Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome to The Truck Stop! We see you haven't REGISTERED yet.

Your truck knowledge is missing!

- Registration is FREE , all we need is your birthday and email. (We don't share ANY data with ANYONE)

- We have tons of knowledge here for your diesel truck!

- Post your own topics and reply to existing threads to help others out!

- NO ADS! The site is fully functional and ad free!

Problems registering? Click here to contact us!

Already registered, but need a PASSWORD RESET? CLICK HERE TO RESET YOUR PASSWORD!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rebuild about done

- Thread starter Rodd

- Start date

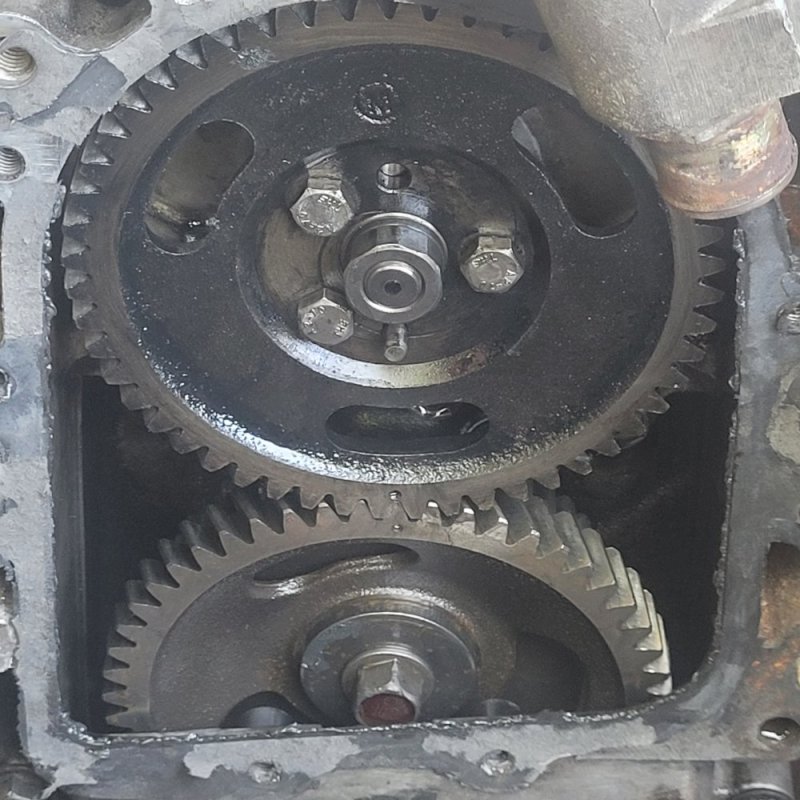

That pic shows the IP gear is right, BUT without seeing the timing gear behind it I can't be sure the crank & cam are right... Pull the cover, remove the 2 IP gears, then line up the dots on the timing gears, post a pic so I can see where the keyways are...

Rodd

Recruit

From the picture the dot on the gear in back lines up with the front, but it looks like the dot on the crankshaft gear may be off one tooth if I'm looking at it correctly.

Attachments

You still need to take the 2 IP gears off, I think your timing gears are off. With the 2 timing gears off the timing gears dots should line up a certain way with the keys a certain way.

The crank gear key should be @ 2 o'clock, the cam key @ 3 o'clock, crank dot @ 12 o'clock, cam dot @ 6 o'clock lined up....

Then install the cam IP gear and rotate the crank 1 full turn clockwise and the dot on the IP cam gear will be @ 12 o'clock, install the top IP gear, dot @ 6 o'clock lined up, the pin in the pump will be @ 6 o'clock.

Don't forget to use loctight on everything.

Then install the cam IP gear and rotate the crank 1 full turn clockwise and the dot on the IP cam gear will be @ 12 o'clock, install the top IP gear, dot @ 6 o'clock lined up, the pin in the pump will be @ 6 o'clock.

Don't forget to use loctight on everything.

Rodd

Recruit

Your pic proves what I have said in the past, the dot on the cam gear is miss located, I have seen this with these gear drives, hence why I go through the process to degree the cam.

A educated guess would be to move the cam counter clockwise 1 tooth, but without going through the process it's just a guess...

