88gmctruck

02GMCtruck

I haven't full decided what i'm doing with the grille & lighting. Planning on a GMC grille (probably junkyard). Headlights wither TYC or find adjusters to run my quad bosch H4 lights.....

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Correct.the Hays disc appears to have quite abit more friction material, as in surface area. is that so?

That is what i'm thinking then again this is the OE replacement which hold up fine too. I'm thinking I'll just run this stock one. I can pull the transmission in about 2 hours anyway.Pretty dramatic difference in clutches. I've always bought the best clutch setup I could get at the time as long as I had to go that far.

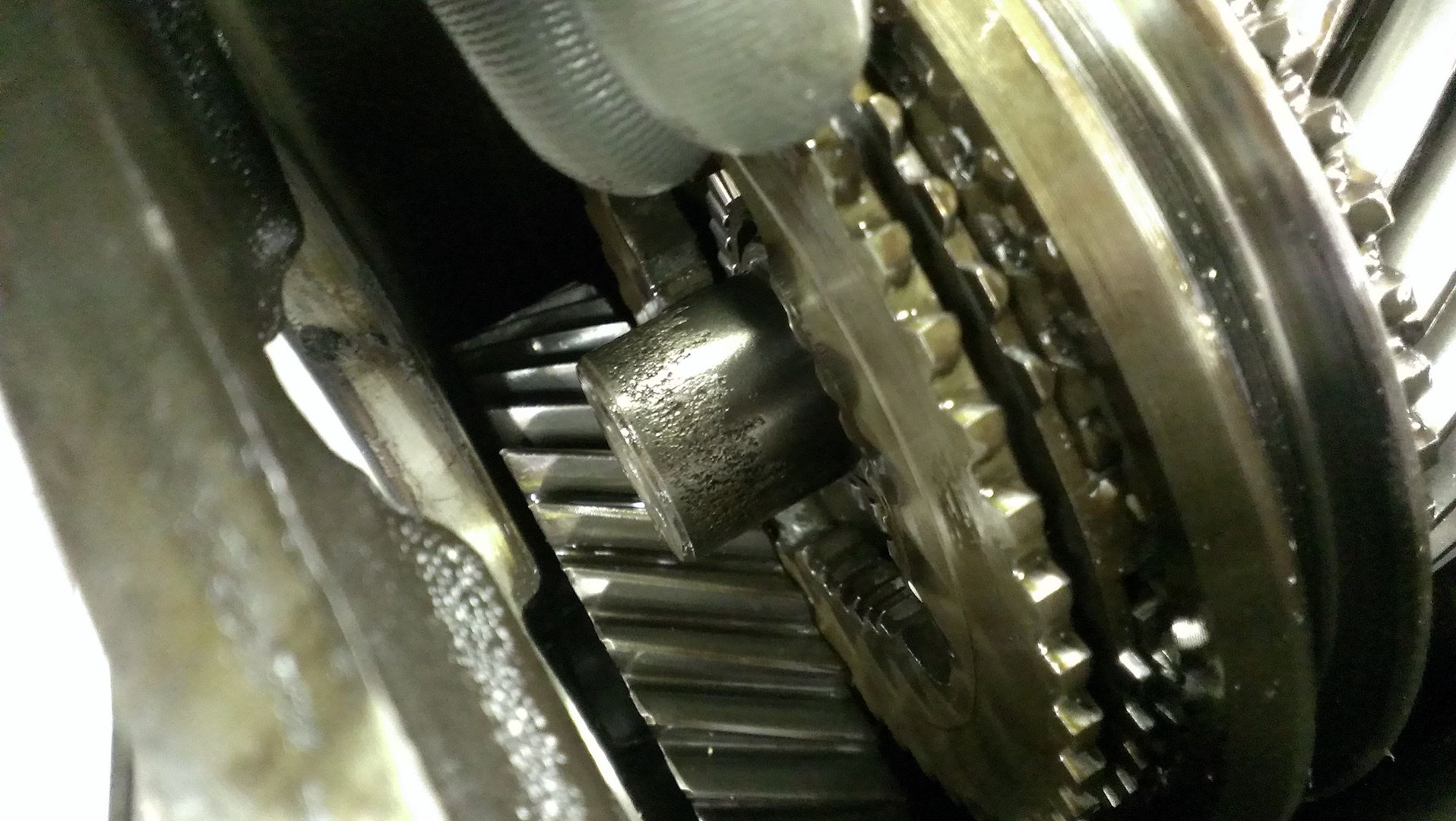

Looks like the wrong oil was used. Many think syncromesh is compatible, but it is not. You need to run a GL-4 of an 80W90 viscosity and is a full synthetic with modifiers for cold performance.

