FellowTraveler

Well-Known Member

Progress w/12 valve conversion has been slow but sure.

Lots of parts sitting on the bench waiting for install. At issue is most of my tools were submerged in salt flood waters during hurricane Hermain cleanup here still not finished then there is 600’ of shoreline debris to contend with.

Most recent parts addition is a COMPUSHIFT MINI CONTROLLER which will effortlessly handle lockup & overdrive after I address an old issue all early 12 valves had with the TPS bushing wear causing throttle shaft to wobble around interfering with TPS output in turn causing erratic shifting LU/OD problems I used brass bushings to solve the problem. Yes, I could have just went with two toggle switches for control of LU/OD however I like redundant so I’ll have the two switches isolated via a manual lockout device, if all fails I can still drive “slower” w/3 gears.

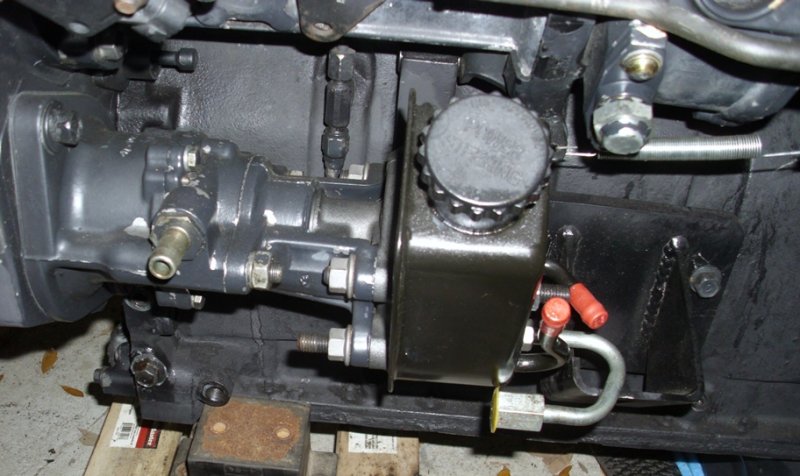

I purchased a re-manufactured RH47 4X4 overdrive unit to convert from 2wd it will be attached to a late model NP241 w/40 tooth tone ring tail section for VSSB etc. I have to change out the t-case input shaft from GM 32 spline to Dodge/Jeep 23 spline input.

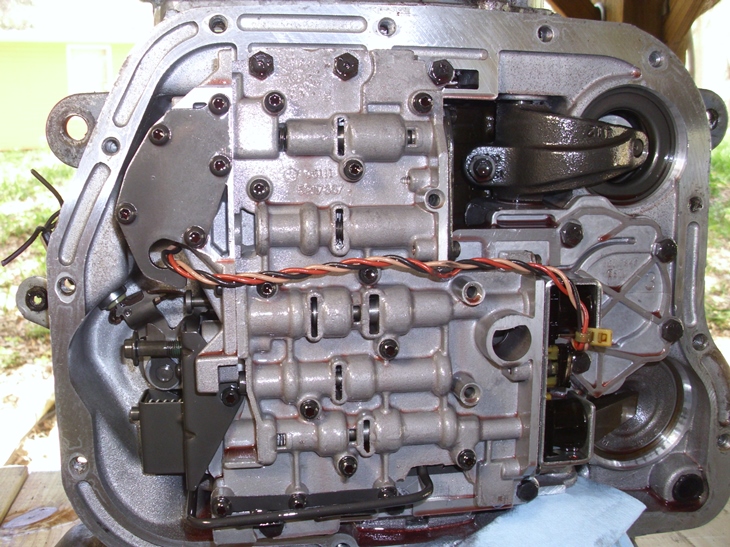

TransGo TOFD diesel shift kit is my choice for valve body mods going with firm shifts etc.

The jury is out as to whether or not to relocate the vent on the 47RH which is at top of front pump to the top of the case for easy vent hose attachment and routing up high in engine bay then there is the 4X4 OD unit with its lower vent grove between it and the t-case and considering sealing the grove and placing a vent on top of it too. I will have to use a clocking ring and still don’t know if I’ll have issues with the driver’s side starter on the 12 valve I’m thinking not but I can always lower the front diff 2” or so.

The RH47 was used for only two years so some parts are at a premium but I like the hydraulic control.

I’m almost done with the 12 valve, today is valve adjustment day followed by injection pump install & timing. I opted to go with a metal timing pin instead of the plastic one that is stock on the 12 valve.

My 4” exhaust will use the Cummins cobra-head down pipe. I’m still mulling around how to get the HX super 40 to spool ‘down low’ considering my exhaust manifold is centered & split 3x3 cylinders to dual volute T-3 configuration.

Have a TINY TACH w/hour meter and injection line transducer (6mm) for most accurate RPM reading so it will be useful when I play with pulley diameter on the GM GEN/ALT to get a better reading on the dash tach, yep redundant again.

Using updated Ram IP throttle cable new throttle valve cable & GM shifter cable which has to come in from the front of the 47RH to work so bracket fab is a must.

I picked up a GM cruise control box w/attached cable & harness.

Intake runner powder coated.

Suggestions welcome.

Lots of parts sitting on the bench waiting for install. At issue is most of my tools were submerged in salt flood waters during hurricane Hermain cleanup here still not finished then there is 600’ of shoreline debris to contend with.

Most recent parts addition is a COMPUSHIFT MINI CONTROLLER which will effortlessly handle lockup & overdrive after I address an old issue all early 12 valves had with the TPS bushing wear causing throttle shaft to wobble around interfering with TPS output in turn causing erratic shifting LU/OD problems I used brass bushings to solve the problem. Yes, I could have just went with two toggle switches for control of LU/OD however I like redundant so I’ll have the two switches isolated via a manual lockout device, if all fails I can still drive “slower” w/3 gears.

I purchased a re-manufactured RH47 4X4 overdrive unit to convert from 2wd it will be attached to a late model NP241 w/40 tooth tone ring tail section for VSSB etc. I have to change out the t-case input shaft from GM 32 spline to Dodge/Jeep 23 spline input.

TransGo TOFD diesel shift kit is my choice for valve body mods going with firm shifts etc.

The jury is out as to whether or not to relocate the vent on the 47RH which is at top of front pump to the top of the case for easy vent hose attachment and routing up high in engine bay then there is the 4X4 OD unit with its lower vent grove between it and the t-case and considering sealing the grove and placing a vent on top of it too. I will have to use a clocking ring and still don’t know if I’ll have issues with the driver’s side starter on the 12 valve I’m thinking not but I can always lower the front diff 2” or so.

The RH47 was used for only two years so some parts are at a premium but I like the hydraulic control.

I’m almost done with the 12 valve, today is valve adjustment day followed by injection pump install & timing. I opted to go with a metal timing pin instead of the plastic one that is stock on the 12 valve.

My 4” exhaust will use the Cummins cobra-head down pipe. I’m still mulling around how to get the HX super 40 to spool ‘down low’ considering my exhaust manifold is centered & split 3x3 cylinders to dual volute T-3 configuration.

Have a TINY TACH w/hour meter and injection line transducer (6mm) for most accurate RPM reading so it will be useful when I play with pulley diameter on the GM GEN/ALT to get a better reading on the dash tach, yep redundant again.

Using updated Ram IP throttle cable new throttle valve cable & GM shifter cable which has to come in from the front of the 47RH to work so bracket fab is a must.

I picked up a GM cruise control box w/attached cable & harness.

Intake runner powder coated.

Suggestions welcome.