Big T

Well-Known Member

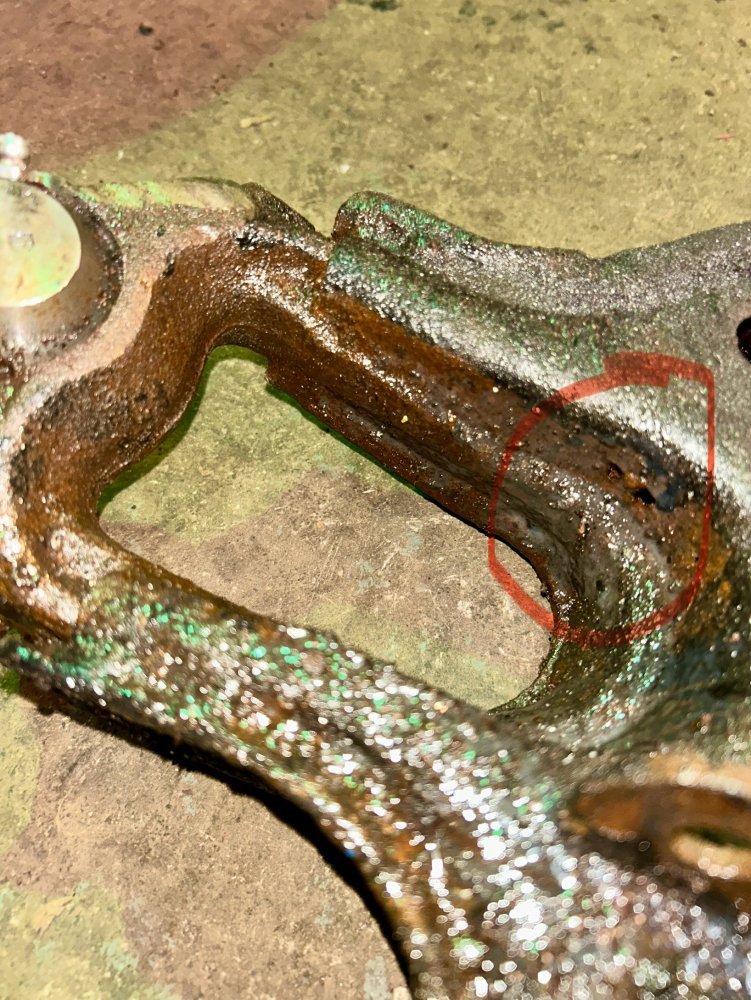

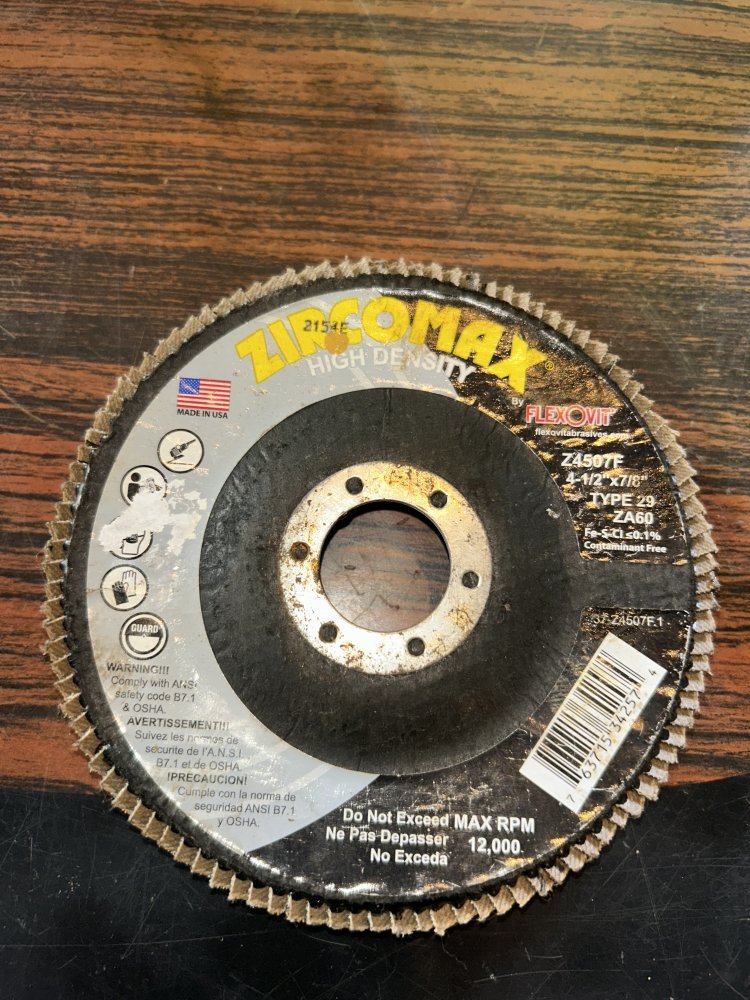

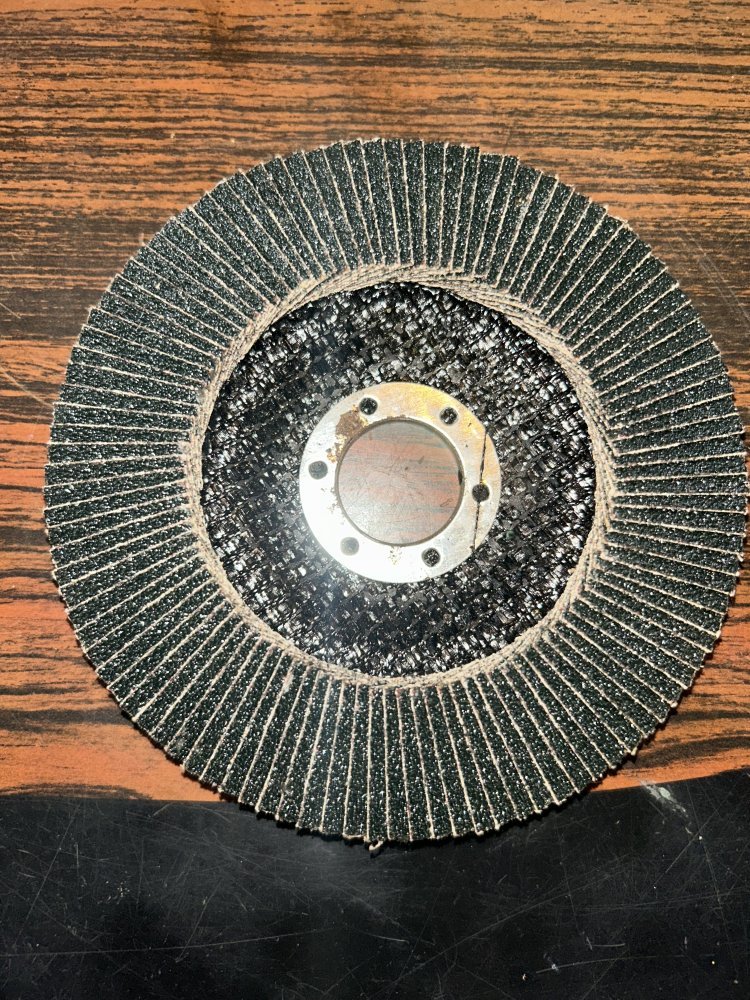

I used a grinder with cut off disc. It will do the job. There is no going back on this.Last night I attempted to get the driver side lower control arm removed on my 96 Chevy.Everything is off at this point.Had no trouble getting the lower bolts out of the bushings.

I used a Milwaukee reciprocating saw to slice down through the control arm in the torsion bar area in an attempt to split it but the blade would only cut down so far and not cut any further so I’m thinking the part that would not cut must be tempered or case hardened where the torsion bar enters.

I used Diablo cutting blades with lots of spray lube to keep the blade from overheating.It was pretty easy cutting down through the control arm until a certain point.Before throwing out the control arms I’ll just have to press out the new ball joints I have in place.

I’ll have to use a grinder with the thin cut off disc tomorrow to get down a little deeper and then i should be able to hammer the control arm off.I’ll post some pictures of how it looks when i finally get it off.

The stamped steel lower control arms (LCA) get rusted on the torsion bars. The forged LCAs never rust on the torsion bars and are easy to get off.