Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome to The Truck Stop! We see you haven't REGISTERED yet.

Your truck knowledge is missing!

- Registration is FREE , all we need is your birthday and email. (We don't share ANY data with ANYONE)

- We have tons of knowledge here for your diesel truck!

- Post your own topics and reply to existing threads to help others out!

- NO ADS! The site is fully functional and ad free!

Problems registering? Click here to contact us!

Already registered, but need a PASSWORD RESET? CLICK HERE TO RESET YOUR PASSWORD!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PERMANENTLY MOUNTED PRE START OILER PUMP

- Thread starter spdgofast

- Start date

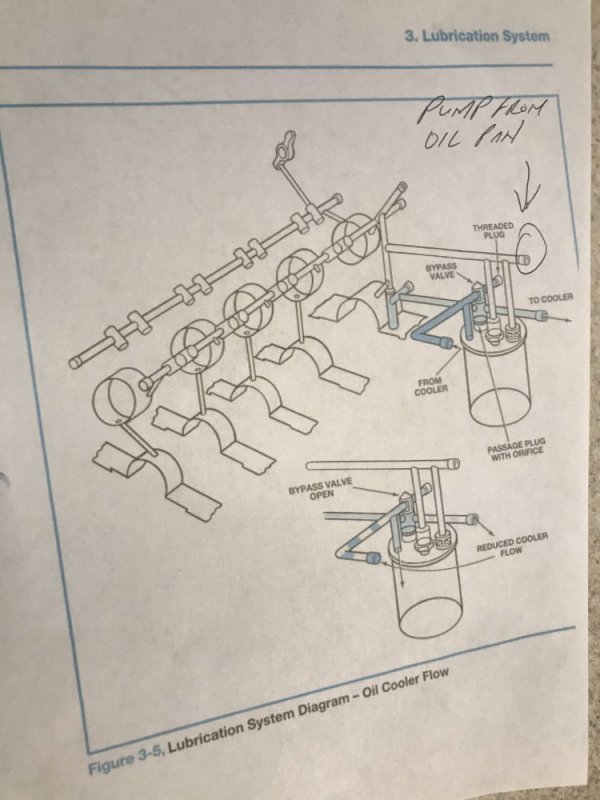

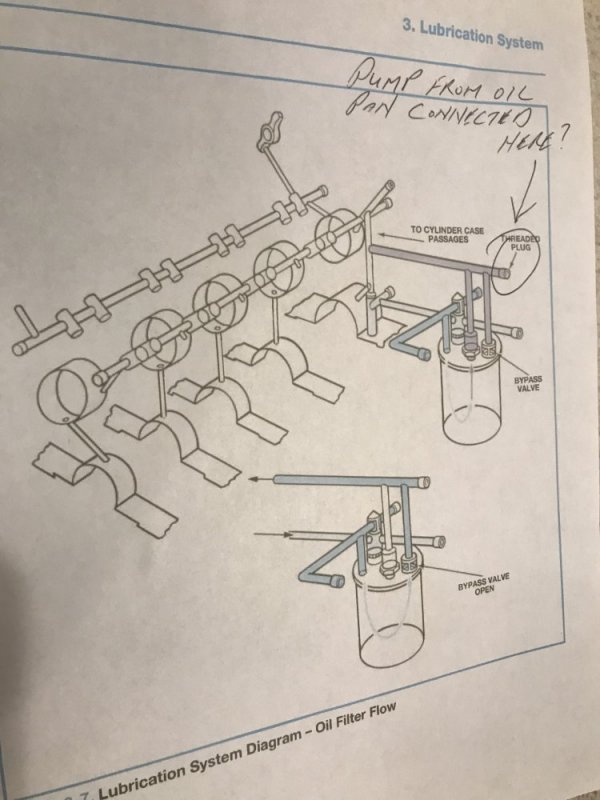

Hey Will, I know we have spoke of this before but this is the first time I've looked at the oil passage schematic, so it looks like the cam bearings get oil before all but one of the main bearings, so why do the cam bearings fail before the main bearings? See attached pics.I like preoiler/ oil accumulators.

A video of a guy that forgot to turn his on in road corse so one without then with. Watch the oil gauge.

This forum doesn’t see many that road corse, but offroad yes.

There are also people doing diy ones with an electric motor only for pre-start. Simple and provided quality hydraulic hoses are used will never suffer a reason to make the truck break down if it fails. I was thinking about doing electric motor to pre-oil before start, then using same pump for running a centrifuge to get the 110psi but too much stuff to fit in a hummer.

The 6.5 is ok with low pressure according to gm, but we saw them remove the loud cooling fan they needed for nuisance. They removed the numbers from the temperature gauge so warranty demands would be less, then later simply changed spec to a higher number which proved that omcost the military tons of engines.

