CBR consulting

Well-Known Member

- Messages

- 117

- Reaction score

- 337

2005 gmc c5500.

allison 1000

Story about this truck. I purchased it with the assumption it needed a trans. Since then I have realized with the help of DHD. (Dirty hooker diesel) that someone had made a mess of the valve body.

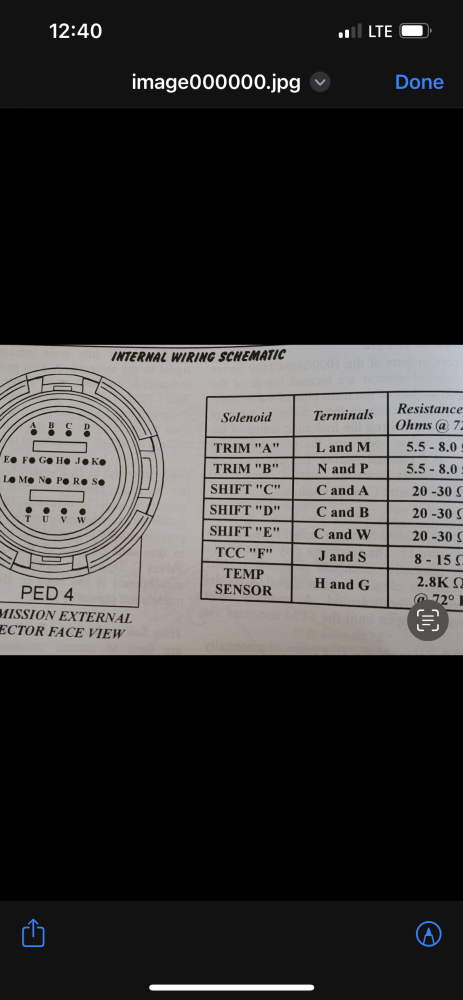

Valve body was gone through with DHD in Michigan. New solenoids, new internal harness, new pressure switch.

new NSBU

New ignition switch

I have installed the the valve body.

I have no reverse or drive still. If you unplug the trans side of the harness, reverse and drive come back.

I have ohms each wire going from the TCM red connector to the trans side of the 20 way plug. Each wire reads 0.08. Which I’m assume is correct for the harness.

I pulled the complete harness back and didn’t see any bad wires other than an open wire on the turbine sensor. Which I have repaired.

I borrowed a TCM from a running truck and no changes.

I’m currently getting codes po713 and p0748.

Does anybody have some help on this

allison 1000

Story about this truck. I purchased it with the assumption it needed a trans. Since then I have realized with the help of DHD. (Dirty hooker diesel) that someone had made a mess of the valve body.

Valve body was gone through with DHD in Michigan. New solenoids, new internal harness, new pressure switch.

new NSBU

New ignition switch

I have installed the the valve body.

I have no reverse or drive still. If you unplug the trans side of the harness, reverse and drive come back.

I have ohms each wire going from the TCM red connector to the trans side of the 20 way plug. Each wire reads 0.08. Which I’m assume is correct for the harness.

I pulled the complete harness back and didn’t see any bad wires other than an open wire on the turbine sensor. Which I have repaired.

I borrowed a TCM from a running truck and no changes.

I’m currently getting codes po713 and p0748.

Does anybody have some help on this