Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome to The Truck Stop! We see you haven't REGISTERED yet.

Your truck knowledge is missing!

- Registration is FREE , all we need is your birthday and email. (We don't share ANY data with ANYONE)

- We have tons of knowledge here for your diesel truck!

- Post your own topics and reply to existing threads to help others out!

- NO ADS! The site is fully functional and ad free!

Problems registering? Click here to contact us!

Already registered, but need a PASSWORD RESET? CLICK HERE TO RESET YOUR PASSWORD!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Trouble with the Optimizer 6.5

- Thread starter bobbiemartin

- Start date

bobbiemartin

Author of The DB2 Conversion Guide

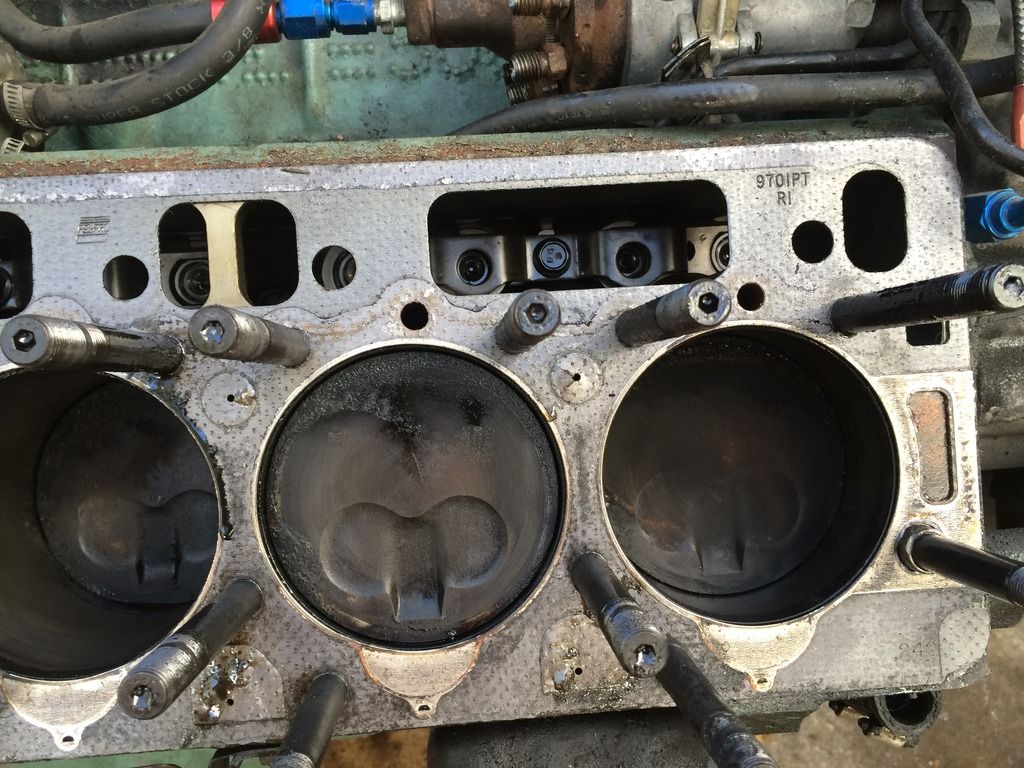

I looks like maybe there was water getting in 2 cylinders, but hard to say. You can still see the crosshatch in the cylinders, so very little wear. All the pushrods & rockers looked good. The bottom of the valve covers were spotless. BTW, every molecule of air this engine took in came through a K&N, so I would say it filters just fine

I would spin the engine over by hand and check the piston height. Bent rods from too much power, liquids in the chambers like: coolant, water, or oil. CDR ProVent maybe a source of oil? (Restricted and sucked oil from the drain or overflowed. Massive blowby overwhelmed it? Just thinking out loud here.)

The "clean" valve is a concern - why is it spotless? Valve guide dumping oil maybe?

The amount of "dirt" in the combustion chamber is a concern: is the engine burning oil? Turbo shaft seal? Hole in the intake letting dirt in? I don't see this kind of build up in the engines I have torn down, but, I ran them hard. ( I did see it in the 1992 with extreme miles and oil burning from the CDR blowby / bad rings issue...)

Did the valves hit the pistons and get bent? I would inspect the timing chain - it's due at 60K anyway and Leroy has a gear kit to eliminate that problem chain now...

Maybe a lifter came apart and ate the camshaft - some sort of INOP valves or intake restriction?

Possible carbon, from the pictured mess of a buildup breaking loose, is sticking some valves open?

Ring failure or defect causing them to loose tension?

As the heads are being checked one has to check the block for warping. I didn't see any signs of a blown head gasket, but, I am not there and it's hard to see.

The "clean" valve is a concern - why is it spotless? Valve guide dumping oil maybe?

The amount of "dirt" in the combustion chamber is a concern: is the engine burning oil? Turbo shaft seal? Hole in the intake letting dirt in? I don't see this kind of build up in the engines I have torn down, but, I ran them hard. ( I did see it in the 1992 with extreme miles and oil burning from the CDR blowby / bad rings issue...)

Did the valves hit the pistons and get bent? I would inspect the timing chain - it's due at 60K anyway and Leroy has a gear kit to eliminate that problem chain now...

Maybe a lifter came apart and ate the camshaft - some sort of INOP valves or intake restriction?

Possible carbon, from the pictured mess of a buildup breaking loose, is sticking some valves open?

Ring failure or defect causing them to loose tension?

As the heads are being checked one has to check the block for warping. I didn't see any signs of a blown head gasket, but, I am not there and it's hard to see.

Last edited:

FellowTraveler

Well-Known Member

I would spin the engine over by hand and check the piston height. Bent rods from too much power, liquids in the chambers like: coolant, water, or oil. CDR ProVent maybe a source of oil? (Restricted and sucked oil from the drain or overflowed. Massive blowby overwhelmed it? Just thinking out loud here.)

The "clean" valve is a concern - why is it spotless? Valve guide dumping oil maybe?

The amount of "dirt" in the combustion chamber is a concern: is the engine burning oil? Turbo shaft seal? Hole in the intake letting dirt in? I don't see this kind of build up in the engines I have torn down, but, I ran them hard. ( I did see it in the 1992 with extreme miles and oil burning from the CDR blowby / bad rings issue...)

Did the valves hit the pistons and get bent? I would inspect the timing chain - it's due at 60K anyway and Leroy has a gear kit to eliminate that problem chain now...

Maybe a lifter came apart and ate the camshaft - some sort of INOP valves or intake restriction?

Possible carbon, from the pictured mess of a buildup breaking loose, is sticking some valves open?

Ring failure or defect causing them to loose tension?

As the heads are being checked one has to check the block for warping. I didn't see any signs of a blown head gasket, but, I am not there and it's hard to see.

I suspect valves impacting & chain slack too...........

dieselolds

Well-Known Member

Good luck with the repair bobbie.Keep us updated.

bobbiemartin

Author of The DB2 Conversion Guide

I didn't see any damage to the lifters or valvetrain. I really doubt the timing chain has a problem, but I'll check it out. I'm still deciding what to do, maybe fix it, maybe sell the engine or the whole truck as is.

We would love to know what caused the loss of compression before you 'dump' it. You have a lot of fans out there of the guide and of this build. The engine under DD use shouldn't have failed. Do consider that 60,000 miles is a lot of miles so you did get some value out of the 3rd engine. Sure they should go 100K or more, but, things happen. Hopefully the engine can be patched cheaply and dropped back in.