Of the 6.5 I have seen Torn apart because of low oil pressure, cam bearings is where it went.

yes added cost, and more failure points are added. But

Attachments

Because the springs are a constant pressure point in one direction, down...

Will L.

Well-Known Member

Yes constant spring pressure from the two sides plus timing belt pressure.

Then couple that with the way the bearings are made. Rod and main bearings are two separate halves and are actually egg shaped so there is no force where the seams are. But the seam for the cam bearing is crossed over. I hate to think how much I would pay for billet cam bearings to eliminate the issues that happen on that seam. I don’t know if I would pay $500 for a set, but I don’t know if I could stop myself either.

When the luck of the draw hits and the seam goes in at the 12:00 position and the oil holes are proper, they have a better chance of surviving. When I do cam bearings I like to get them at the store so I can open them and inspect them SO CAREFULLY. The slightest nick or scratch in a cam bearing gets instantly rejected. People get picky about rod and main, but most have no idea how much more delicate the cam bearings are. The last time I just slammed in a set, but knew they were coming out in under 100,000 so I went with the best 5 out of only 4 sets. I think the set was $40 or so, but I tipped the parts guy $20 for the headache.

The number one point of oil pressure loss is cam bearings. Of all the 6.2/6.5 I have ripped apart (well over a thousand) maybe 3 rod and 5 main bearings spun. But I have seen over 50 cam bearings spun. Sbc, bbc, sbf, bbf, on and on- all the same. They spin but the engine keeps running with crap oil pressure and shoving metal into the other bearings. I seriously tried doing babbit 3 times before giving up on that. If I was rich and famous, split roller bar bearings on titanium narrow shaft cam- no joke.

Since I’m not rich- Chris will be coating my camshaft amongst other parts, and doing the build up coating on the outside of the cam bearings so I can burnish them to the perfect fit. And that day is getting closer.

And it wouldn’t surprise me to learn they thought about oil level sensor when they made the form for the pan.

Then couple that with the way the bearings are made. Rod and main bearings are two separate halves and are actually egg shaped so there is no force where the seams are. But the seam for the cam bearing is crossed over. I hate to think how much I would pay for billet cam bearings to eliminate the issues that happen on that seam. I don’t know if I would pay $500 for a set, but I don’t know if I could stop myself either.

When the luck of the draw hits and the seam goes in at the 12:00 position and the oil holes are proper, they have a better chance of surviving. When I do cam bearings I like to get them at the store so I can open them and inspect them SO CAREFULLY. The slightest nick or scratch in a cam bearing gets instantly rejected. People get picky about rod and main, but most have no idea how much more delicate the cam bearings are. The last time I just slammed in a set, but knew they were coming out in under 100,000 so I went with the best 5 out of only 4 sets. I think the set was $40 or so, but I tipped the parts guy $20 for the headache.

The number one point of oil pressure loss is cam bearings. Of all the 6.2/6.5 I have ripped apart (well over a thousand) maybe 3 rod and 5 main bearings spun. But I have seen over 50 cam bearings spun. Sbc, bbc, sbf, bbf, on and on- all the same. They spin but the engine keeps running with crap oil pressure and shoving metal into the other bearings. I seriously tried doing babbit 3 times before giving up on that. If I was rich and famous, split roller bar bearings on titanium narrow shaft cam- no joke.

Since I’m not rich- Chris will be coating my camshaft amongst other parts, and doing the build up coating on the outside of the cam bearings so I can burnish them to the perfect fit. And that day is getting closer.

And it wouldn’t surprise me to learn they thought about oil level sensor when they made the form for the pan.

FellowTraveler

Well-Known Member

Exactly, by the way are you doing air pressure application of tungsten yet?Life is full of "what if's" what if frogs had wings....then they wouldn't bump their butt...

The bearing coatings stop dry starts, a pre oiler is like insurance to me when I have so much into a motor and my dually sits for months and only gets cranked when I think about it.. and it's only money...

No, very costly to start up.

I don't think it would harm a thing, fact is I plan to use one, heck if someone only thinks of the "what all could go wrong" part then why would you risk oil cooler lines at all, could they not rupture.... if someone is that worried they should just leave the motor a sealed unit... but then the oil pump shaft could break...

I think the pre oilers are well worth the cost for someone that wants the best possible protection long term ...

I already have some of the parts from these folks, and will get the rest of what I need from them..

Canton Racing Products | Performance Oil Pans, Coolant Tanks, Accusump, Oil Filters...

Our products solve your engines' oil and cooling problems. Improve your engines oil pressure, oil temperature, and coolant system with Canton Racing Products.www.cantonracingproducts.com

Considering GM already made a diesel engine a 'oil sealed unit' on the Duramax with the elimination of the CHEAP Low Bidder Oil Cooler Hoses and relocating the coolant oil cooler on the engine... My word what trouble I have had with those low grade GM oil cooler hoses on a 4.3L TBI V6 (With the HD cooling option) leaking in the 1990's and getting hard from heat on the 6.5TD. Others have had them blow out and take the engine with them including the weak clip design failing. Sadly hoses can and do go wrong on a regular basis. So is it worth the risk and I mean what does the oil accumulator do for you on this engine?

Oil cooler lines "Quality Hoses" isn't the final word. High temperature is. 350 degrees F continuous rating in my experience isn't high enough. We put a 2 quart oil cooler on our 2008 Duramax and had lower rated hoses harden and leak badly.

Some engines like GM's LS2 6.0L V8 aka GTO and Trailblazer SS. Well some MORON(s) at GM allowed the oil pickup to be placed in the front of the oil pan. So you stomp it at the track and loose a rod bearing in 1/4 mile from the oil pump pickup being uncovered. In this situation the accumulator would help. The aftermarket stepped up and showed GM how to build a proper oil pan and rear oil pickup that doesn't have this problem...

Will L.

Well-Known Member

Gm being cheap and barely make it out of warranty plan is the issue.

As to the oil hose for a primer or accumulator- anyone gonna spend a couple hundred dollars on an improvement to extend bearing life generally wont use a cheap hose to do it.

Hmmwvs/ hummers oil cooler hose on the 6.2/6.5 doesn’t use those stupid clips. It is regular fittings and hose like would be on a caterpillar or other yellow iron. Money invested in reliability. And thats how to do any oil system- hydraulic hose, which btw is rated for temps higher than conventional motor oil can withstand. The last hydraulic hose I had made was $30. The heat and pressures one would see in this application, the hose should be replaced early to be on the safe side a say every 50 years.

As to the oil hose for a primer or accumulator- anyone gonna spend a couple hundred dollars on an improvement to extend bearing life generally wont use a cheap hose to do it.

Hmmwvs/ hummers oil cooler hose on the 6.2/6.5 doesn’t use those stupid clips. It is regular fittings and hose like would be on a caterpillar or other yellow iron. Money invested in reliability. And thats how to do any oil system- hydraulic hose, which btw is rated for temps higher than conventional motor oil can withstand. The last hydraulic hose I had made was $30. The heat and pressures one would see in this application, the hose should be replaced early to be on the safe side a say every 50 years.

FellowTraveler

Well-Known Member

SS Braided 8-AN hose with teflon liner is more than suitable for those lines near exhaust or turbine use fire sleeve cover.Gm being cheap and barely make it out of warranty plan is the issue.

As to the oil hose for a primer or accumulator- anyone gonna spend a couple hundred dollars on an improvement to extend bearing life generally wont use a cheap hose to do it.

Hmmwvs/ hummers oil cooler hose on the 6.2/6.5 doesn’t use those stupid clips. It is regular fittings and hose like would be on a caterpillar or other yellow iron. Money invested in reliability. And thats how to do any oil system- hydraulic hose, which btw is rated for temps higher than conventional motor oil can withstand. The last hydraulic hose I had made was $30. The heat and pressures one would see in this application, the hose should be replaced early to be on the safe side a say every 50 years.

That"s exactly what I was intending on using.SS Braided 8-AN hose with teflon liner is more than suitable for those lines near exhaust or turbine use fire sleeve cover.

Will L.

Well-Known Member

Better than an open hose- but I dont see why when you have to go to the Rolls Royce to get more expensive-which is this link. You could literally drag this stuff down the hiway, run over it, have it lay directly on the exh manifold and survive.

Most the AN fittings now are lightweight rather than heavy duty. Wanna save weight, drive a honda. Trucks weigh more and resist failure from weaker parts imo.

Most the AN fittings now are lightweight rather than heavy duty. Wanna save weight, drive a honda. Trucks weigh more and resist failure from weaker parts imo.

FellowTraveler

Well-Known Member

Parker makes some good sh_t I've used it myself however, alloy/steel AN fittings and SS braided hose have an excellent reliability history in cars trucks aircraft and in the marine industry too. Knowing what to select for any given application is critical.Better than an open hose- but I dont see why when you have to go to the Rolls Royce to get more expensive-which is this link. You could literally drag this stuff down the hiway, run over it, have it lay directly on the exh manifold and survive.

Most the AN fittings now are lightweight rather than heavy duty. Wanna save weight, drive a honda. Trucks weigh more and resist failure from weaker parts imo.

