turbovanman

I has boost, :O)

OK, so I've been wanting to do this forever and finally bit the bullet and got it done. I honestly thought it would take me 4-6 hours but was I wrong, I think after it was all said and done, I am into it for 22 hours or so, sigh and still have some things to tweak. Turbo is an HX35W.

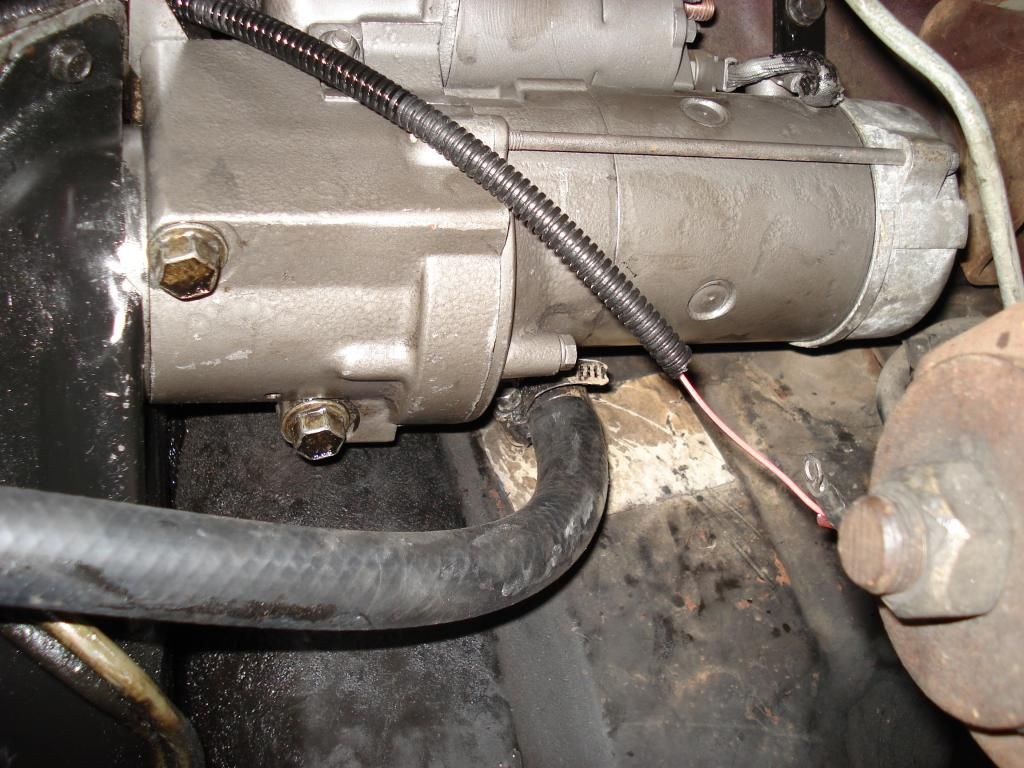

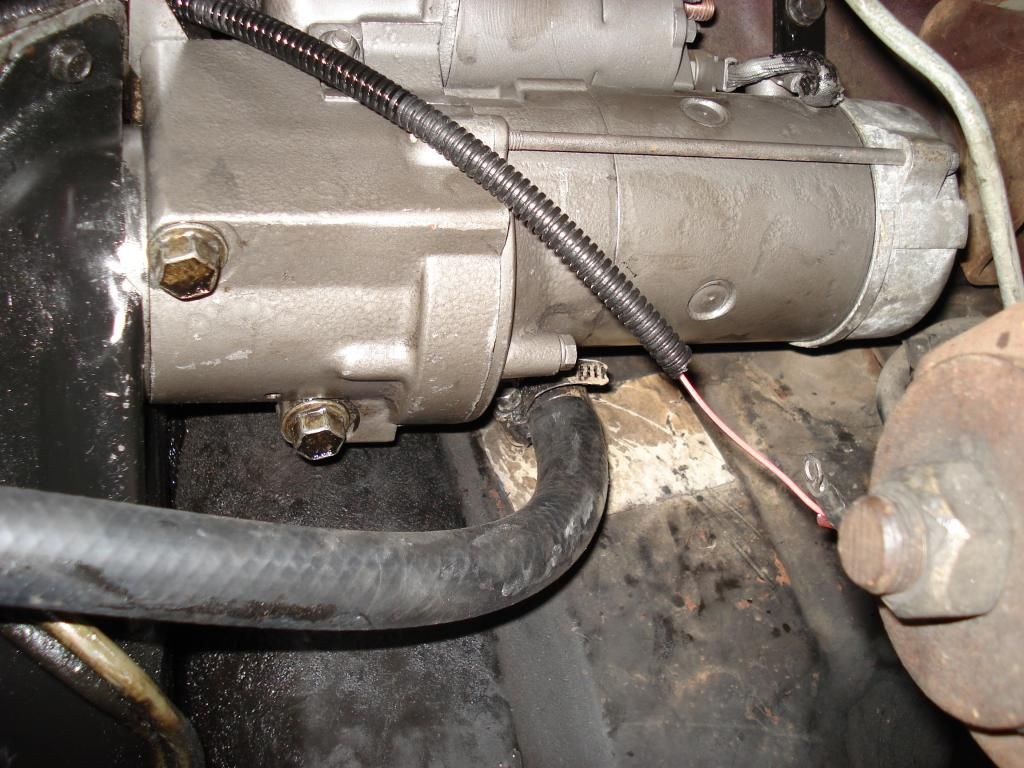

I redid my scavenge pump lines 2-3 times, I had originally thought about using the oil cap but didn't realize it was a vent, so welded a fitting to the oil fill and that ended up blowing oil out of the CDR. I also found my used pump was no good but luckily had a Surflo pump kicking around so got it going but ordered a new, better model today. I finally put a fitting in behind the starter into the oil pan. I was going to use a valve cover but punched a hole in the wrong spot and after seeing how much oil comes out at idle, I decided that was too much oil to put there. You will notice I used heater hose for the return lines, I will be changing it to proper rated hose soon, as well as redoing the drain back elbow.

Don't mind the exhaust, I was tired and should have gone home, its an abortion but doing to replace the muffler with something smaller.

Boost control is done by knife edging the TS housing, opening up the wastegate hole and using an adjustable boost elbow off Ebay.

Piping was from CX Racing, my friend welded it up for me and made the hat, 3" aluminum. I have to redo the upper pipe, its rubbing on the dog house and making it vibrate, Turbo CDR is plumbed into the intake hose.

Air intake plumbing is a dryer vent relocation kit I bought years ago, and the filter is an AEM Dryflow, 4".

Mounted the turbo at the end of the collector using an OBX T3 adapter and used a stock exhaust hanger with rubber mounts to support the turbo.

I have a rear main leak, sigh and the trans tail shaft leaks, all the other oil was from running it and the CDR spitting it out all over the engine.

Think I have it covered, so any questions, just ask.

I have to check it over tonight as there is a lot of oil underneath the truck,

Driving wise, night and day over n/a, around town 3 psi right off idle, 5 psi on the highway and I hit 12 psi easily, I don't have an EGT gauge yet so taking it easy and haven't gone passed 1/2 throttle. The engine is smoother and quieter, and hills I had to work at now are cake, can even use LU all the time. I only want to run 10 psi or so as I don't want to be adding studs and doing the head gaskets.

