great white

Well-Known Member

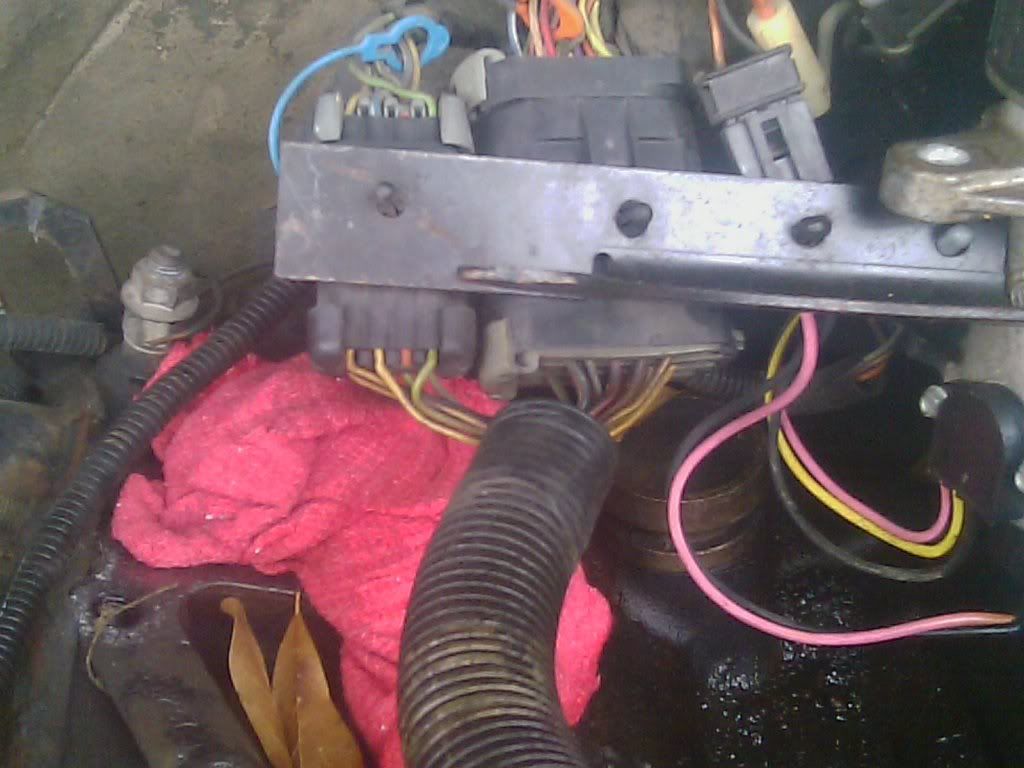

Will I need to replace the intake do y'all think jb weld will hold??

You need to replace it.

JB weld would be pointless in that location.

With a turbo charged engine, you'll be loosing boost if the intake gasket is not "clamped" properly.

You may be able to have it welded if you find a good welder, but aluminum has a tendancy to warp and require machining in a small area with a sealing surface like that.

You could probably buy one off a junker for less than it would cost to repair it.