Hey guys, I need to ask everyone what their 6.5's oil pressures are at idle? I have all of the parts to do a mock up test run of my pre oiler system with the exception of the pressure switch. I should have it any day now and I figure I'll set it right around idle oil pressure to start out with, so let me know what your idle oil pressures are please.

I am using the switch part number 0166-408 on the following website http://infinityaerospace.com/product/other/pre-oiler-and-back-up-engine-oil-pump/

I am using the switch part number 0166-408 on the following website http://infinityaerospace.com/product/other/pre-oiler-and-back-up-engine-oil-pump/

Last edited:

MrMarty51

Well-Known Member

Hot idle 20. Cold idle over 50.

ak diesel driver

6.5 driver

Hot 30-40 cold 60+

How are you planing to plum it in?

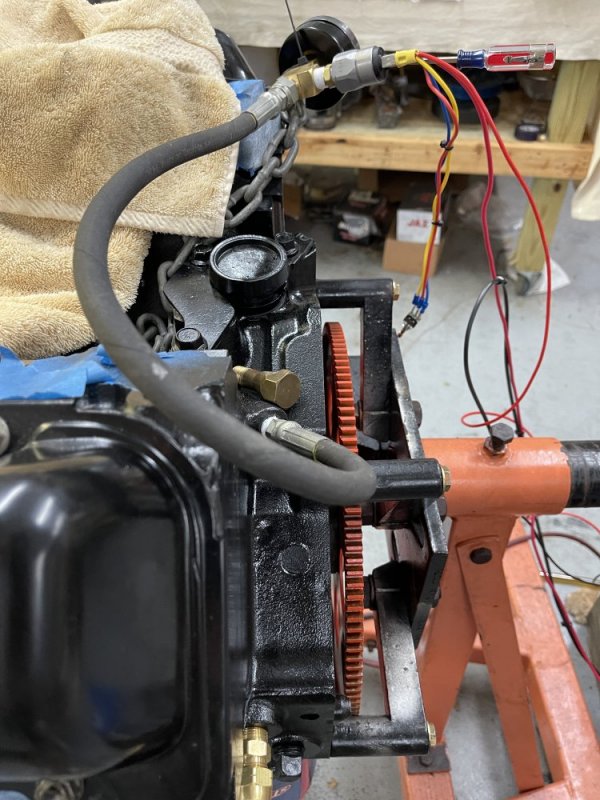

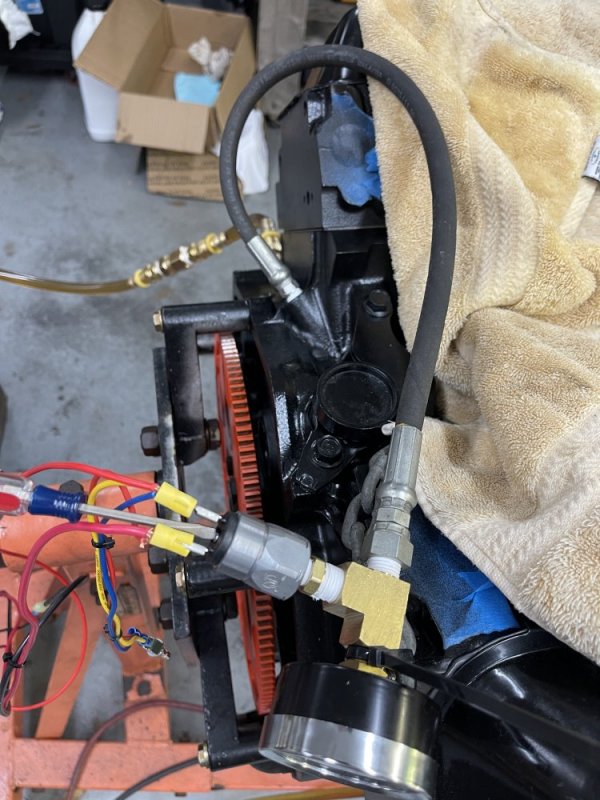

I don't think this hose is going to clear the firewall the way it is and I don't really want to use the OEM brass fitting, so I'm thinking maybe a 1/4 inch NPT 90* will work, we'll see. When I flip the switch to turn the pump on it only takes about 3 seconds to reach 30 lbs so I think I can just wire it to ignition on power with the pressure switch, therefore no need to wire it triggered by the glow plug solenoid. But I'll work out the bug's after the engine and everything is installed in the truck.

Attachments

Last edited:

Will L.

Well-Known Member

Imo put a “T” on the end of ops extension hose for it. That rear port is so close and hard to deal with.