red

Being a lake bum in Texas

Yep that was the problem I ran into with the oil pan clearance.

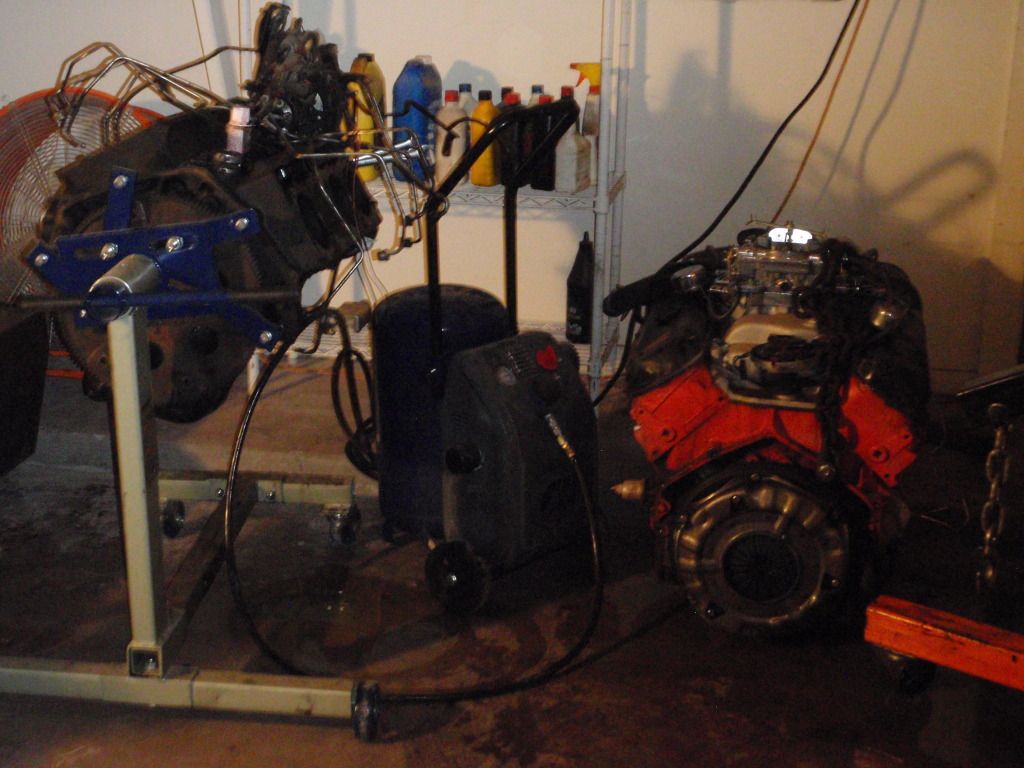

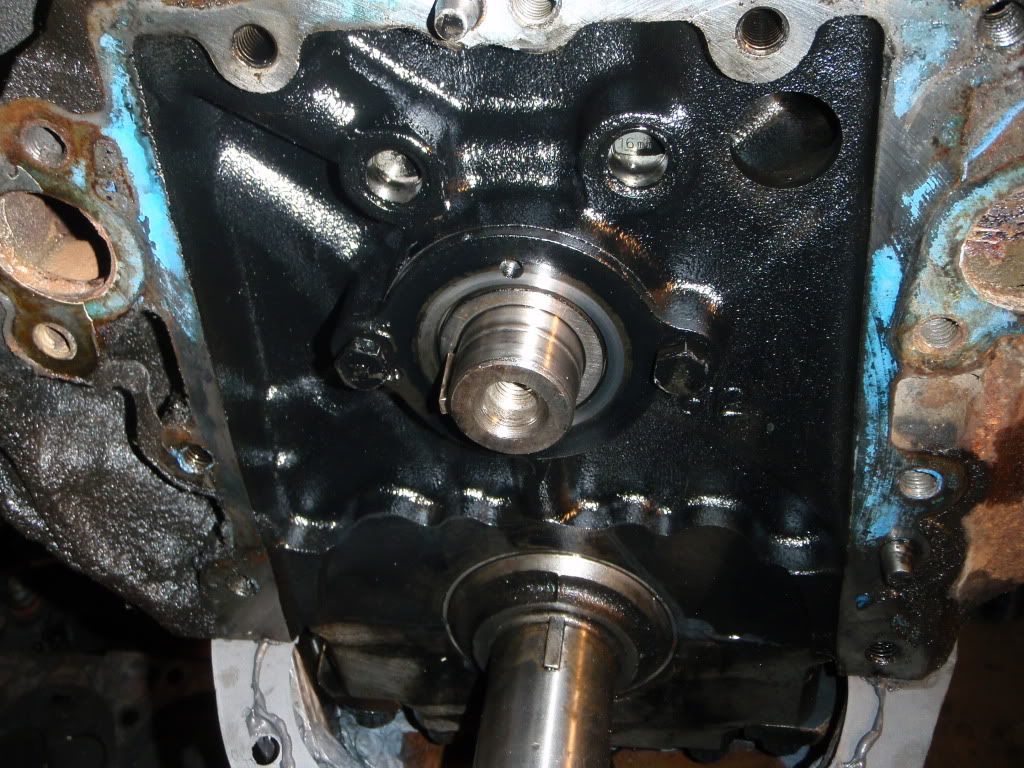

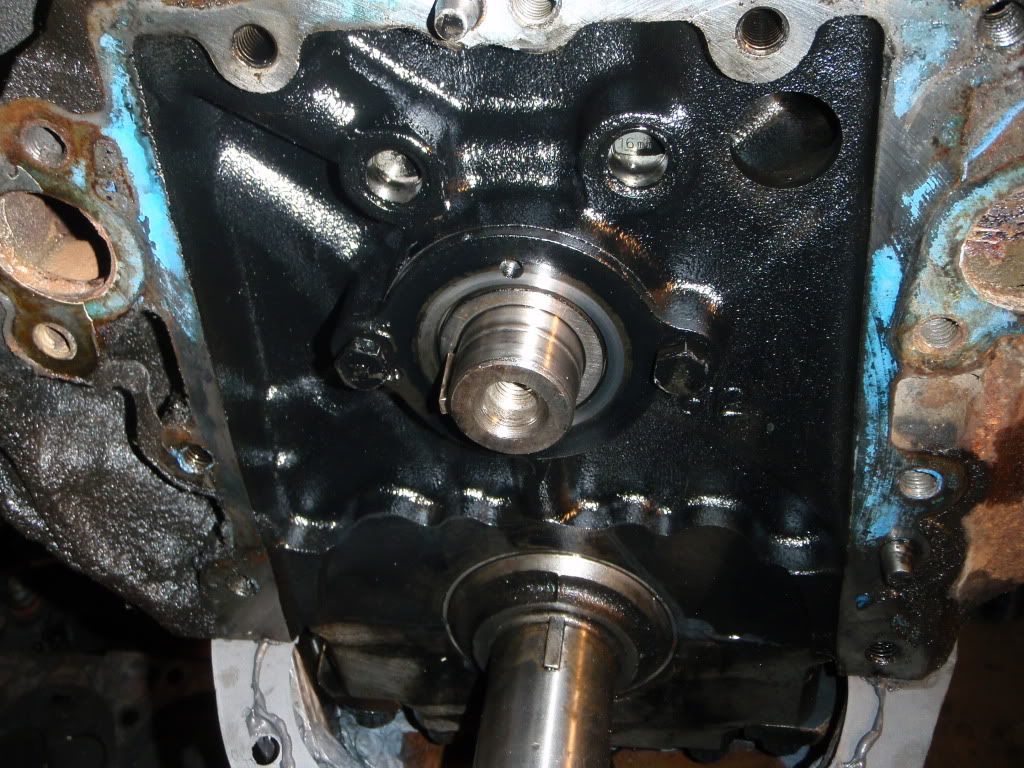

Well bottom end of the motor is now assembled, hopefully it wont have to be touched for a very, very long time.

With that stage complete Its time to move onto the cam!

Since the pushrods and the timing chain have already been removed for awhile there isn't much left to remove to get the stock cam out.

