Scott_2255

Active Member

- Messages

- 33

- Reaction score

- 101

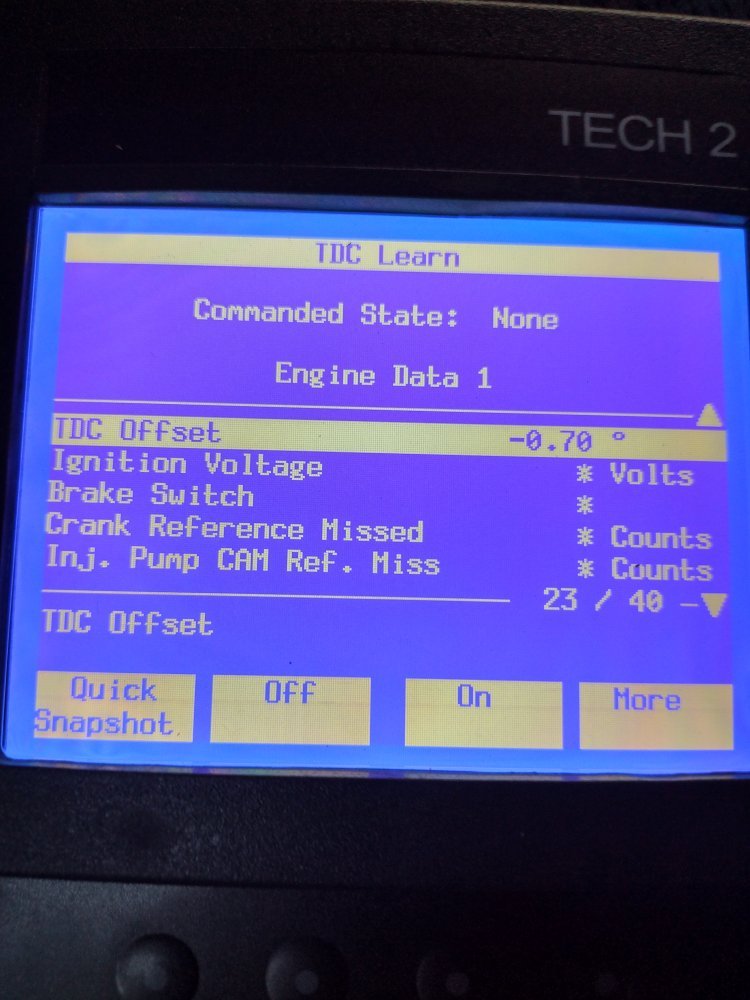

Hello, I am trying to resolve a problem with my injection pump on my 6.5. The engine is brand new (rebuilt) and so is the injection pump. I cannot get the truck to start easily. It has lots of white and grey smoke have to crank it a lot. I am getting the injection pump timing error P0216. I have a tech II and can read the actual timing, desired timing, and offset. The offset is -.70, the desired timing is 15.8 Deg and the actual timing is always 3.5 deg. (See attached pics)

I thought it was a bad stepper motor, checked wiring from PCM to stepper with stepper connected and it was within tolerance. Decided to buy a new stepper anyway as the PCM was sending a signal yet the timing would never change.. I installed the new stepper and nothing changed. I shut off the engine and connected the old stepper up to the harness and re-started the truck. With the Tech II I commanded a Set Time command and the stepper fully extended, when I turned the Set time back to off the stepper fully retracted.

This means to me that the stepper and PCM are ok and functioning. My only other guess is I have the base timing way off, meaning that I have the engine and fuel pump and crank physical timing off by a LOT. Does this seem like the issue? I am hesitant to re time by removing the injection pump, and rotating the crank as I think I could make it worse. I also attached a pic of the engine prior to installing the water pump. Any ideas?

I thought it was a bad stepper motor, checked wiring from PCM to stepper with stepper connected and it was within tolerance. Decided to buy a new stepper anyway as the PCM was sending a signal yet the timing would never change.. I installed the new stepper and nothing changed. I shut off the engine and connected the old stepper up to the harness and re-started the truck. With the Tech II I commanded a Set Time command and the stepper fully extended, when I turned the Set time back to off the stepper fully retracted.

This means to me that the stepper and PCM are ok and functioning. My only other guess is I have the base timing way off, meaning that I have the engine and fuel pump and crank physical timing off by a LOT. Does this seem like the issue? I am hesitant to re time by removing the injection pump, and rotating the crank as I think I could make it worse. I also attached a pic of the engine prior to installing the water pump. Any ideas?