FellowTraveler

Well-Known Member

With the Evans, is there any direct comparison of temperature you can tell us? Something like: on a particular road/hill you always drive it would climb to 215, but now it does "x".

My other thought is for my off roading- my windshield washer tank has a tiny breather hole and leaks out when I go at angles. I know your supposed to drill a hole in the radiator cap for Evans, and I'm gonna leak out there like the windshield fluid. I am trying to figure a double p trap set up to solve that, but nothing came to mind I like.

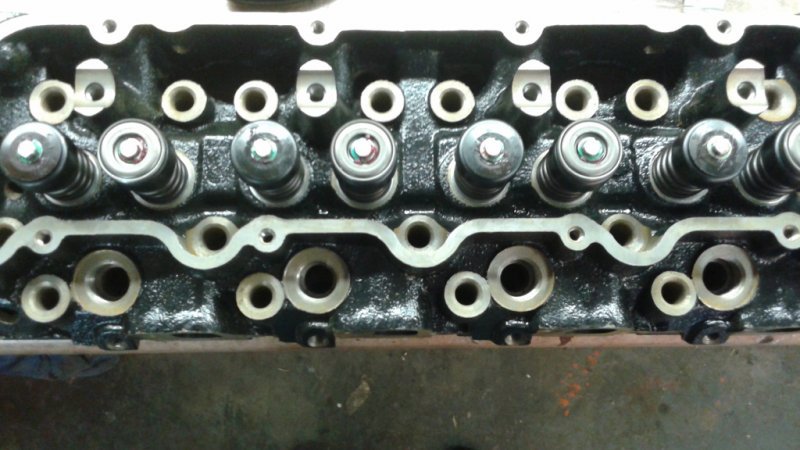

Keep in mind your coolant temp gauge will not really sense the excessive heat created through the steaming of EGW and elevated EGT's with any accuracy. A search in any search engine of cavitation and steaming of EGW coolants will provide a wealth of usable facts. GM has designed steam venting lines into the later 6.5td and the LS series gas engines because of the steaming problems.

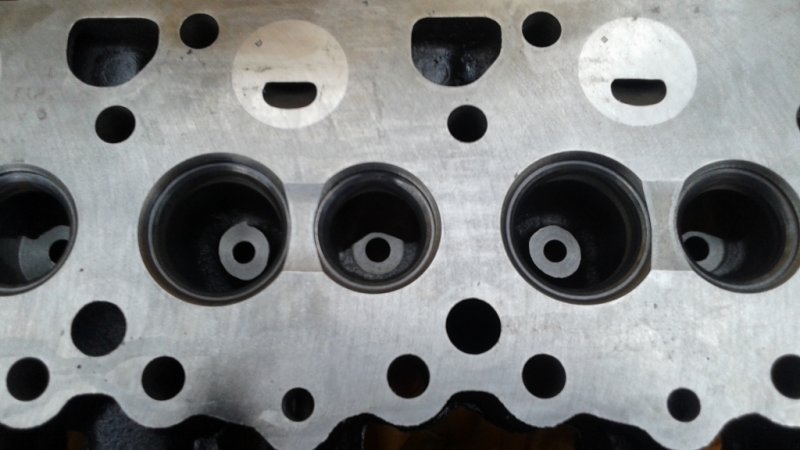

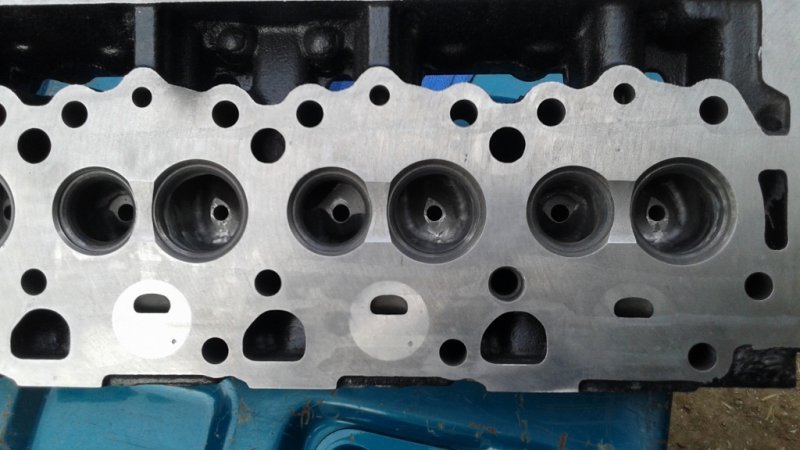

After the CKO HX40 temps are even more stable, as hills go not many to speak of here but w/EGW I saw 225+ deg. f under load a few times while running AC now the temps are lower and stable. I read a lot and then make up my mind as to what I'd like to accomplish for any project. As I understand the steaming, cavitation from the water in EGW so it is the smoking gun in many heat related failures of cylinder heads and blocks.

Vent caps to breather hoses by installing a hose fitting would be a good practice in your situation. As caps go EVANS sells the zero pressure cap.

There are overflow tanks on some applications and accumulator tanks on others like the later GM diesels and LS series engines the coolant level is usually about 1/2 to 2/3rds the height of the tank overfilled it will leak on expansion of coolant as it will with air being pumped into cooling system.

Last edited: