Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome to The Truck Stop! We see you haven't REGISTERED yet.

Your truck knowledge is missing!

- Registration is FREE , all we need is your birthday and email. (We don't share ANY data with ANYONE)

- We have tons of knowledge here for your diesel truck!

- Post your own topics and reply to existing threads to help others out!

- NO ADS! The site is fully functional and ad free!

Problems registering? Click here to contact us!

Already registered, but need a PASSWORD RESET? CLICK HERE TO RESET YOUR PASSWORD!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

6.5 non turbo diesel 4L80E chevy p30 StepVan

- Thread starter Brenttt

- Start date

TPS was tight reading 2.08 v at o% 4.60 v at 100% adjusted it to 0.5v at 0% but only goes to 4.08 v at 100% engine still winding out before shiftIn 1993 the input speed sensor and output speed sensor on the driver side are the same plug. IDK about newer years. These are two wire connectors. Their wiring off the transmission going into the harness bundle has insulation that fell off right at the bundle on a few pickups I have run across including a 454 powered rig. Bare copper shorts the sensor reading out. This is NOT the main transmission connector. You may also look at it for possible oil leaks at/in the main trans connector as oil is an insulator.

As mentioned the TPS looks like it was put on loose and worked itself to the end of the adjustment.

MrMarty51

Well-Known Member

I dont know much about these types a situations. I dont know if there is a + or - factor that if it is so close it would be all right.TPS was tight reading 2.08 v at o% 4.60 v at 100% adjusted it to 0.5v at 0% but only goes to 4.08 v at 100% engine still winding out before shift

See if we can call in the resident Main trouble shooter.

@THEFERMANATOR

HELLLLP ! ! ! !

I changed the sensors on the side of the trans

So you eliminated one problem with the TPS out of adjustment.

Why did you replace the sensors on the side of the trans?

I assume you have cleaned the grounds, but, if you haven't: Look for the ECM ground generally by the trans dipstick on the passenger side engine head. Take it apart and clean it. Battery cables grounds and positive need to be in good shape. A stiff cable with corrosion leaking out of it is a problem. Load test the battery. Any electrical brownouts can cause a ECM to screw up.

You have two choices on how to fix this:

Dumb Luck:

Inspecting the wiring and sensors I mentioned on the last page. Including swapping the plugs on the two speed sensors you swapped out just in case they are backwards.

Renting someone with a Tech 2 and their experience using it:

It will tell them why the engine is revving up before shifting. Simply one of the sensors is not working, hooked up wrong, or shorted. Worst case the ECM has died of old age, but, they are dead last to assume has failed.

It is a. Y engineWhat's the engine code on the vin ?

Y code is a bare bones DB2 non turbo engine . Reason I asked was sometimes the P vans are behind the trucks in tech . You really need to get a scanner on there , as others have stated . Are all the wires OK , especially the engine speed sensor ?

Jaryd

Extremely Deplorable

I have a 1996 p30 Stepvan with a 4l80e transmission. The engine winds out close to redline before it shifts into 2 3 and 4 gear what could be the cause of this ? The transmission does not slip at all and works fine otherwise

I have a set of factory service manuals for this rig if you are interested

Grisley1958

Well-Known Member

- Messages

- 202

- Reaction score

- 573

I just happened to pop on to this thread, but IIRC the P30 vans were mechanical injection non turbo and if they were automatic transmission there was a stand alone controller under the seat to control the 4L80E. That controller was desirable if you were looking to go from DB4 to DB2 injection and be able to properly control the transmission. I would start there and look at all the connections and ground wires. You shouldn't have a corrosion issue down there like we do up here, but you never know.

MrMarty51

Well-Known Member

If I ever get to an auto salvage lot I will see if they have any of these vans.I just happened to pop on to this thread, but IIRC the P30 vans were mechanical injection non turbo and if they were automatic transmission there was a stand alone controller under the seat to control the 4L80E. That controller was desirable if you were looking to go from DB4 to DB2 injection and be able to properly control the transmission. I would start there and look at all the connections and ground wires. You shouldn't have a corrosion issue down there like we do up here, but you never know.

I think that most all vans had an auto transmission from the factory.

Grisley1958

Well-Known Member

- Messages

- 202

- Reaction score

- 573

I bought one a few years back because it had the 6.5 mechanical but it had the NV4500. I got a great deal on it because the place that had it owned a tiltbed that had a 6.5 with DB4 pump that kept quitting whenever they took it out on a call. I diagnosed it for them and set them up with a remote PMD. It never had an issue after that. They made me a deal I couldn't refuse on the P30. I wound up selling the engine to a friend that had a bad 6.5 in his suburban. Scraped the truck but kept the transmission.

I’ll have to find this controller it’s definitely not under the seat as it’s a pedestal seat this is a old snap on truckI just happened to pop on to this thread, but IIRC the P30 vans were mechanical injection non turbo and if they were automatic transmission there was a stand alone controller under the seat to control the 4L80E. That controller was desirable if you were looking to go from DB4 to DB2 injection and be able to properly control the transmission. I would start there and look at all the connections and ground wires. You shouldn't have a corrosion issue down there like we do up here, but you never know.