uniquediesel

1/4 mi. Fan

- Messages

- 245

- Reaction score

- 38

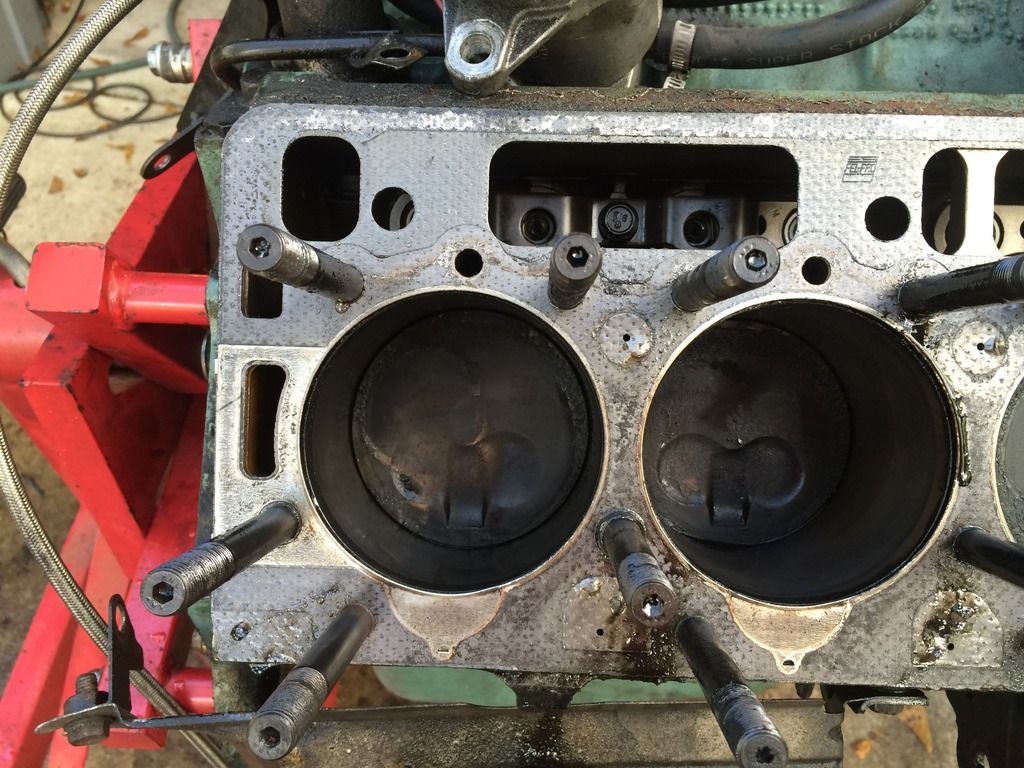

I see a few issues with your head gaskets. There appears to be a few places where you're not getting good seating. What's holding it up? I see one thing so far. The block dowels appear to be damaged. This may have been at rebuild or trying to install heads over the studs.

I'm uploading one that I caught that is causing you grief.

Also, I'd ditch the head studs, these things cause nothing but grief in sealing and compromising the head gasket seal by it getting wet at the threads. They also cause alignment issues when trying to install a head gasket over them and then then head.

I'd clean these heads up and deck surface, replace the dowels, and install with new head gaskets and new heads bolts.

Been there

I'm uploading one that I caught that is causing you grief.

Also, I'd ditch the head studs, these things cause nothing but grief in sealing and compromising the head gasket seal by it getting wet at the threads. They also cause alignment issues when trying to install a head gasket over them and then then head.

I'd clean these heads up and deck surface, replace the dowels, and install with new head gaskets and new heads bolts.

Been there

Attachments

jrsavoie

Recruit

They should go 500,000 or moreWe would love to know what caused the loss of compression before you 'dump' it. You have a lot of fans out there of the guide and of this build. The engine under DD use shouldn't have failed. Do consider that 60,000 miles is a lot of miles so you did get some value out of the 3rd engine. Sure they should go 100K or more, but, things happen. Hopefully the engine can be patched cheaply and dropped back in.

bobbiemartin

Author of The DB2 Conversion Guide

Thanks, I'll check that out. I was thinking of going back to bolts anyway.I see a few issues with your head gaskets. There appears to be a few places where you're not getting good seating. What's holding it up? I see one thing so far. The block dowels appear to be damaged. This may have been at rebuild or trying to install heads over the studs.

I'm uploading one that I caught that is causing you grief.

Also, I'd ditch the head studs, these things cause nothing but grief in sealing and compromising the head gasket seal by it getting wet at the threads. They also cause alignment issues when trying to install a head gasket over them and then then head.

I'd clean these heads up and deck surface, replace the dowels, and install with new head gaskets and new heads bolts.

Been there

ARP has updated the instructions to use sealer on wet threads. (And I have been spreading the word to use locktight as a sealer since before the update. Also tighten them into the block rather than being hand tight.)

I find the studs do quite well over bolts that stretch and let go esp. when you put the power and boost to it. ARP's are proven on many engines. Only 6.2/6.5 engines I am not keeping get new bolts vs. studs.

In fact this ran from downtown to home without popping the head gasket. Sure new slugs and valves later it's back on the road and with zero head bolt expense. The heads have been off the engine for inspection after totaling the truck and this FOD overhaul. So the studs have paid for themselves.

I find the studs do quite well over bolts that stretch and let go esp. when you put the power and boost to it. ARP's are proven on many engines. Only 6.2/6.5 engines I am not keeping get new bolts vs. studs.