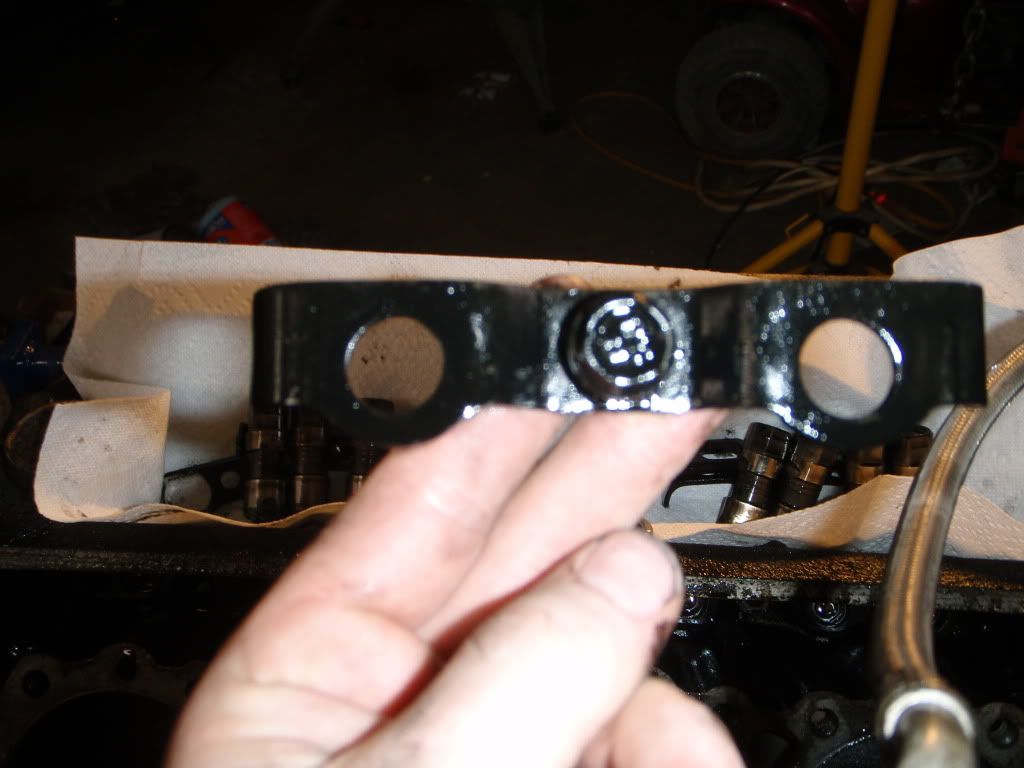

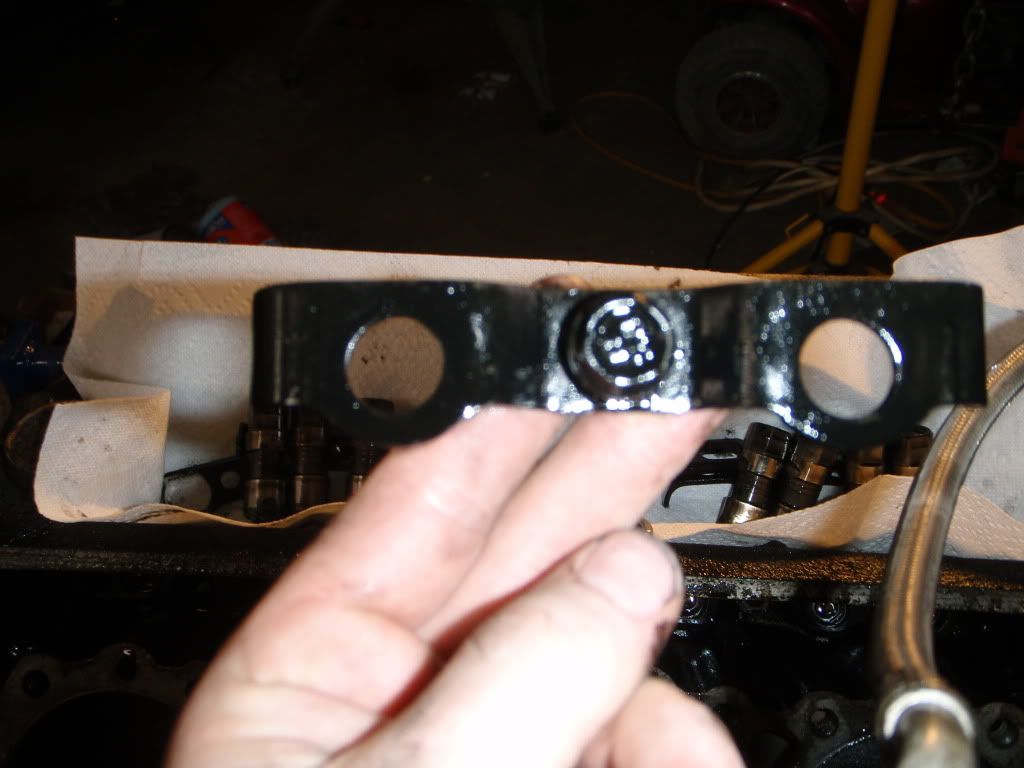

Unbolt these plates that hold the lifter assemblies in (4)

Then reach in and lift off the rest of the retaining plates

Which leaves you with the lifters (16)

Some of the lifters were coming out by hand, others needed a little bit better grip (still oil coated)

With the lifters taken care of went to the back of the intake valley and removed you

Then went to the front and removed the retaining plate (2 bolts)

Need to get myself some assembly lube then the new cam will go in. Then to decide on closing up the front or the top of the motor next.

Well bottom end of the motor is now assembled, hopefully it wont have to be touched for a very, very long time.

With that stage complete Its time to move onto the cam!

Since the pushrods and the timing chain have already been removed for awhile there isn't much left to remove to get the stock cam out.

Unbolt these plates that hold the lifter assemblies in (4)

Then reach in and lift off the rest of the retaining plates

Which leaves you with the lifters (16)

Some of the lifters were coming out by hand, others needed a little bit better grip (still oil coated)

With the lifters taken care of went to the back of the intake valley and removed you

Then went to the front and removed the retaining plate (2 bolts)

Need to get myself some assembly lube then the new cam will go in. Then to decide on closing up the front or the top of the motor next.