I bought a Tech 2 scanner I’ll scan it this weekend and see what I getY code is a bare bones DB2 non turbo engine . Reason I asked was sometimes the P vans are behind the trucks in tech . You really need to get a scanner on there , as others have stated . Are all the wires OK , especially the engine speed sensor ?

Attachments

MrMarty51

Well-Known Member

Thats a nice tool to have.

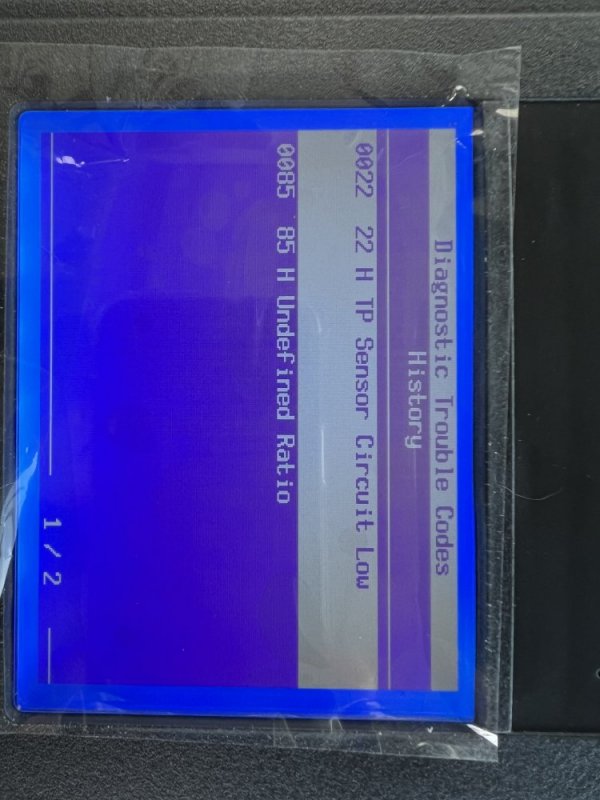

These are the trouble codesSo you eliminated one problem with the TPS out of adjustment.

Why did you replace the sensors on the side of the trans?

I assume you have cleaned the grounds, but, if you haven't: Look for the ECM ground generally by the trans dipstick on the passenger side engine head. Take it apart and clean it. Battery cables grounds and positive need to be in good shape. A stiff cable with corrosion leaking out of it is a problem. Load test the battery. Any electrical brownouts can cause a ECM to screw up.

You have two choices on how to fix this:

Dumb Luck:

Inspecting the wiring and sensors I mentioned on the last page. Including swapping the plugs on the two speed sensors you swapped out just in case they are backwards.

Renting someone with a Tech 2 and their experience using it:

It will tell them why the engine is revving up before shifting. Simply one of the sensors is not working, hooked up wrong, or shorted. Worst case the ECM has died of old age, but, they are dead last to assume has failed.

Attachments

You haven't answered my questions. Why did you replace the sensors on the side of the trans? Were they full of metal? Did you clean the grounds?

If the Code 22 comes back raise the TPS voltage to 0.6V. (Snapping the throttle closed may jar the sensor below 0.5V. Meter accuracy etc.) The Sensor may have a bad spot in it where it drops to 0.0V or a spot rubbed through the harness on the intake manifold.