In fact this ran from downtown to home without popping the head gasket. Sure new slugs and valves later it's back on the road and with zero head bolt expense. The heads have been off the engine for inspection after totaling the truck and this FOD overhaul. So the studs have paid for themselves.

Will L.

Well-Known Member

Adjustable piston top, I like it!

Yeah build a $10,000 + engine and use tty bolts instead of arp- not gonna happen. Y? Cuz they work better, period.

If you choose however to sell them at say 50% just speak up - they'll be gone in a couple days.

ARP guy said they never looked at 6.2/6.5 platform, just kept getting the requests and were told dry holes and 18:1 compression. (Wonder who floated that, haha). 18 is there cut off for tightening the studs vs floating them. Once you go over on any engine you'll find their instructions say torque them. Also minor detail of filled holes vs coolant passages makes it a wet hole, so there ya go.

Dag-gum twin turbo (sometimes ones blown), tractor pullers confusing our suppliers just cuz they been doin it since the 90's. I blame Paul, he lives with the those guys in that bee hive state. If you see Jeremy and Ron btw, NEVER go to Moab with em. They'll flip your rig for ya.

Seriously back on track though, good eye on the dowel pin! I could see that goofing up one head on compression, but what for the other side? I think there's a clue missing somewhere still. And the front 2 cylinders had good numbers and that's where the bad pin is. Did you straight edge the heads or pull the Pistons yet to check rings?

Yeah build a $10,000 + engine and use tty bolts instead of arp- not gonna happen. Y? Cuz they work better, period.

If you choose however to sell them at say 50% just speak up - they'll be gone in a couple days.

ARP guy said they never looked at 6.2/6.5 platform, just kept getting the requests and were told dry holes and 18:1 compression. (Wonder who floated that, haha). 18 is there cut off for tightening the studs vs floating them. Once you go over on any engine you'll find their instructions say torque them. Also minor detail of filled holes vs coolant passages makes it a wet hole, so there ya go.

Dag-gum twin turbo (sometimes ones blown), tractor pullers confusing our suppliers just cuz they been doin it since the 90's. I blame Paul, he lives with the those guys in that bee hive state. If you see Jeremy and Ron btw, NEVER go to Moab with em. They'll flip your rig for ya.

Seriously back on track though, good eye on the dowel pin! I could see that goofing up one head on compression, but what for the other side? I think there's a clue missing somewhere still. And the front 2 cylinders had good numbers and that's where the bad pin is. Did you straight edge the heads or pull the Pistons yet to check rings?

uniquediesel

1/4 mi. Fan

- Messages

- 245

- Reaction score

- 38

It's not that heads studs are bad, it's the application of them that's difficult with them not being installed in Blind Holes.

ARP's own sealant is garbage which leads you to try other things with mixed results. I'm going to learn to not offer advise on head studs because everyone seems to have there own opinions on them.

The reality is that they're really hard to seal, the thread pitch is tight and most sealant you apply squeezes off the threads upon entry. The lock-tite idea is really one of two ways that could seal, because of it's liquid consistency being able to fill the threads and stay there until it dries.

If you do lots of these engines and have a technique that you've developed that works, great. For everyone else doing it for the first or maybe the second or third time in an engine that technique may not be mature and this leads to a high probability to a leak. It only takes 1 stud leak out of 17 per side to cause you grief.

There is a specific reason why GM went with a dry sealant on the bolts, and it wasn't just for assembly time, it was because it was absolutely necessary to keep the bolts to from leaking. They also seal the underside of the head of the bolt just in case. I've pulled engines apart that did not have any head gasket issues and found bolts that were rusty on the shaft because coolant had gotten past the threads in the deck. Fortunately, it was sealed with the head bolt not letting coolant into the oil.

With studs, you only get one shot for sealing, at the threads in the deck, better be really good. With a bolt you get two.

You can't seal the threads on the top of a stud from leaking if the threads in the deck go to leaking.

The TTY bolts are not a problem and work really well if they are installed correctly by torque and then by angle at the end. Plus, they're really inexpensive and just work great. For something that's going to get some miles on it, I'd go with bolts 100% of the time and just plan on doing gaskets at the 125k mark. At least in the 125k miles you won't be pulling it apart because of an internal coolant leak into the engine, or externally on some bolts.

