Rockabillyrat

SlIgHtLy StUpId.

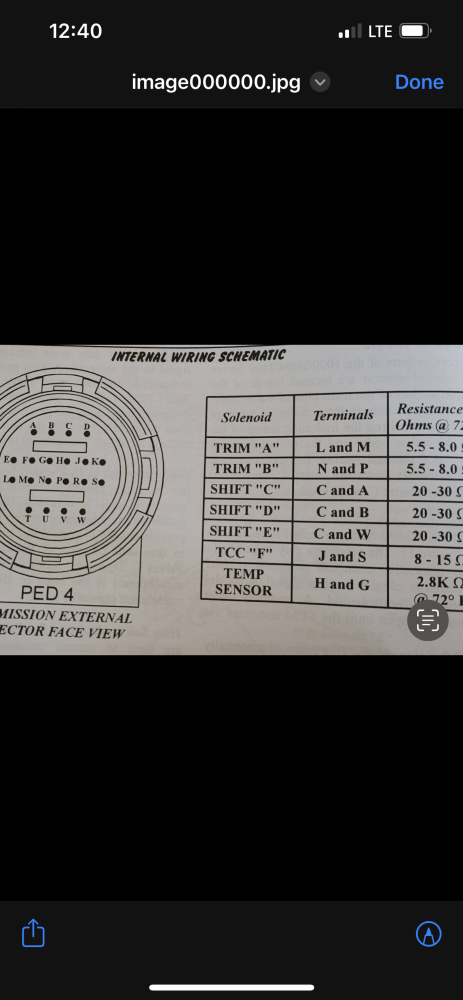

If the solenoid code returns immediately and it ohms slightly out of spec (5.5 ohms), my money is on that its bad.

If I had this at the shop I would pull the pan and test the wiring from the TCM to the solenoid just to eliminate any connection issues at the transmission or the internal harness as the cause of the problem. I would bulb check it, then ohm the each wire from end to end and see if there is enough resistance to make it read out of spec. If that's good then put a new PCS in it and retest it.

If I had this at the shop I would pull the pan and test the wiring from the TCM to the solenoid just to eliminate any connection issues at the transmission or the internal harness as the cause of the problem. I would bulb check it, then ohm the each wire from end to end and see if there is enough resistance to make it read out of spec. If that's good then put a new PCS in it and retest it.