So after driving it and checking it out tonight, turns out the scavenge pump isn't doing its job, should have bought new, and I have a leaking head gasket, which is a blessing as I was planning a long trip in a few weeks and if I hadn't turbocharged it, it would have blown on me then, :mad2:

I redid my scavenge pump lines 2-3 times, I had originally thought about using the oil cap but didn't realize it was a vent, so welded a fitting to the oil fill and that ended up blowing oil out of the CDR. I also found my used pump was no good but luckily had a Surflo pump kicking around so got it going but ordered a new, better model today. I finally put a fitting in behind the starter into the oil pan. I was going to use a valve cover but punched a hole in the wrong spot and after seeing how much oil comes out at idle, I decided that was too much oil to put there. You will notice I used heater hose for the return lines, I will be changing it to proper rated hose soon, as well as redoing the drain back elbow.

Don't mind the exhaust, I was tired and should have gone home, its an abortion but doing to replace the muffler with something smaller.

Boost control is done by knife edging the TS housing, opening up the wastegate hole and using an adjustable boost elbow off Ebay.

Piping was from CX Racing, my friend welded it up for me and made the hat, 3" aluminum. I have to redo the upper pipe, its rubbing on the dog house and making it vibrate, Turbo CDR is plumbed into the intake hose.

Air intake plumbing is a dryer vent relocation kit I bought years ago, and the filter is an AEM Dryflow, 4".

Mounted the turbo at the end of the collector using an OBX T3 adapter and used a stock exhaust hanger with rubber mounts to support the turbo.

I have a rear main leak, sigh and the trans tail shaft leaks, all the other oil was from running it and the CDR spitting it out all over the engine.

Think I have it covered, so any questions, just ask.

I have to check it over tonight as there is a lot of oil underneath the truck,

Driving wise, night and day over n/a, around town 3 psi right off idle, 5 psi on the highway and I hit 12 psi easily, I don't have an EGT gauge yet so taking it easy and haven't gone passed 1/2 throttle. The engine is smoother and quieter, and hills I had to work at now are cake, can even use LU all the time. I only want to run 10 psi or so as I don't want to be adding studs and doing the head gaskets.

So after driving it and checking it out tonight, turns out the scavenge pump isn't doing its job, should have bought new, and I have a leaking head gasket, which is a blessing as I was planning a long trip in a few weeks and if I hadn't turbocharged it, it would have blown on me then, :mad2: