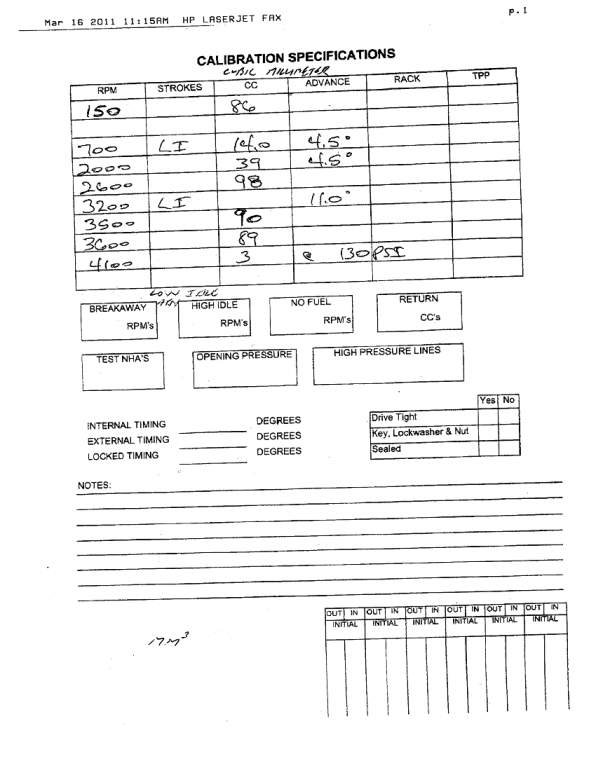

This was supposed to read like this....Here are the pump tags, the first one is the .350 plunger pump, not the DB2835-PE340 on the first one? That's for Peninsuler 340 HP.

The second one is the POS .330 plunger Omega Moose pump.

Here are the pump tags, the first one is the .350 plunger pump, note the DB2835-PE340 on the first one? That's for Peninsuler 340 HP.

The second one is the POS .330 plunger Omega Moose pump.

Attachments

Will L.

Well-Known Member

That would be hard...not involving bail money, lets say. Here in the desert, there are a lot of covered over holes.

I don’t do social media of any sort other than this site and the hummer one. But if anyone is good at sharing info this story should blow up the web and be in front of every potential customer they have.

It’s like taking an award winning condition Duesenberg in for a transmission repair and them driving over it with a tank.

I don’t do social media of any sort other than this site and the hummer one. But if anyone is good at sharing info this story should blow up the web and be in front of every potential customer they have.

It’s like taking an award winning condition Duesenberg in for a transmission repair and them driving over it with a tank.

"Social Media" LOL....

I have seen that in today's world where folks don't take the time to do there own research on any question they may have, they just post on FB or other places and other "kids" will chime in with there year or two of experience, that is no more than something another youngster said, and that will be fact, I laugh about some of the things I see on FB pages with these motors, I don't bother to give my thoughts I just let the bad info keep flowing, some need to learn by spending money on BS.....

Sorry, but yes I'm a old fart, and I'm well past trying to set some records straight....

I have seen that in today's world where folks don't take the time to do there own research on any question they may have, they just post on FB or other places and other "kids" will chime in with there year or two of experience, that is no more than something another youngster said, and that will be fact, I laugh about some of the things I see on FB pages with these motors, I don't bother to give my thoughts I just let the bad info keep flowing, some need to learn by spending money on BS.....

Sorry, but yes I'm a old fart, and I'm well past trying to set some records straight....

Rockabillyrat

SlIgHtLy StUpId.

Plunger size isn't all that matters on a DB2. A .310 can be modified to out flow a turned up .330 or even .350 with out a problem. There are few parts that can be swapped internally to increase the roller to roller spec. As well as messing with the minimum throttle calibration.

Peninsular saying that .350 pump was rated for 340hp has me to believe it was using stock internals other than the .350 plungers. I say that because 380-400hp is doable on a highly modified .310 pump.

So that brings up something I didn't think about. If conestoga swapped internal parts to try and increase roller to roller spec for more fuel. It may be that the force from the rollers hitting lower in the cam ring is over powering the advance piston. The DB2 cam ring was never designed to have the rollers ride against it 100% of the time like a DS4. The leafspring restricts the travel of the shoe so the roller only hits the middle part of the cam ring lobes. The lobes are not very smooth almost like a 3 hump design. If you increase the roller to roller spec it hits on the first hump, the force to push past that might be screwing up the timing advance.

A veteran pump builder who I really respect warned me of this issue on modified pumps. Putting it back on a test stand with the timing gauge would tell you if thats the case.