What about higher boost? Need Studs? No, not really, the gasket will fail before the bolt the gasket is the cause of the gasket failure. What's higher boost, that's subjective; anything above factory for sure. The gasket is the weak link, look where they fail 75% of the time at the coolant ports on the end. Fastener will not help you there.

Seriously, if you're running high boost, it ain't gonna last long term anyways gasket wise. For boost levels under 25psi, you're fine with bolts.

Studs are meant for holding power, yes, and re-usability, to a degree. Must be checked when new for length and after stretch, there is a limit to when they should not be re-used due to stretch.

I'd take a set of non TTY bolts over studs any day regardless of application. You can get re-usable non TTY Bolts for these engines, that'd be a way to go.

ARP's own sealant is garbage which leads you to try other things with mixed results. I'm going to learn to not offer advise on head studs because everyone seems to have there own opinions on them.

The reality is that they're really hard to seal, the thread pitch is tight and most sealant you apply squeezes off the threads upon entry. The lock-tite idea is really one of two ways that could seal, because of it's liquid consistency being able to fill the threads and stay there until it dries.

If you do lots of these engines and have a technique that you've developed that works, great. For everyone else doing it for the first or maybe the second or third time in an engine that technique may not be mature and this leads to a high probability to a leak. It only takes 1 stud leak out of 17 per side to cause you grief.

There is a specific reason why GM went with a dry sealant on the bolts, and it wasn't just for assembly time, it was because it was absolutely necessary to keep the bolts to from leaking. They also seal the underside of the head of the bolt just in case. I've pulled engines apart that did not have any head gasket issues and found bolts that were rusty on the shaft because coolant had gotten past the threads in the deck. Fortunately, it was sealed with the head bolt not letting coolant into the oil.

With studs, you only get one shot for sealing, at the threads in the deck, better be really good. With a bolt you get two.

You can't seal the threads on the top of a stud from leaking if the threads in the deck go to leaking.

The TTY bolts are not a problem and work really well if they are installed correctly by torque and then by angle at the end. Plus, they're really inexpensive and just work great. For something that's going to get some miles on it, I'd go with bolts 100% of the time and just plan on doing gaskets at the 125k mark. At least in the 125k miles you won't be pulling it apart because of an internal coolant leak into the engine, or externally on some bolts.

What about higher boost? Need Studs? No, not really, the gasket will fail before the bolt the gasket is the cause of the gasket failure. What's higher boost, that's subjective; anything above factory for sure. The gasket is the weak link, look where they fail 75% of the time at the coolant ports on the end. Fastener will not help you there.

Seriously, if you're running high boost, it ain't gonna last long term anyways gasket wise. For boost levels under 25psi, you're fine with bolts.

Studs are meant for holding power, yes, and re-usability, to a degree. Must be checked when new for length and after stretch, there is a limit to when they should not be re-used due to stretch.

I'd take a set of non TTY bolts over studs any day regardless of application. You can get re-usable non TTY Bolts for these engines, that'd be a way to go.

uniquediesel

1/4 mi. Fan

- Messages

- 245

- Reaction score

- 38

Bobbie's engine:

I see places on the gasket where it doesn't look like the head was compressed into the gasket properly. Could be any of the dowels holding it up, several of them look like they're marred which is all it takes to provide resistance to the head being compressed into the gasket and held to the block by fastener stretch.

Other issues could be the block's deck surface being straight. Was this block decked? This needs to be checked.

The cylinder heads themselves could be untrue, this needs to be checked as well.

Since this engine is MFI it could be rigged to start on a stand. Make the repairs to the head/gasket situation and re-assemble on the stand good enough to fire up. Run it, then pull compression and see if the repairs solved the problem.

I see places on the gasket where it doesn't look like the head was compressed into the gasket properly. Could be any of the dowels holding it up, several of them look like they're marred which is all it takes to provide resistance to the head being compressed into the gasket and held to the block by fastener stretch.

Other issues could be the block's deck surface being straight. Was this block decked? This needs to be checked.

The cylinder heads themselves could be untrue, this needs to be checked as well.

Since this engine is MFI it could be rigged to start on a stand. Make the repairs to the head/gasket situation and re-assemble on the stand good enough to fire up. Run it, then pull compression and see if the repairs solved the problem.

GM Guy

Manual Trans. 2WD Enthusiast

Interested to see how it turns out, we are all rooting for a healthy 6.5L back in the burb!

