Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome to The Truck Stop! We see you haven't REGISTERED yet.

Your truck knowledge is missing!

- Registration is FREE , all we need is your birthday and email. (We don't share ANY data with ANYONE)

- We have tons of knowledge here for your diesel truck!

- Post your own topics and reply to existing threads to help others out!

- NO ADS! The site is fully functional and ad free!

Problems registering? Click here to contact us!

Already registered, but need a PASSWORD RESET? CLICK HERE TO RESET YOUR PASSWORD!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Crossover donut gasket.

- Thread starter Lawdawg#1

- Start date

Wreckinball67

Well-Known Member

- Messages

- 125

- Reaction score

- 281

Give it a go...it might be that the new was is "new and improved". Keep us updated...

SnowDrift

Ultra Conservative. ULTRA!

The metal ring you're referring to slides up into the manifold and will hold it in place when you put your crossover back on. Your old ones are likely still stuck up in there.

Will L.

Well-Known Member

SnowDrift

Ultra Conservative. ULTRA!

I went through the same thing a week or so ago before coating my manifolds. The sleeve was still in them, but I knew they were not permanent. I used a chisel and knocked off the donut, but the sleeve remained. Logically, it only made sense that it had to come out because the manifolds are cast and the sleeve is not

Paveltolz

Доверяй, но проверяй

This right here SnowDrift, and your previous post #4.I went through the same thing a week or so ago before coating my manifolds. The sleeve was still in them, but I knew they were not permanent. I used a chisel and knocked off the donut, but the sleeve remained. Logically, it only made sense that it had to come out because the manifolds are cast and the sleeve is not

LawDawg#1

Years ago I was changing out things every couple of years. With the frequent changes I was doing, even after a short a time, sometimes it would come out in one piece. Sometimes not.

The first time, like you, was a learning experience.

I got the old donut off with I don’t remember what (probably a hammer and HD putty knife or screw driver), the sleeve stayed behind. Looked to me like it belonged there after 150k miles. Call it corrosion, low temp weld, heat cycles or all the above. Regardless, the old ring on the new donut was ‘getting in the way’ of reassembling things. Ruined a donut (which is why I got a spare still laying around). After asking the same questions on the forum, I got it out after breaking the ‘seal’ between manifold and the ring with a screwdriver and hammer. Once the seal was broke, it was obvious it wasn’t part of the manifold and pliers got it out after that.

Hope these photos help you out.

New gasket/donut

I just checked a manifold on the shelf, old donut still in place from strip yard.

Just for fun this morning, I tried removing it with putty knife and mallet and, as expected, the sleeve remained behind. Looks like it belongs there though.

Gave it a couple of whangs with mallet and chisel on two sides to break the corrosion bond

Pried it out with small screw driver…easy peeasy.

Yes, for the observant out there, the next challenge will be to get that sheared off / rusted in bolt out. Done that before too. Last time it involved Helicoil.

SnowDrift

Ultra Conservative. ULTRA!

I used channel locks and just smashed the sleeve down - it came right out, but I doubt there would be room to do that if still in the chassis.

jrsavoie

Recruit

Maybe a pair of the longer curved jaw vice grips. About my most used vice grips anymore.I used channel locks and just smashed the sleeve down - it came right out, but I doubt there would be room to do that if still in the chassis.

As an Amazon Associate we earn from qualifying purchases.

Big T

Well-Known Member

So I’ve been f’n wrong all along!

Wow thanks for the replies everyone! Much appreciated. I will use an air chisel to try and hammer it out. The pictures really helped because I thought it slipped into a channel of some sort. I can cave it in on itself and get it out with channel locks or vise grips. Thanks again!

Already did two broken bolts. Drilling them out and tapping threads. Used studs instead of bolts.Wow thanks for the replies everyone! Much appreciated. I will use an air chisel to try and hammer it out. The pictures really helped because I thought it slipped into a channel of some sort. I can cave it in on itself and get it out with channel locks or vise grips. Thanks again!

dbrannon79

I'm getting there!