Well I know this truck had a camper on it, by the looks of it for a good part of its life. I'm thinking it was probably a combination of age, heavy loads, and incorrect fluid.Nice post Dave. That trans saw some serious abuse at some point or was run dry/hot. Pilot bearings are a big culprit for a failed high gear. Seen it my share of times back when most trucks were manual.

The ONLY fluid that should be in a NV4500 is the GM/Chrysler Castrol Syntorque. It is a GL-4 but is 75W90 viscosity full synthetic. It's a dealer only item, other than a few transmission places that have bought large quantities of it. I've ran the amsoil rated equivalent and it doesn't perform near as well as the Castrol stuff does. From what I've been told and have read, the factory stuff is a specific blend that off the shelf fluids do not have to protect the syncros.Looks like the wrong oil was used. Many think syncromesh is compatible, but it is not. You need to run a GL-4 of an 80W90 viscosity and is a full synthetic with modifiers for cold performance.

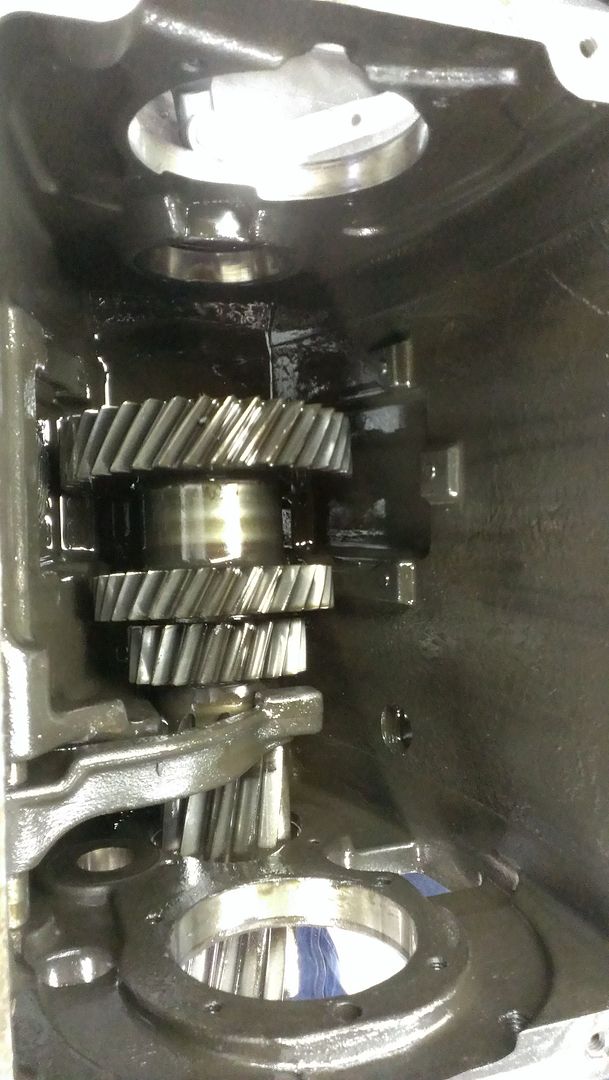

My countershaft and rear main bearing looked fine, but the wear on the input and it's bearings is what did it in.That's alot of the same wear that was on my 94, the main shaft was ok but the bearings were crap and you could see discoloration from heat, pitting was next. The local machine shop polished it up and it looked alot better.

Source Unknown

Chevy and Dodge input shafts are different to my knowledge.Are you using the Dodge input shaft? IIRC its a direct replacment and is stronger. Not sure, but might be a good mod. Seem to remember that being a common mod when doing a Cummins convertion.

