Rodd

Recruit

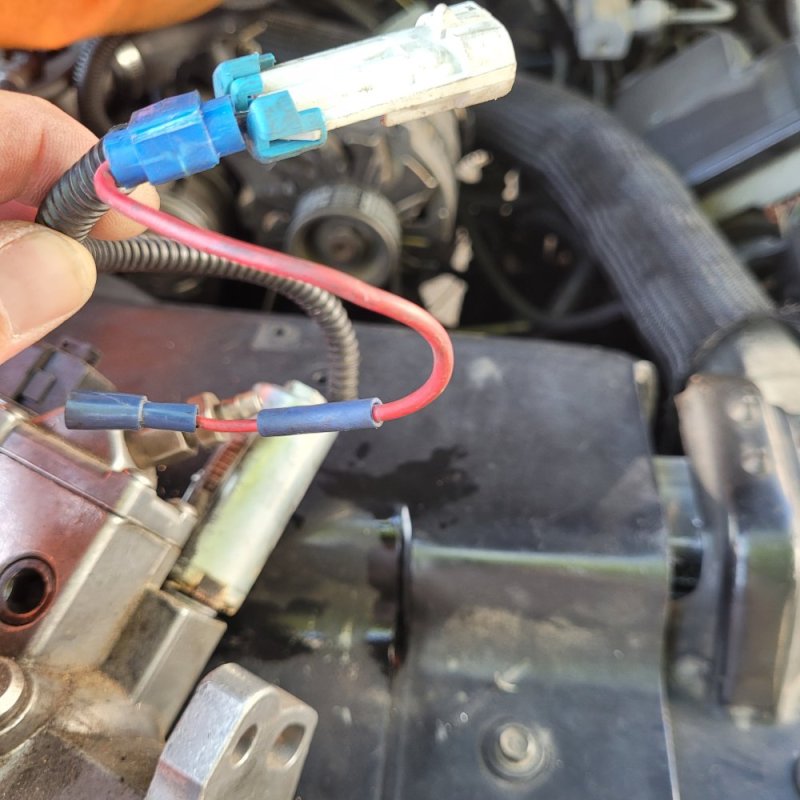

Thanks guys. The starter is one from Autozone. I'm wondering if my son used the wrong bolts when he installed it. I know I had everything lableled. He knows to install that little bracket on the end of the starter. I told him if he doesn't it will crack the block with the starter weight. I better double check.