I got lucky with the broken bolts on mine. I got them on the first attempt. ground them flat with the manifold and then used a center punch marking the bolt and drilled though with a small bit. went slightly larger and larger and ended with a 3/8" bit. it left just enough meat to run the metric tap into the threads cleaning them out and were still salvageable to re-use without needing to stud them or use a nut on the back side.

be sure to use some extreme heat anti-seize going back in. not sure where to buy it, but at work they keep an anti-seize that is resistant up to 1800 or so degrees. working in a steel mill they use that stuff on everything!!

be sure to use some extreme heat anti-seize going back in. not sure where to buy it, but at work they keep an anti-seize that is resistant up to 1800 or so degrees. working in a steel mill they use that stuff on everything!!

Big T

Well-Known Member

I just drilled them out and used bolts in place of studs, which has worked for many years.I got lucky with the broken bolts on mine. I got them on the first attempt. ground them flat with the manifold and then used a center punch marking the bolt and drilled though with a small bit. went slightly larger and larger and ended with a 3/8" bit. it left just enough meat to run the metric tap into the threads cleaning them out and were still salvageable to re-use without needing to stud them or use a nut on the back side.

be sure to use some extreme heat anti-seize going back in. not sure where to buy it, but at work they keep an anti-seize that is resistant up to 1800 or so degrees. working in a steel mill they use that stuff on everything!!

jrsavoie

Recruit

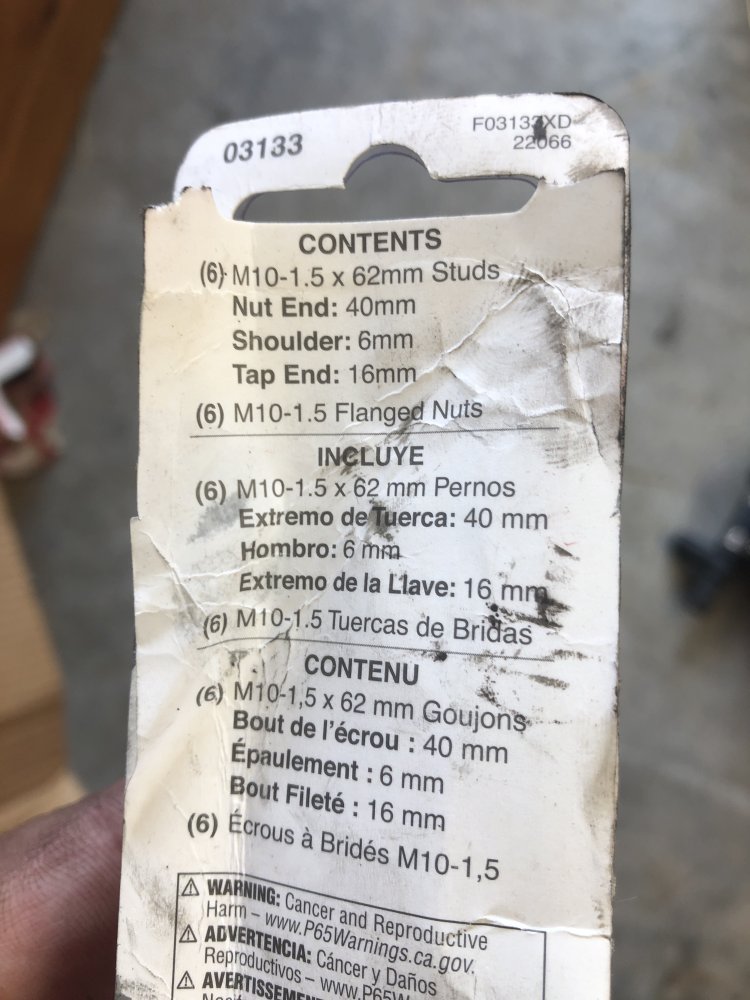

What's the thread pitch and size?Already did two broken bolts. Drilling them out and tapping threads. Used studs instead of bolts.

I thought it was 3/8-16

dbrannon79

I'm getting there!

it's a 10mm 1.5 thread iirc

Paveltolz

Доверяй, но проверяй

Big T

Well-Known Member

I thought it the daughter of Chief No Looking Horse?Your recollection is correct.

I used these studs on the truck. Got them at O’Reilly or AutoZone.

View attachment 81843

Was going to use them on the Suburban but…OBC or Overcome by Jeep Patriot.

M10-1.5What's the thread pitch and size?

I thought it was 3/8-16