nycxjeremyy

Well-Known Member

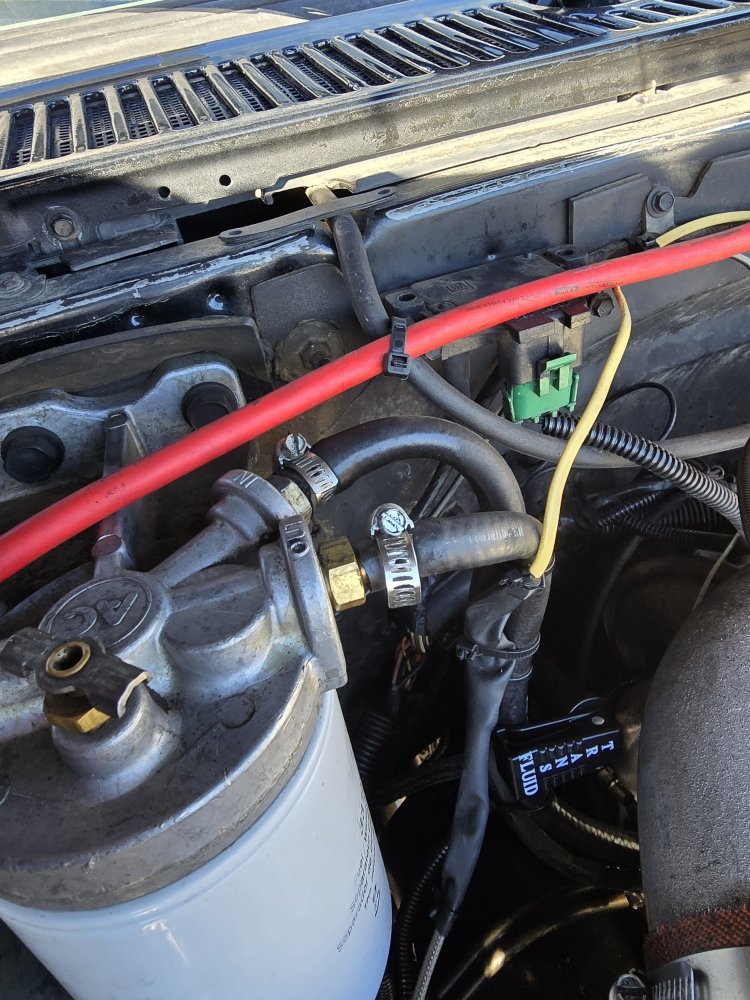

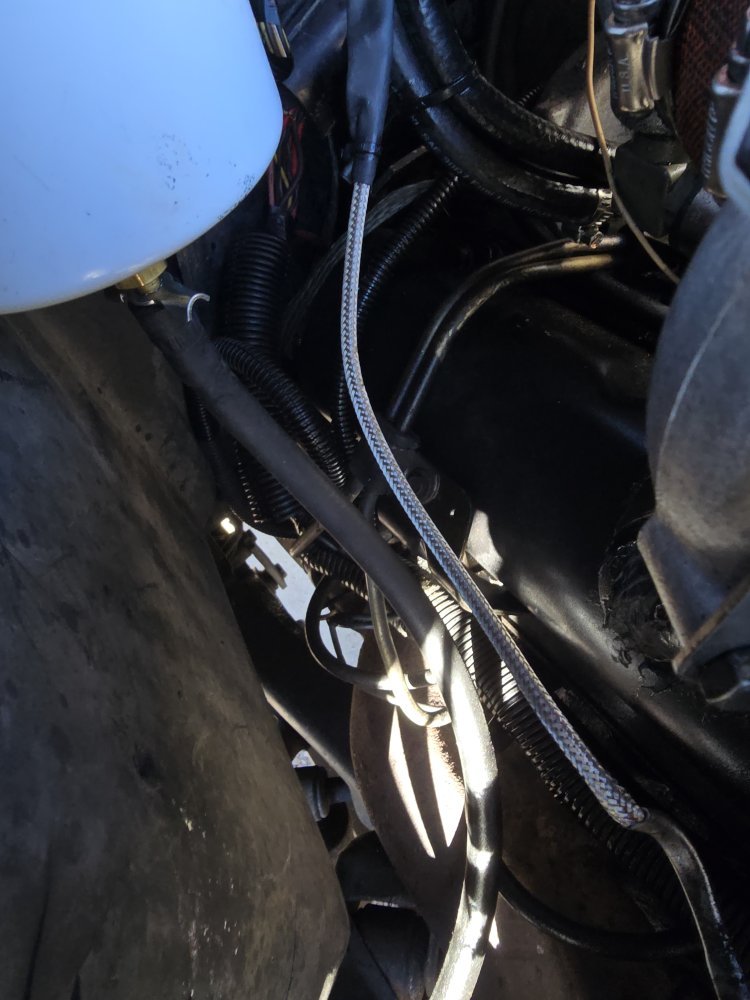

Copy sir, I'll clean/degrease it and see what I find down thereHoly cow…

That differential is probably really low on oil.

The input seal is what is leaking- you have to have the rear end fully set up for replacing that.

Degreaser- clean it all off to start. Remove fill plug & top it off - keep checking it VERY OFTEN until you can learn it all & buy the tools to diy or take it to a shop.

Some people learn it easy and do fine- for others it seems to be rocket surgery.

Imo- again age of truck- you might open it up and find way more than just seal needs replacing. My thought it when doing input seal to do the axle seals at same time. Replace any questionable bearings. Get it all new condition again then you can ignore it for the next couple hundred thousand miles.

YouTube videos get you a decent understanding of the task.