Matt Bachand

Depends on the 6.5

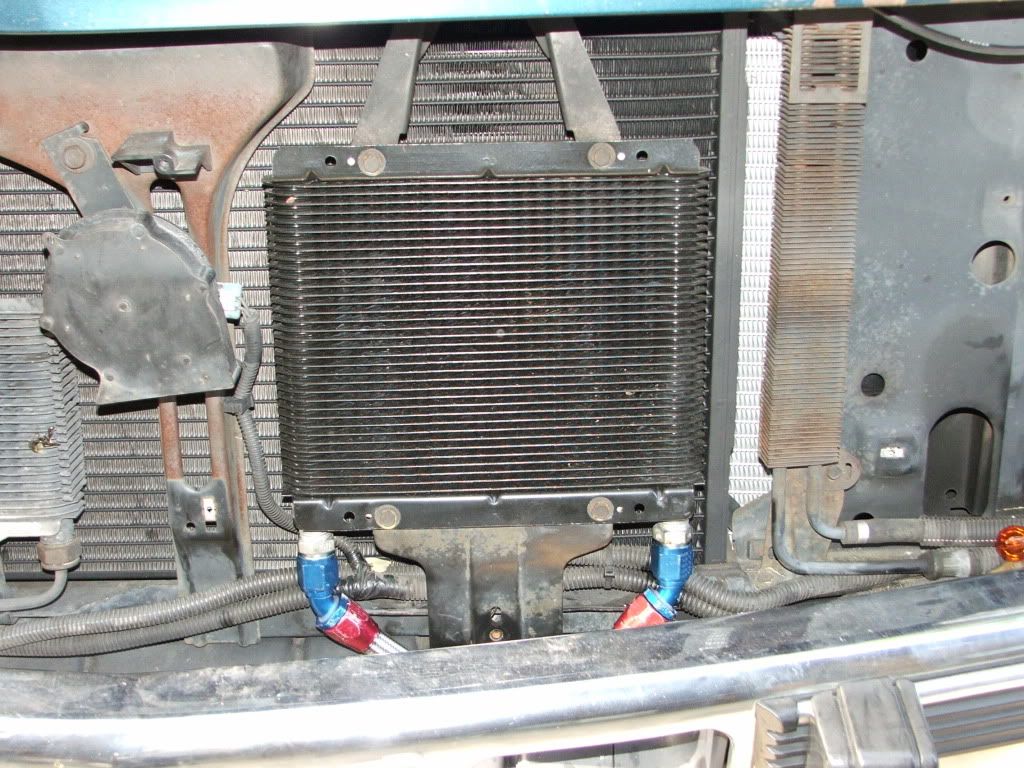

The 45 degree hose ends are a much better way to go than trying to get the 45 degree fittings at the right angle to get the hoses hooked up. I wrecked a cooler trying to get the fitting lined up. Then there is the part of if it's tight enough to not leak if in that position. Are you listening Greg and Leroy?

:thumbsup: