I need to read this thread from the beginning

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome to The Truck Stop! We see you haven't REGISTERED yet.

Your truck knowledge is missing!

- Registration is FREE , all we need is your birthday and email. (We don't share ANY data with ANYONE)

- We have tons of knowledge here for your diesel truck!

- Post your own topics and reply to existing threads to help others out!

- NO ADS! The site is fully functional and ad free!

Problems registering? Click here to contact us!

Already registered, but need a PASSWORD RESET? CLICK HERE TO RESET YOUR PASSWORD!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Working on a "next-level" fuel system

- Thread starter n8in8or

- Start date

Hey guys' I've been thinking about and researching a little info on the Boost Referenced FPRs and came across a little downfall of it's use on a diesel engine. If you have a tube going from anywhere just about on the intake system for boost pressure reference to the topside of the rubber diaphragm on the FPR and it ruptures and your lift pump is pumping a steady let' say 20psi and you are at idle or low boost it will pump diesel fuel into the intake and what happens next? Uncontrollable fuel and air into the engine which = run away! I know there probably are some sort of one way check valves that may be installed but will they work properly and is it worth the risk?

n8in8or

I never met a project I didn’t like

Good thought. It’s only worth the risk if it is proven that the extra pressure will do anything for us - that has yet to be proven on a DB2 application.Hey guys' I've been thinking about and researching a little info on the Boost Referenced FPRs and came across a little downfall of it's use on a diesel engine. If you have a tube going from anywhere just about on the intake system for boost pressure reference to the topside of the rubber diaphragm on the FPR and it ruptures and your lift pump is pumping a steady let' say 20psi and you are at idle or low boost it will pump diesel fuel into the intake and what happens next? Uncontrollable fuel and air into the engine which = run away! I know there probably are some sort of one way check valves that may be installed but will they work properly and is it worth the risk?

Isn't the idea behind it to only increase volume and pressure when needed under load to the IP thus reducing wear tear and added stress to the LP? Can't too much pressure @ low demand cause ill affects and or timing changes to the IP? Look at the working's of the Fass FPR, I now know why the first guy told me it will only raise the pressure. When either spring pressure or upper housing pressure is put on the topside of the diaphragm and aluminum piece, it just shuts off flow to the return line like a float needle and seat in a carburetor thus increasing volume and pressure to the IP . Unlike a FPR without a return port would just restrict flow thus increasing pressure but reducing volume, correct?

FellowTraveler

Well-Known Member

The IP is designed w/overflow-return unlike a carburetor 'I suspect closing off the overflow/return even momentary would cause other issues.'Isn't the idea behind it to only increase volume and pressure when needed under load to the IP thus reducing wear tear and added stress to the LP? Can't too much pressure @ low demand cause ill affects and or timing changes to the IP? Look at the working's of the Fass FPR, I now know why the first guy told me it will only raise the pressure. When either spring pressure or upper housing pressure is put on the topside of the diaphragm and aluminum piece, it just shuts off flow to the return line like a float needle and seat in a carburetor thus increasing volume and pressure to the IP . Unlike a FPR without a return port would just restrict flow thus increasing pressure but reducing volume, correct?

n8in8or

I never met a project I didn’t like

Isn't the idea behind it to only increase volume and pressure when needed under load to the IP thus reducing wear tear and added stress to the LP? Can't too much pressure @ low demand cause ill affects and or timing changes to the IP? Look at the working's of the Fass FPR, I now know why the first guy told me it will only raise the pressure. When either spring pressure or upper housing pressure is put on the topside of the diaphragm and aluminum piece, it just shuts off flow to the return line like a float needle and seat in a carburetor thus increasing volume and pressure to the IP . Unlike a FPR without a return port would just restrict flow thus increasing pressure but reducing volume, correct?

Yes, that is how the boost referenced regulator works. What I’m saying is it is yet to be proven whether there is a benefit to manipulating the inlet pressure to a DB2 IP. The IP is calibrated to work with a certain inlet pressure. Changing that inlet pressure may not have much affect on the outlet pressure without other IP modifications.....or it might, I don’t know. Someone knows I’m sure, but it hasn’t been shared in this thread. The one thing I do know is that changing the inlet pressure will affect the injection timing of the pump. That is something that would have to be looked at very closely. So while the rising rate regulator is a neat idea and MAY have a cool use for performance, that has yet to be proven so I don’t think it should be the main focus. It would be nice to get a regulator with that boost reference port for future playing, but I don’t see that as a priority. The return style regulator itself should go a long way to stabilizing fuel pressure and that is the most important thing-at least in my eyes.

I have tried pinching off my return hose in an effort to come up with an external timing advance mechanism and even before you fully clamp it off it kills the engine.The IP is designed w/overflow-return unlike a carburetor 'I suspect closing off the overflow/return even momentary would cause other issues.'

We are talking about adding a dedicated return line and not touching the existing OEM return system. At least that's what I was meaning in my previous post, sorry for the confusion.The IP is designed w/overflow-return unlike a carburetor 'I suspect closing off the overflow/return even momentary would cause other issues.'

ak diesel driver

6.5 driver

one of the ford guys used one of the boost referenced FPR on his DB2 said it made a noticeable difference. Might talk to R&D and see what info he has as he builds high output db2s for the ford guys

Will L.

Well-Known Member

No knowledge just thinking steady pressure was best. That’s what we did back on the covered wagon days, but doesn’t mean it was best.

On the runaway from problem- HECK YEAH that is possible.

2 things here:

1. Maybe install an isolater like the one Leroy sells (or used to sell)

2. My hotrod trails I had 3 runaways. The first one was helpful on my e.t.- good run! Then it stuck a rod in the racetrack right at the traps. The next two runaways I pulled a cable and blocked airflow killing engine. Yup- only took one time and that eneded that. I would like to put a safety on the hummer, but a little pricey. I keep thinking about homemade affordable one.

On the runaway from problem- HECK YEAH that is possible.

2 things here:

1. Maybe install an isolater like the one Leroy sells (or used to sell)

2. My hotrod trails I had 3 runaways. The first one was helpful on my e.t.- good run! Then it stuck a rod in the racetrack right at the traps. The next two runaways I pulled a cable and blocked airflow killing engine. Yup- only took one time and that eneded that. I would like to put a safety on the hummer, but a little pricey. I keep thinking about homemade affordable one.

n8in8or

I never met a project I didn’t like

The isolator is a top-notch idea. I dig.No knowledge just thinking steady pressure was best. That’s what we did back on the covered wagon days, but doesn’t mean it was best.

On the runaway from problem- HECK YEAH that is possible.

2 things here:

1. Maybe install an isolater like the one Leroy sells (or used to sell)

2. My hotrod trails I had 3 runaways. The first one was helpful on my e.t.- good run! Then it stuck a rod in the racetrack right at the traps. The next two runaways I pulled a cable and blocked airflow killing engine. Yup- only took one time and that eneded that. I would like to put a safety on the hummer, but a little pricey. I keep thinking about homemade affordable one.

FellowTraveler

Well-Known Member

Perhaps a Bosch p7100 or other series for an 8 cylinder application would be the ultimate and much easier to tune too, however it would be a custom fabrication on a 6.2/6.5 IDI.

https://www.google.com/search?q=Bos...dAhVKy1MKHVahC98QsAR6BAgGEAE&biw=1366&bih=632

https://www.google.com/search?q=Bos...dAhVKy1MKHVahC98QsAR6BAgGEAE&biw=1366&bih=632

Last edited:

Hey Will, do you remember what the intended use was for on the isolator the Leroy may have had?No knowledge just thinking steady pressure was best. That’s what we did back on the covered wagon days, but doesn’t mean it was best.

On the runaway from problem- HECK YEAH that is possible.

2 things here:

1. Maybe install an isolater like the one Leroy sells (or used to sell)

2. My hotrod trails I had 3 runaways. The first one was helpful on my e.t.- good run! Then it stuck a rod in the racetrack right at the traps. The next two runaways I pulled a cable and blocked airflow killing engine. Yup- only took one time and that eneded that. I would like to put a safety on the hummer, but a little pricey. I keep thinking about homemade affordable one.

Will L.

Well-Known Member

Fuel pressure gauge. It’s so you can use a mechanical gauge, but no fuel enters the cabin.

I remember he stocked them. But talked about not carrying them long term, probably cuz not enough people understand how much money it saved long term to install a pressure gauge. Or too many folks like me that will run a diesel line into my cab and won’t panic if a gallon sprays on me- free cologne- haha.