Your 2nd pic shows the crank gear dot is NOT @ 12 o'clock, your gears are not right...

A educated guess would be to move the cam counter clockwise 1 tooth, but without going through the process it's just a guess...

Your 2nd pic shows the crank gear dot is NOT @ 12 o'clock, your gears are not right...

My honest suggestion in your case sense you don't know how OR have the equipment to degree the cam, ie get things right the head needs to come off, would be to use a timing chain and not the gears, you are going to risk major damage if you keep guessing just to have the gears.... remember these are called ZERO clearance motors for a reason..

Rodd

Recruit

So basically since the center and lower gears have keyways those are correct. The issue is the IP gear and if you rotate the pump gear one tooth one way it fixes the issue but if you go one tooth the wrong way it becomes a boat anchor, correct?

No, the timing gears are where the trouble is, moving the IP gears and not the gear set won't fix anything.

Rodd

Recruit

got it. I just ordered a set from rockauto.No, the timing gears are where the trouble is, moving the IP gears and not the gear set won't fix anything.

Will L.

Well-Known Member

If you install a stock timing chain/gear set. Then without turning the crank or cam- slide them off and slide on the gear drive- you will be correct.

Degreeing the cam is ideal.

Degreeing the cam is ideal.

dbrannon79

I'm getting there!

I hadn't thought about it that way but that makes perfect sense. installing and setting up a regular timing chain set so it's on the money, then without moving anything slide it off and putting the gear set back on...If you install a stock timing chain/gear set. Then without turning the crank or cam- slide them off and slide on the gear drive- you will be correct.

Degreeing the cam is ideal.

@Rodd if you do try this. post a pic of the chain set installed and lined up, then another with the gear set slid back on without moving the crank or cam. you can take a paint marker and dot the crank and cam where the dots are on the chain set so we can reference the diference on how the gear set is mis-dotted. then make you some dots on the gear set so later down the road you have the correct marks on it in the event you ever have to pull it apart again.

Will L.

Well-Known Member

Making the dots is as simple as marker when on the engine, slide off and set on bench. Center punch then start to use a 3/16 or so drill bit. Just enough to make the dot.

Something I am contemplating is putting my cam gear on a lathe and removing a lot of the gear face so it is the same basic profile as the stock gear.

The weight is not a good thing for performance. Really shouldn’t hurt anything but won’t hurt to lighten it either.

Something I am contemplating is putting my cam gear on a lathe and removing a lot of the gear face so it is the same basic profile as the stock gear.

The weight is not a good thing for performance. Really shouldn’t hurt anything but won’t hurt to lighten it either.

Rodd

Recruit

good Idea. I will cancel my order.If you install a stock timing chain/gear set. Then without turning the crank or cam- slide them off and slide on the gear drive- you will be correct.

Degreeing the cam is ideal.

Rodd

Recruit

Making the dots is as simple as marker when on the engine, slide off and set on bench. Center punch then start to use a 3/16 or so drill bit. Just enough to make the dot.

Something I am contemplating is putting my cam gear on a lathe and removing a lot of the gear face so it is the same basic profile as the stock gear.

The weight is not a good thing for performance. Really shouldn’t hurt anything but won’t hurt to lighten it either.

will do. Thanks!I hadn't thought about it that way but that makes perfect sense. installing and setting up a regular timing chain set so it's on the money, then without moving anything slide it off and putting the gear set back on...

@Rodd if you do try this. post a pic of the chain set installed and lined up, then another with the gear set slid back on without moving the crank or cam. you can take a paint marker and dot the crank and cam where the dots are on the chain set so we can reference the diference on how the gear set is mis-dotted. then make you some dots on the gear set so later down the road you have the correct marks on it in the event you ever have to pull it apart again.

MrMarty51

Well-Known Member

Anxiously watching this thread to see how the gear set marks aligns with the marks on the sprockets.

dbrannon79

I'm getting there!

Rodd

Recruit

The plan is to do it this weekend.

Rodd

Recruit

My son texted me this picture after using tho old gear and chain to set timing. He then took it off the time keeper. Unfortunately he didn't take a picture with the chain. He thinks he installed the time keeper off by 1 tooth originally. How does it look?