- Staff

- #1

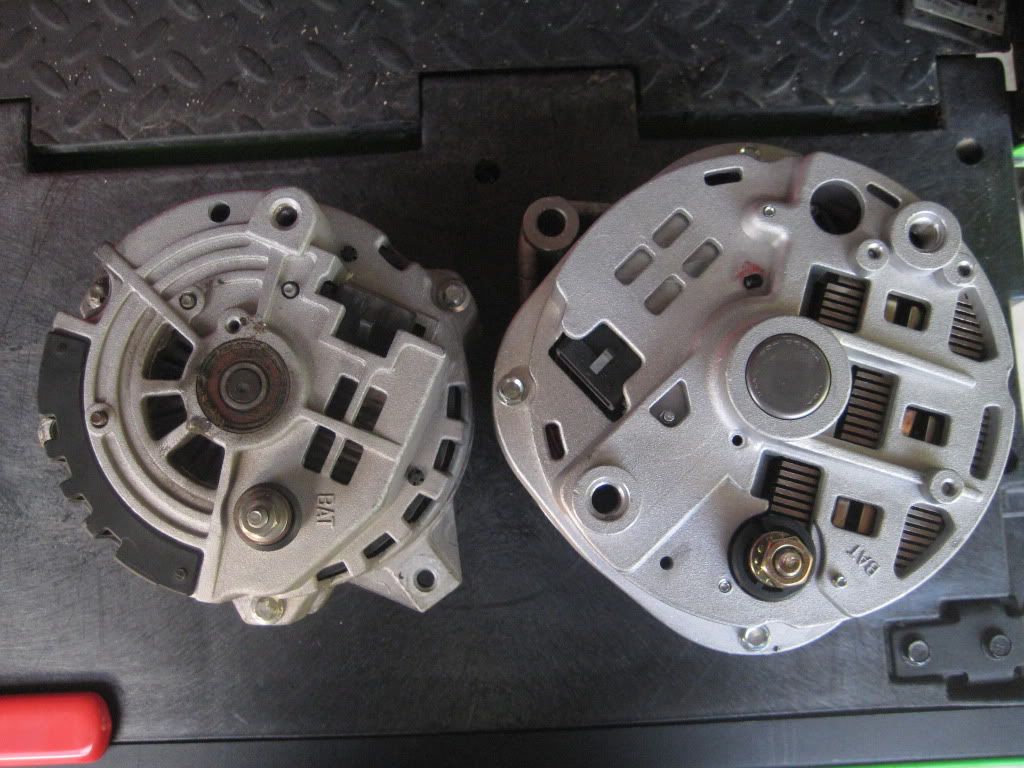

This thread will be continuously updated over the weekend till I get everything completed. I will start with this picture:

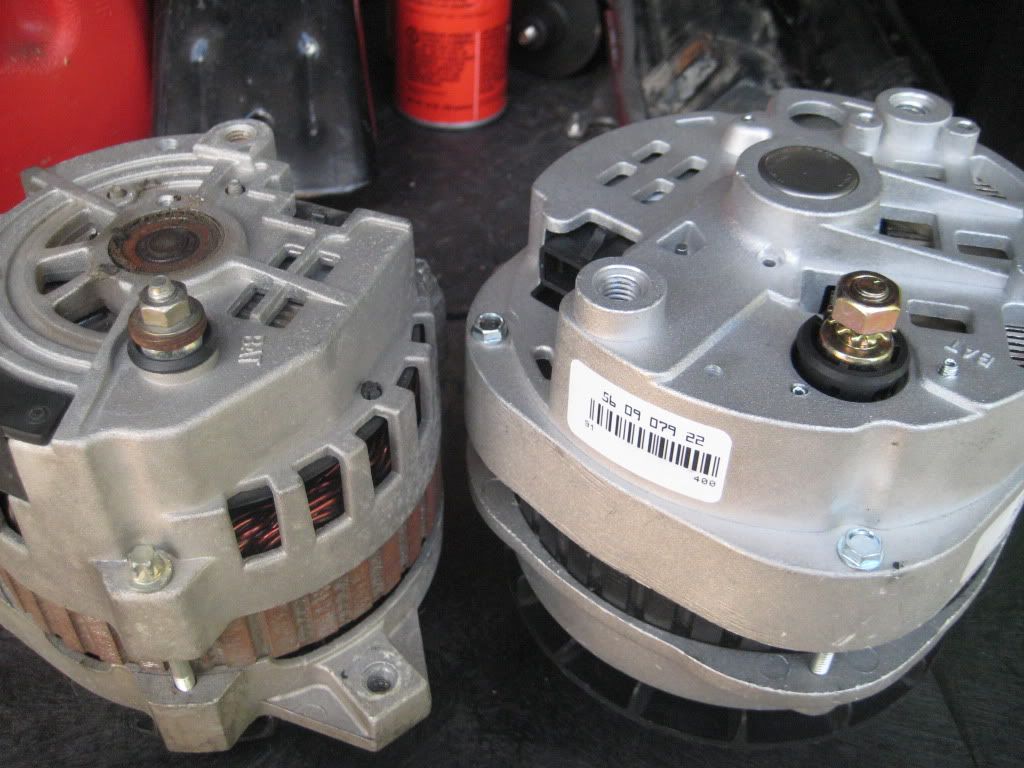

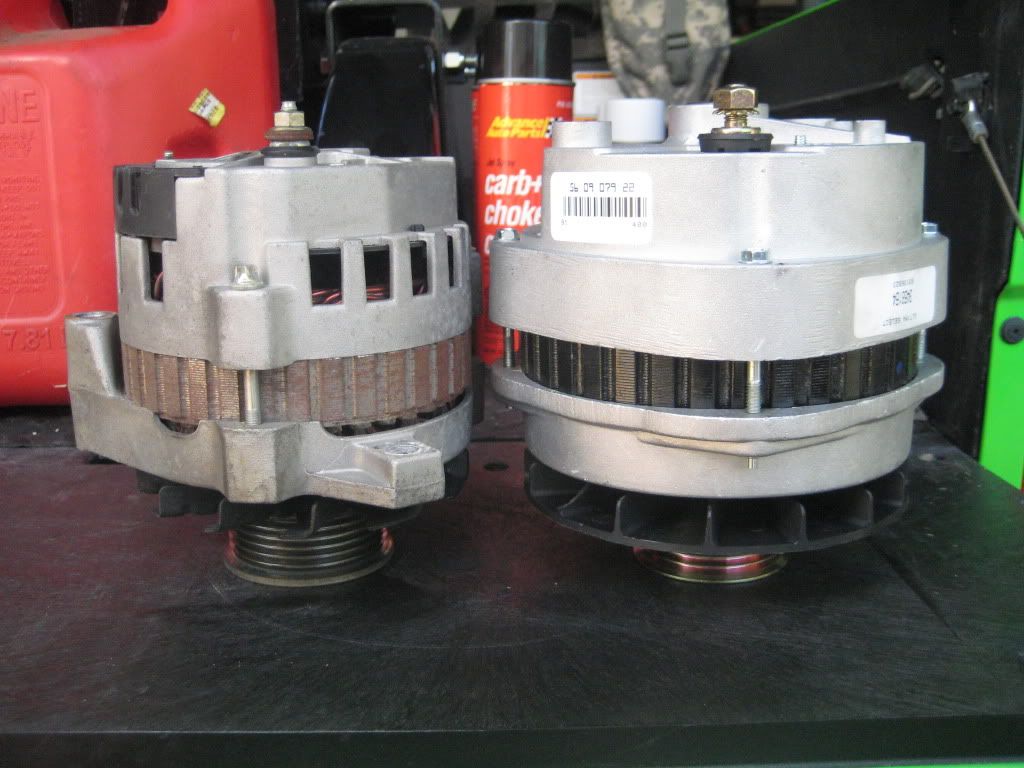

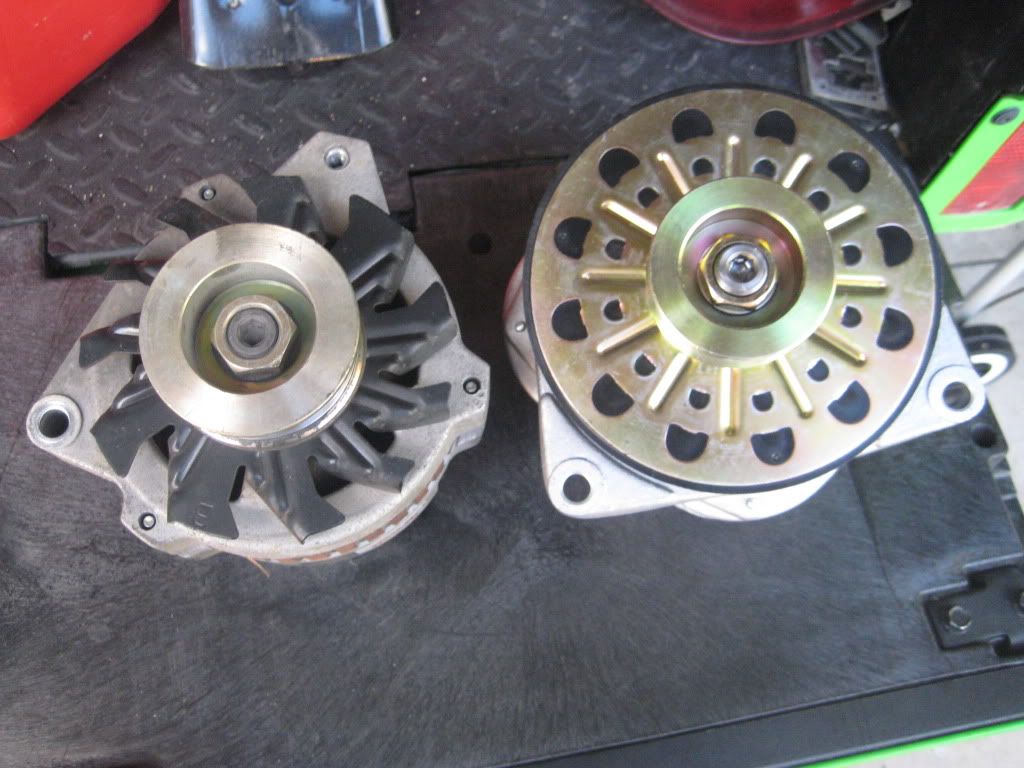

That is a brand new CS-144 Alternator with a life time warranty. I only paid $162 for it including the $5 core and tax. That is also with my 10% military discount. :thumbsup:

I will take tons of pictures with a step by step how to for everybody to follow and hopefully help fellow TTS members.

I will start this out with what I currently have and the problems I am having.

That is a brand new CS-144 Alternator with a life time warranty. I only paid $162 for it including the $5 core and tax. That is also with my 10% military discount. :thumbsup:

I will take tons of pictures with a step by step how to for everybody to follow and hopefully help fellow TTS members.

I will start this out with what I currently have and the problems I am having.