I remember he stocked them. But talked about not carrying them long term, probably cuz not enough people understand how much money it saved long term to install a pressure gauge. Or too many folks like me that will run a diesel line into my cab and won’t panic if a gallon sprays on me- free cologne- haha.

The better gauge manufactures have them in the kits also... A electronic gauge works as good for this application..

I got a brass fitting today with a one way ball valve with a 1/8" NPT thread so it threads right into the FPR. It takes 3psi to pop the ball loose. I know because naturally the first think I did was blow into it each way and it didn't just flow free. I still don't like the idea of a $17.00 ball valve as engine insurance so to speak, I realize at least with the ball valve two items would have to fail to get fuel into the intake. If I use this FPR and run a dedicated return line I'm going to have to start a thread named the most expensive fuel system. LOL

FellowTraveler

Well-Known Member

I have the Auto Meter fuel gauge isolator that uses anti freeze solution between it and mechanical fuel pressure gauge.....pricey but worth every cent.

93detroit

Well-Known Member

Hey Nate, any progress on your system? I haven't been on here in a while and I will admit struggling to comprehend everything that was talked about (my fuel system is stock and works for my needs right now, but I have talked to Conestoga about something better). Did you ask Mel if your pump was set up to handle 25psi input in low throttle/boost situations? Does it surge at idle/part throttle now? Or are you just concerned that it will happen with a higher volume lift pump? I apologize for my ignorance!

n8in8or

I never met a project I didn’t like

Hello. I worked with Mel’s old shop manager when setting this pump up. It is designed for a constant 25psi of inlet fuel pressure in all conditions. It has no surging at idle or part throttle. I’m not concerned about any problems with a larger volume lift pump - I’m trying to come up with a modestly proced fuel system that will provide the volume and pressure that the IP needs to put out maximum fuel - the current system can’t keep up so I’m leaving some power on the table.Hey Nate, any progress on your system? I haven't been on here in a while and I will admit struggling to comprehend everything that was talked about (my fuel system is stock and works for my needs right now, but I have talked to Conestoga about something better). Did you ask Mel if your pump was set up to handle 25psi input in low throttle/boost situations? Does it surge at idle/part throttle now? Or are you just concerned that it will happen with a higher volume lift pump? I apologize for my ignorance!

n8in8or

I never met a project I didn’t like

Oh and no, I haven’t made any progress on the fuel system yet....I’m still working on the body restoration portion of the project.

Quadstar Tuning LLC

Quadstar Tuning LLC

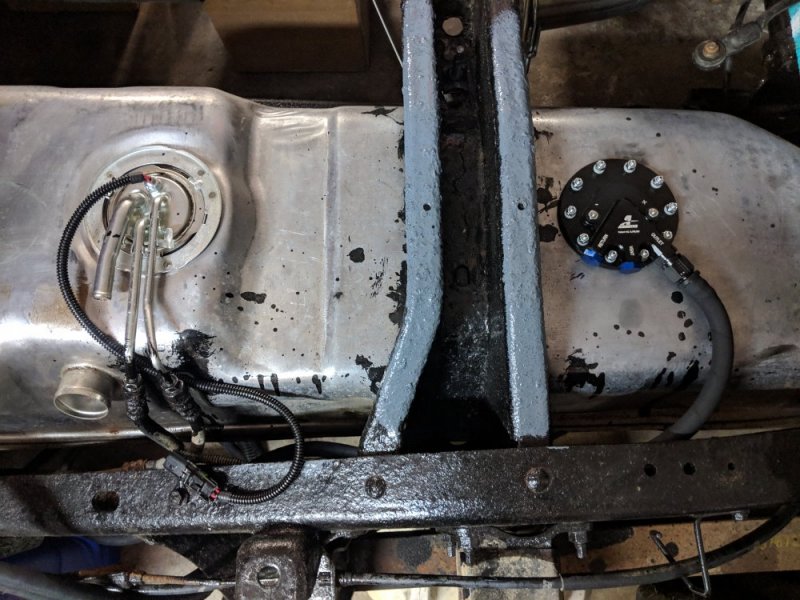

Step away from the norm and try things that are more unique. The manufacturers don't always have all the answers, especially for a 20+ year old application. These can have a pre set regulator in the fuel bucket inside the tank or an external regulator with dedicated return. We run 1/2" line up to the primary spin on filter to eliminate any pressure drop that's present with smaller line. Dead quiet, simple and reliable with very little amp draw to boot.