93detroit

Well-Known Member

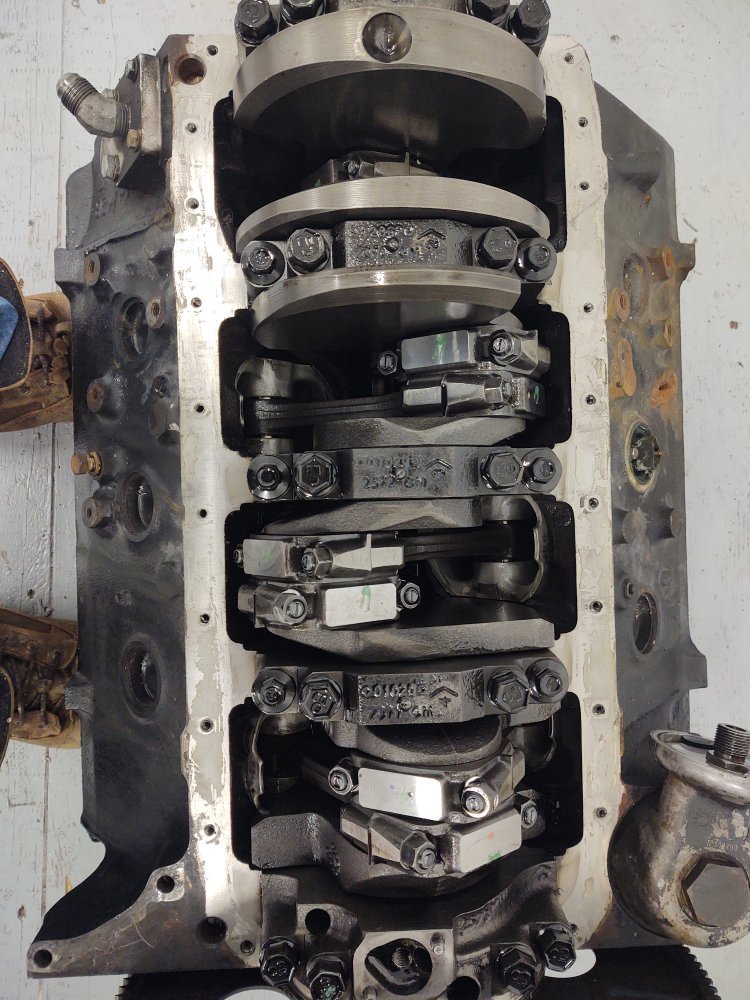

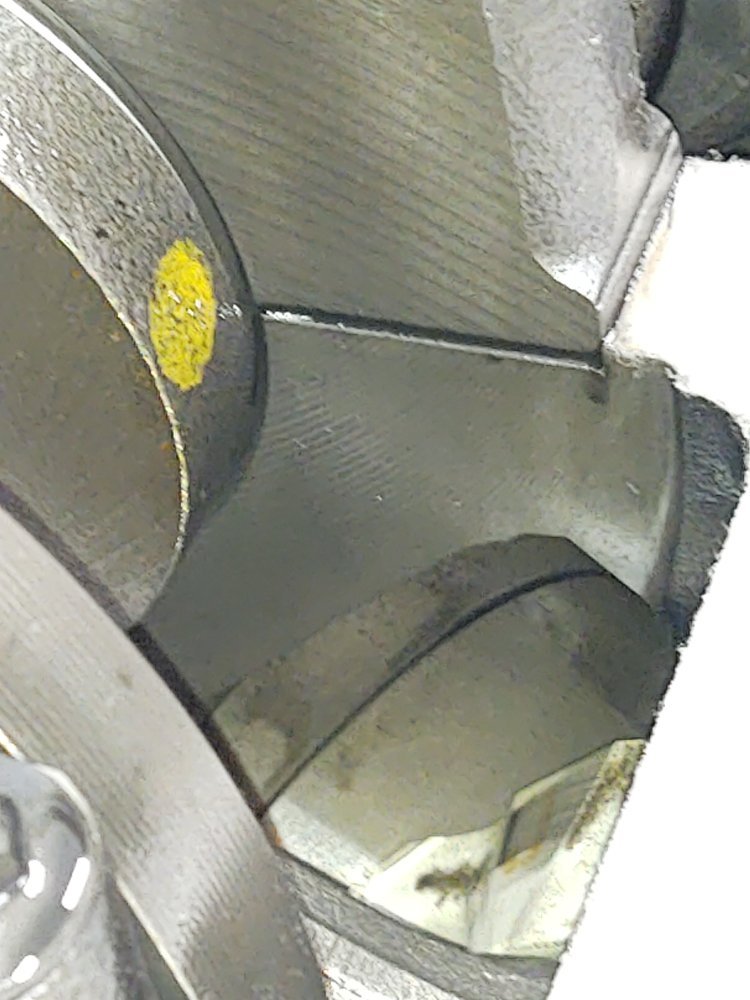

Say a prayer for her fellas. Everything looks great so far. Need to get the crank out to really look at the webbing. Hopefully cleaning up the decks and a light hone in the cylinders. If the block is good, HV oil pump, studs, heads and 18:1 pistons (ceramic coated).