Are you using the Dodge input shaft? IIRC its a direct replacment and is stronger. Not sure, but might be a good mod. Seem to remember that being a common mod when doing a Cummins convertion.

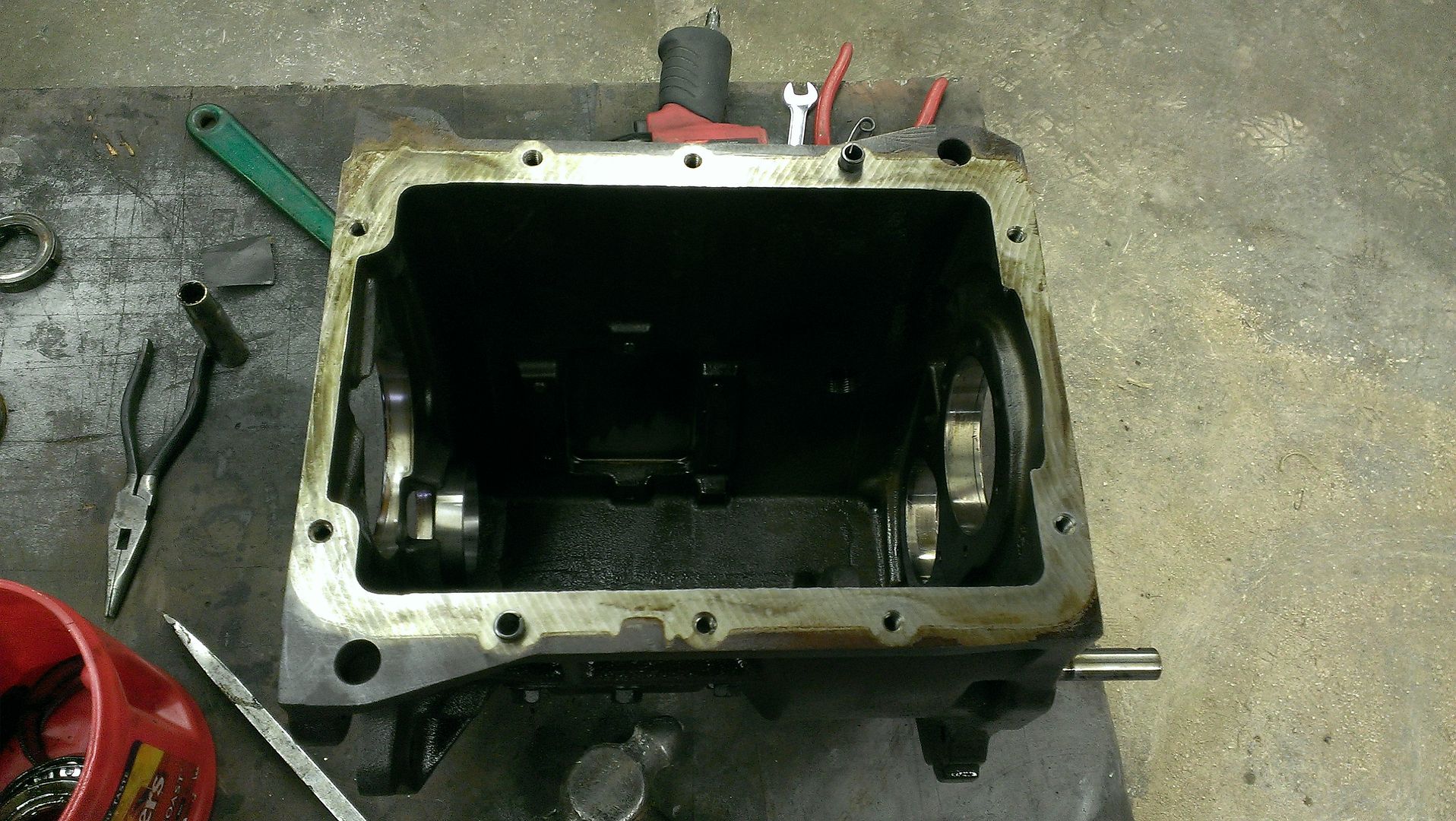

Oh yeah, this wouldn't be possible without this tool set....

Chevy and Dodge input shafts are different to my knowledge.