Also, I'd ditch the head studs, these things cause nothing but grief in sealing and compromising the head gasket seal by it getting wet at the threads. They also cause alignment issues when trying to install a head gasket over them and then then head.

At first I would be mean and say something like 'don't mistake a lack of talent for using the studs', but, it's deeper than that. Those of you that have gone before me and posted up their ARP misery is why I am having good luck with them. Maybe it was your posts, but, somewhere I read about the ARP's leaking. So a known thread sealer, Red lock tight, went on and then double nut to torque the studs into the block - risking dimpling the block at the shoulder of the stud. These studs will NEVER come out of the block for sure. (Red was used as budget didn't allow for a tube of blue and Red was on hand at the time.) The next set used blue and only as tight as the allen wrench would get them.

Yes, you put the gasket on first and then put the studs in. Otherwise you have to carefully put the head gasket over the studs - say if you used red lock tight and this is the 2nd time the heads are off... It's a $50 mistake if you are not careful...

So I suggest you reconsider ARP's in 6.5's because failures and problems you experienced have been corrected in part from what failures you went through.

Others posted on here go as far as o-ringing the studs to stop leaks. IMO not necessary, but, no kill like overkill.

Bolts are proven to stretch, break, or loose clamping force and pop the HG's generally average around 200K. Some more some less.

uniquediesel

1/4 mi. Fan

- Messages

- 245

- Reaction score

- 38

Bolts are proven to stretch, break, or loose clamping force and pop the HG's generally average around 200K. Some more some less.

Thank you! You just made my case! What in the world is wrong with something that lasts for 200k miles.

Nothing's perfect, the TTY bolts do fail, sure. I've seen soft ones made that wouldn't hold torque new. Stuff happens in the production word.

Just saying that a person doing head gaskets will have a much higher success using bolts than studs.

Try building an engine for a customer with studs in it and having confidence that it won't come back because of them.

I've said my peace.

bobbiemartin

Author of The DB2 Conversion Guide

The block was bored and check when at the machine shop. I told them to do what it needed, they said the deck & main bores were fine. Heads were new AMG .Other issues could be the block's deck surface being straight. Was this block decked? This needs to be checked.

The cylinder heads themselves could be untrue, this needs to be checked as well.

I planning on doing something like this but using the starter to check compression, not running it.Since this engine is MFI it could be rigged to start on a stand. Make the repairs to the head/gasket situation and re-assemble on the stand good enough to fire up. Run it, then pull compression and see if the repairs solved the problem.

Thank you! You just made my case! What in the world is wrong with something that lasts for 200k miles.

Nothing's perfect, the TTY bolts do fail, sure. I've seen soft ones made that wouldn't hold torque new. Stuff happens in the production word.

Just saying that a person doing head gaskets will have a much higher success using bolts than studs.

Try building an engine for a customer with studs in it and having confidence that it won't come back because of them.

I've said my peace.

Stock power when gas engines are now lasting 200K is nothing wrong IF it makes it that long. But, addressing weak points is the reason ARP studs are popular. On a Stock Cummins 5.9 I don't see the reason for ARP's as their bolts go 500K-1 million miles or more, but I recommend it on the 6.5 because the head bolt count isn't very high for a diesel. Go crazy on power/boost on a 5.9 and you are reaching for ARP's. Granted a 6.5 is not a Olds 5.7 hand grenade low head bolt count... (But the 5.7 and GM's lack of training gave TTY's a bad rep including shops that are stupid enough to reuse them - even today.)

Turning up the power/boost on 'weak point' TTY bolts with the relatively high compression of ~21:1 is why ARP's appeal to the masses. TTY's loose clamping force when pushed and then the head gasket(s) fails. Loss of clamping force leading to gasket failure is the concern ARP's are supposed to address.

There is no real warranty for going over stock power as you pay to play. But pulling heads 125K later can total/scrap a marginal vehicle that now has 200-300K on it.

I find it very interesting your perspective and this brought out Will's comment as to why ARP changed their directions and likely still need to add the tighten into the block step. In this way we could write a better guide to using studs like install gasket then studs, use good sealer, etc. It also makes my install using red locktight not as extreme nuts crazy as I thought it was. (It made sense at the time, but, so crazy in contrast to the instructions at that time.)

Absolutely agree on ARP sealer being a bad choice and thanks for explaining why.