consaka

Active Member

(waving little flag) I hereby claim this tiny space for people to watch the strange stuff I do on an old 1983 van I inherited from my grandfather.

My grandfather ordered this Chevy van new in 1983. The only new vehicle he ever bought I believe. His goal was to retire and drive around the country sightseeing and helping some buddies build churches and schools and whatnot. Some maranatha friends I think. To that end he bought a barebones passenger window van and removed all the rear seats. Mind you he was a logger first and in his 40's went back to school and both him and my grandmother got teaching degrees. I point this out because he was NOT a carpenter. Regardless he had someone weld together a metal frame for a back seat that made into a bed. Still there and a little more comfortable than sleeping on rocks naked. he then built two cabinets for each side. One shorter than the other went from the bed to the middle of the sliding door. The other went from the bed all the way to the driver's seat. It had a little sink and a hand pump for water that of course mostly never worked. He built all of this himself and was quite proud of it. Any serious accident and we will all be dead from flying fragments of stuff.

He wired in this and that over the years with the regular attention to detail that you could expect from a half blind farmer. I took out one cabinet because it was just too cramped for 4 of us. I also added a fridge that runs on an inverter. I also added a total of 4 batteries. 3 to start and 3 to run the fridge. yeah yeah I know they should be deep cycle but they aren't. They work mostly.

When I got the van the engine was a 6.2 with 222,143? miles on it. It sat in front of a stock 700r4. The dealer had told him never to tow with it. He claimed 25 mpg when it was new. He isn't or wasn't ever a mechanic or carpenter so new meant he drove 50 mph in a 55 zone. Remember them were the days of 55mph limits. So yeah he probably had no trouble getting 25mpg. The only thing that had ever been done on that van was the injection pump had been replaced after some attendant(cant pump your own gas in Oregon) at Cenex filled it with regular unleaded.

We got it in 1995, the year I graduated from college and immediately used it quite a bit. So handy to drive till you are tired then stop and crawl in the back and take a nap. But there were some problems. Fully loaded semis could pass us on the grades - going up. 140HP just wasn't up to a fully loaded van that included my two toolboxes I carry everywhere. Then I begin to notice a knocking sound. It seemed like a faint knocking sound until you drove next to a concrete divider. Then it sounded like your engine was about to blow up.

My solution was to put a turbocharged 6.5 in it. which worked great for a year till one of the cheapo pistons I bought decided to melt itself to the cylinder wall and then split that same wall when it no longer fit. All on flat ground cruising. Engine wasn't even fully hot yet.

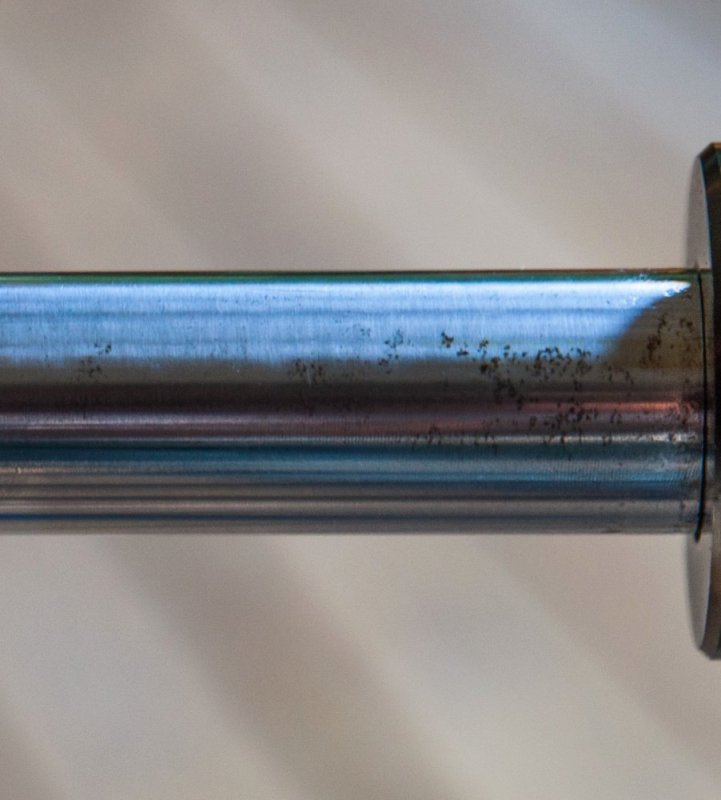

Replaced that engine with a Peninsular design marine engine and new junkyard block. Wow the power was great. Just no oil pressure when hot at idle. Well that was 65 to 80 thousand miles ago and its time to fix that problem. I got a new engine on the stand being built just like it only this time I'm using some coatings to help control and isolate the heat where it is supposed to be.

Oh and some other things happened in there too. That new engine with near 300 some horsepower didn't like my transmission any more. Brand new transmission with very little towing only last 2 years. So I put a 4L80E in with a PCS controller. I liked the controller so well I got to be a dealer for them and sell it on my website. After that nice transmission went in the rear axle decided it didn't like the engine and transmission ganging up on it so it busted a few teeth off that made driving very noisy. Well I hate those cheesy 1/2 ton crap axles with the bearing that wears a groove directly on the axle so it knows where to snap off. dumbest design I ever saw. So I got an 14 bolt full floater out of a 1 ton 1979 van. Saved up and put a arb locker in it.