Only thing holding me back from offering pump builds is my test stand. I've dropped some serious money in all the tooling. My clean room is set up and ready to build. But without being able to calibrate them I can't offer them yet. The plan is this summer to be fully operational and become a vendor here.

Peninsular saying that .350 pump was rated for 340hp has me to believe it was using stock internals other than the .350 plungers. I say that because 380-400hp is doable on a highly modified .310 pump.

So that brings up something I didn't think about. If conestoga swapped internal parts to try and increase roller to roller spec for more fuel. It may be that the force from the rollers hitting lower in the cam ring is over powering the advance piston. The DB2 cam ring was never designed to have the rollers ride against it 100% of the time like a DS4. The leafspring restricts the travel of the shoe so the roller only hits the middle part of the cam ring lobes. The lobes are not very smooth almost like a 3 hump design. If you increase the roller to roller spec it hits on the first hump, the force to push past that might be screwing up the timing advance.

A veteran pump builder who I really respect warned me of this issue on modified pumps. Putting it back on a test stand with the timing gauge would tell you if thats the case.

Only thing holding me back from offering pump builds is my test stand. I've dropped some serious money in all the tooling. My clean room is set up and ready to build. But without being able to calibrate them I can't offer them yet. The plan is this summer to be fully operational and become a vendor here.

Rockabillyrat

SlIgHtLy StUpId.

Everything looks good in the video

That housing has had the advance piston bore sleeved. I know stanadyne started doing that from the factory at some point. But I don't know what year they switched over. Only thing you can't tell is if the advance servo is stuck. But I'm starting to think this is a issue with the roller to roller spec being increased causing your timing issues.

Only 98cc from that .350! A .310 with proper modifications can flow 150ish. Id say that was a stock pump with .350 plungers then.

That housing has had the advance piston bore sleeved. I know stanadyne started doing that from the factory at some point. But I don't know what year they switched over. Only thing you can't tell is if the advance servo is stuck. But I'm starting to think this is a issue with the roller to roller spec being increased causing your timing issues.

Only 98cc from that .350! A .310 with proper modifications can flow 150ish. Id say that was a stock pump with .350 plungers then.

Do I take the bottom plug out to check the advance servo?Everything looks good in the video

That housing has had the advance piston bore sleeved. I know stanadyne started doing that from the factory at some point. But I don't know what year they switched over. Only thing you can't tell is if the advance servo is stuck. But I'm starting to think this is a issue with the roller to roller spec being increased causing your timing issues.

Only 98cc from that .350! A .310 with proper modifications can flow 150ish. Id say that was a stock pump with .350 plungers then.

Regarding the fuel rate of the .350 pump, this is why I've been chasing more fuel output.

Another thing I'm trying to understand is when you tighten the screw on the leaf spring lets say a 1/4 turn how does that increase fuel output? Is that the screw that you turn? I'm not intending to do it on this pump I'm just trying to learn about the workings of these pumps. I am thinking of turning up the .310 pump I have on the engine now if I can't find anyone to build me another pump. It's really my only option at this point. FYI I had my local pump shop give me the STANADYNE injection specification pages and diagram for a DB2833-4974 pump yesterday so I have it on hand for reference. I really appreciate your time Rockabilly!

Rockabillyrat

SlIgHtLy StUpId.

Do I take the bottom plug out to check the advance servo?

Regarding the fuel rate of the .350 pump, this is why I've been chasing more fuel output.

You have to pull the LLA armature off. That will allow the plunger to slides out. Then remove the end plug and the spring and servo should slide out of the end of the advance piston.

Another thing I'm trying to understand is when you tighten the screw on the leaf spring lets say a 1/4 turn how does that increase fuel output? Is that the screw that you turn? I'm not intending to do it on this pump I'm just trying to learn about the workings of these pumps. I am thinking of turning up the .310 pump I have on the engine now if I can't find anyone to build me another pump. It's really my only option at this point. FYI I had my local pump shop give me the STANADYNE injection specification pages and diagram for a DB2833-4974 pump yesterday so I have it on hand for reference. I really appreciate your time Rockabilly!

There is a leaf spring inside the pump. When you turn the screw it pushes the center of the leaf down and the ends of it extend out. The leafspring is what limits the shoe movement thus limiting plunger travel. The more you tighten it down the more the room the plungers have to move. So more fuel!!

I have all the calibration sheets, parts diagrams, and service bulletins for ALL the GM pumps. Im ready once the stand it up and running

So if I get that apart the servo advance valve should just fall out if I turn the pump on its side if it's not stuck correct? Or do I need to take a magnet or something to get it out? see diagram

Attachments

Rockabillyrat

SlIgHtLy StUpId.

Yep, it should come right out.