I thought the whole point of including the new cooler was that a majority of the time the old one strips upon dissasembly. One improvement I would like to see it a different fitting used at the block. I used a similar kit to what you sell(before you were even selling them) and it used the same fittings at the block and I did not like them. It was difficult to get them at the right angle so's the lines would not rub the 4x4 adaptor. There is no real way to "lock" them in exactly the right spot. You either have to crank them tighter than I feel comfortable doing or not quite tight enough and then they loosen and leak later on. Not knocking your product, in fact I used a similar one not yours but I would like to see a better way at the block. Some sort of fitting that could be clocked the3 way it needs to be then locked down tight...does that make sense ?? I may be wording this poorly.

I think what you are thinking about is straight pipe thread and uses a o-ring ,washer and jamb nut. This set-up is used a lot on hydraulic valves and other hydraulics. Our blocks weren't machined for this type of fitting unfortunately. Not enough room to go with a pipe to JIC swivel either.

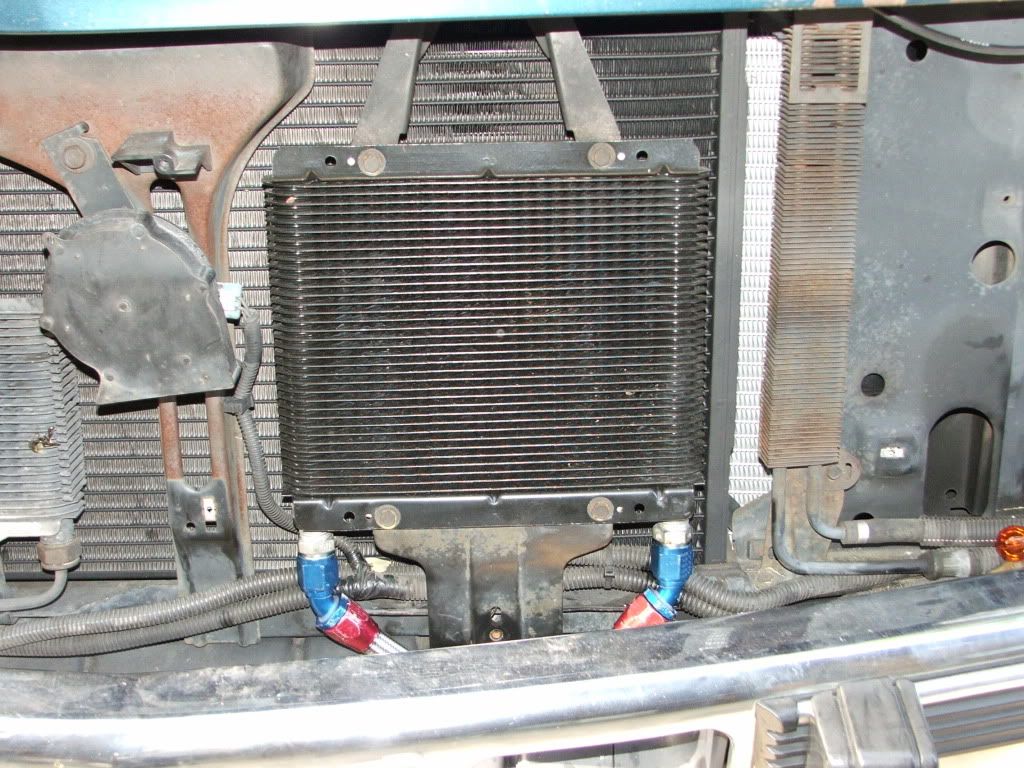

I have stripped out the threads in the cooler fittings. Pipe threads in aluminum just plain sucks. I'm a big fan of the swivel fittings that Leroy sells. For me, trying to clock the 45degree elbows correctly ,the first time[and leak free], is near impossible.