Will L.

Well-Known Member

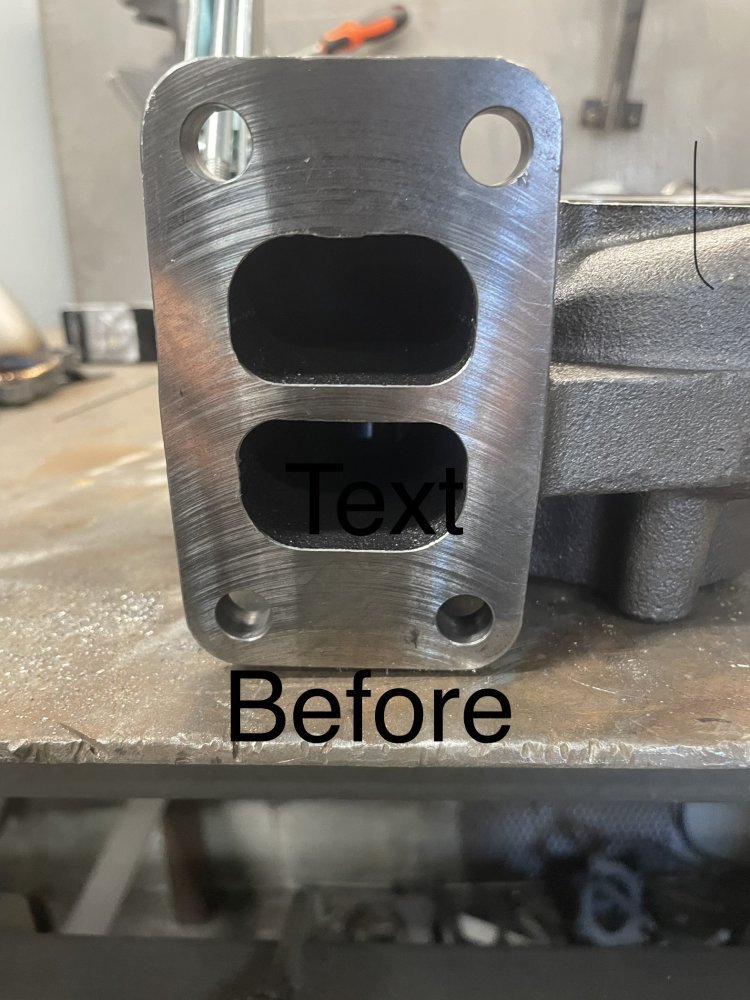

Yes, the divided housing is too cause a faster spool but the division causes a little loss on top end. Help one area and it hurts another. No free lunches. There are types of a QSV that blocks one side of the twin scroll to get the similar effect.

The progression from there is to a variable vein turbo to get the best of both worlds. Thats whats on the new diesel trucks. But now a computer and a stack of sensors feeding it to control the turbo. And the soot eating egr then helps mess them up.

I don’t know of many folks to have put vvt on the 6.5. @Twisted Steel Performance has a nifty one on his wazoo p400. Controlling it is the challenge.

Many of the controllers fall short - I am anxiously awaiting to see this one is dialed in. A bit out of my price range unfortunately. Then again, some say when dealing with the wife it’s better to ask forgiveness than permission…

The progression from there is to a variable vein turbo to get the best of both worlds. Thats whats on the new diesel trucks. But now a computer and a stack of sensors feeding it to control the turbo. And the soot eating egr then helps mess them up.

I don’t know of many folks to have put vvt on the 6.5. @Twisted Steel Performance has a nifty one on his wazoo p400. Controlling it is the challenge.

Many of the controllers fall short - I am anxiously awaiting to see this one is dialed in. A bit out of my price range unfortunately. Then again, some say when dealing with the wife it’s better to ask forgiveness than permission…