Some years later I ran into some guys that claimed they could put a 4x4 front axle in it for a reasonable price. They were wrong and I have been fixing it and teaching myself 4x4 suspension basics and fixing it again ever since. They took a spring from the front of a regular van and cut it in half. they stuck each half between the axle and the frame. Then they cross the drag link and the panhard bar so those formed an X shape. The axle was located by what looked like some kind of 3 link and they told me it was a 3 link but really it was a radius arm on the drivers side and a single link on the passenger side. Rode like crap and blew all the seals out of the steering box on the way home. I got some ford f250 spring buckets and springs from the junkyard and made them put a real suspension under it and made them put the panhard bar as close to the drag link length and parallel as possible. it was drivable then. I have since put a 4 link under it with cheap coilovers. I have plans to get more travel out of the coilovers which means I have to rebuild all the brackets. but that is another story. Oh and I did put a nice limited slip in the front when I rebuilt that because the axle they gave was pretty much rusted junk. And that is where we sit today..

My grandfather ordered this Chevy van new in 1983. The only new vehicle he ever bought I believe. His goal was to retire and drive around the country sightseeing and helping some buddies build churches and schools and whatnot. Some maranatha friends I think. To that end he bought a barebones passenger window van and removed all the rear seats. Mind you he was a logger first and in his 40's went back to school and both him and my grandmother got teaching degrees. I point this out because he was NOT a carpenter. Regardless he had someone weld together a metal frame for a back seat that made into a bed. Still there and a little more comfortable than sleeping on rocks naked. he then built two cabinets for each side. One shorter than the other went from the bed to the middle of the sliding door. The other went from the bed all the way to the driver's seat. It had a little sink and a hand pump for water that of course mostly never worked. He built all of this himself and was quite proud of it. Any serious accident and we will all be dead from flying fragments of stuff.

He wired in this and that over the years with the regular attention to detail that you could expect from a half blind farmer. I took out one cabinet because it was just too cramped for 4 of us. I also added a fridge that runs on an inverter. I also added a total of 4 batteries. 3 to start and 3 to run the fridge. yeah yeah I know they should be deep cycle but they aren't. They work mostly.

When I got the van the engine was a 6.2 with 222,143? miles on it. It sat in front of a stock 700r4. The dealer had told him never to tow with it. He claimed 25 mpg when it was new. He isn't or wasn't ever a mechanic or carpenter so new meant he drove 50 mph in a 55 zone. Remember them were the days of 55mph limits. So yeah he probably had no trouble getting 25mpg. The only thing that had ever been done on that van was the injection pump had been replaced after some attendant(cant pump your own gas in Oregon) at Cenex filled it with regular unleaded.

We got it in 1995, the year I graduated from college and immediately used it quite a bit. So handy to drive till you are tired then stop and crawl in the back and take a nap. But there were some problems. Fully loaded semis could pass us on the grades - going up. 140HP just wasn't up to a fully loaded van that included my two toolboxes I carry everywhere. Then I begin to notice a knocking sound. It seemed like a faint knocking sound until you drove next to a concrete divider. Then it sounded like your engine was about to blow up.

My solution was to put a turbocharged 6.5 in it. which worked great for a year till one of the cheapo pistons I bought decided to melt itself to the cylinder wall and then split that same wall when it no longer fit. All on flat ground cruising. Engine wasn't even fully hot yet.

Replaced that engine with a Peninsular design marine engine and new junkyard block. Wow the power was great. Just no oil pressure when hot at idle. Well that was 65 to 80 thousand miles ago and its time to fix that problem. I got a new engine on the stand being built just like it only this time I'm using some coatings to help control and isolate the heat where it is supposed to be.

Oh and some other things happened in there too. That new engine with near 300 some horsepower didn't like my transmission any more. Brand new transmission with very little towing only last 2 years. So I put a 4L80E in with a PCS controller. I liked the controller so well I got to be a dealer for them and sell it on my website. After that nice transmission went in the rear axle decided it didn't like the engine and transmission ganging up on it so it busted a few teeth off that made driving very noisy. Well I hate those cheesy 1/2 ton crap axles with the bearing that wears a groove directly on the axle so it knows where to snap off. dumbest design I ever saw. So I got an 14 bolt full floater out of a 1 ton 1979 van. Saved up and put a arb locker in it.

Some years later I ran into some guys that claimed they could put a 4x4 front axle in it for a reasonable price. They were wrong and I have been fixing it and teaching myself 4x4 suspension basics and fixing it again ever since. They took a spring from the front of a regular van and cut it in half. they stuck each half between the axle and the frame. Then they cross the drag link and the panhard bar so those formed an X shape. The axle was located by what looked like some kind of 3 link and they told me it was a 3 link but really it was a radius arm on the drivers side and a single link on the passenger side. Rode like crap and blew all the seals out of the steering box on the way home. I got some ford f250 spring buckets and springs from the junkyard and made them put a real suspension under it and made them put the panhard bar as close to the drag link length and parallel as possible. it was drivable then. I have since put a 4 link under it with cheap coilovers. I have plans to get more travel out of the coilovers which means I have to rebuild all the brackets. but that is another story. Oh and I did put a nice limited slip in the front when I rebuilt that because the axle they gave was pretty much rusted junk. And that is where we sit today..