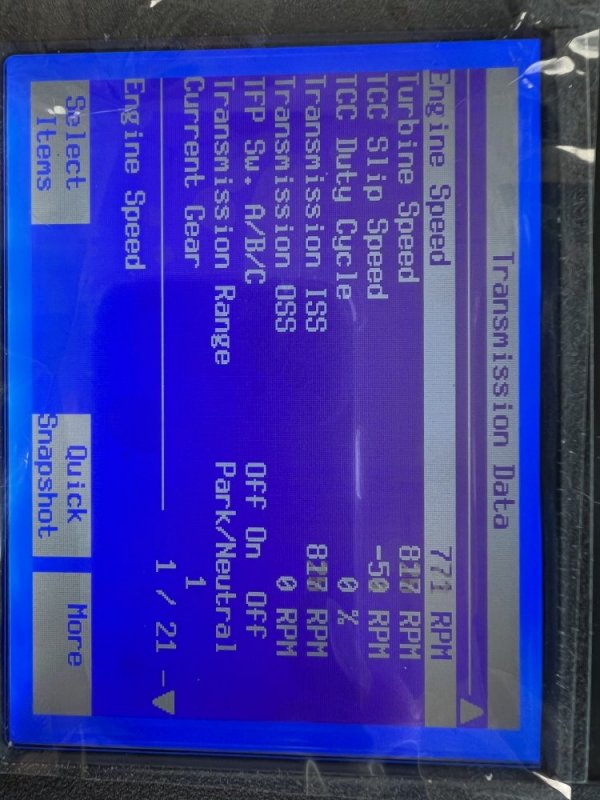

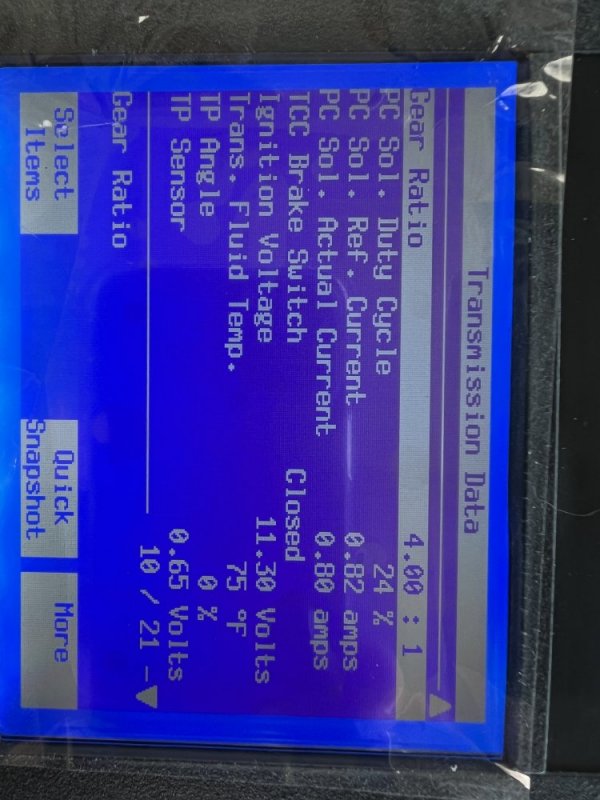

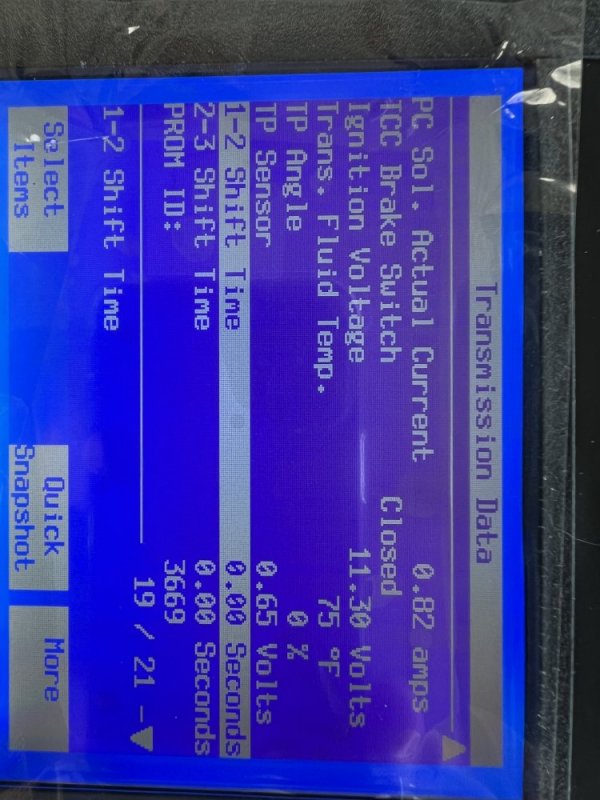

I suggest looking at Input RPM on transmission, stopped in park or N, engine at idle. Also output RPM. Again just in case the plugs got swapped. Then look at the RPM's while moving: they both need to read "Not Zero" RPM.

Otherwise Code 85 is transmission not shifting properly as commanded for any number of reasons.

If the Code 22 comes back raise the TPS voltage to 0.6V. (Snapping the throttle closed may jar the sensor below 0.5V. Meter accuracy etc.) The Sensor may have a bad spot in it where it drops to 0.0V or a spot rubbed through the harness on the intake manifold.

I suggest looking at Input RPM on transmission, stopped in park or N, engine at idle. Also output RPM. Again just in case the plugs got swapped. Then look at the RPM's while moving: they both need to read "Not Zero" RPM.

Otherwise Code 85 is transmission not shifting properly as commanded for any number of reasons.

I was told the sensors are a problem try and change them that is the reason.You haven't answered my questions. Why did you replace the sensors on the side of the trans? Were they full of metal? Did you clean the grounds?

If the Code 22 comes back raise the TPS voltage to 0.6V. (Snapping the throttle closed may jar the sensor below 0.5V. Meter accuracy etc.) The Sensor may have a bad spot in it where it drops to 0.0V or a spot rubbed through the harness on the intake manifold.

I suggest looking at Input RPM on transmission, stopped in park or N, engine at idle. Also output RPM. Again just in case the plugs got swapped. Then look at the RPM's while moving: they both need to read "Not Zero" RPM.

Otherwise Code 85 is transmission not shifting properly as commanded for any number of reasons.

Attachments

ak diesel driver

6.5 driver

One of the things that jumped out at me was ignition voltage. If that's with the engine running it's way too low. Low voltage can cause weird issues.

How can I fix that voltage?One of the things that jumped out at me was ignition voltage. If that's with the engine running it's way too low. Low voltage can cause weird issues.