bobbiemartin

Author of The DB2 Conversion Guide

It's been a while since I posted. Lots of other projects going on, but now having problems with the Suburban. Some may remember the rebuild a while back, here is the link: http://www.thetruckstop.us/forum/threads/my-suburban-renewal-project.14685/

It's been running fine, but a while back it (almost instantly) developed a miss. It was so bad I had it towed home. My first thought was a bad injector, so I removed them and sent them to a local diesel shop that has 6.5 experience. Got a call a few days later that all of them check out fine, in fact good enough they didn't have to do anything to them.

Other projects kept me from looking further, but over the weekend I finally got around to doing a compression check. These are the results:

1-425 PSI

3-125

5-275

7-100

2-400

4-200

6-450

8-200

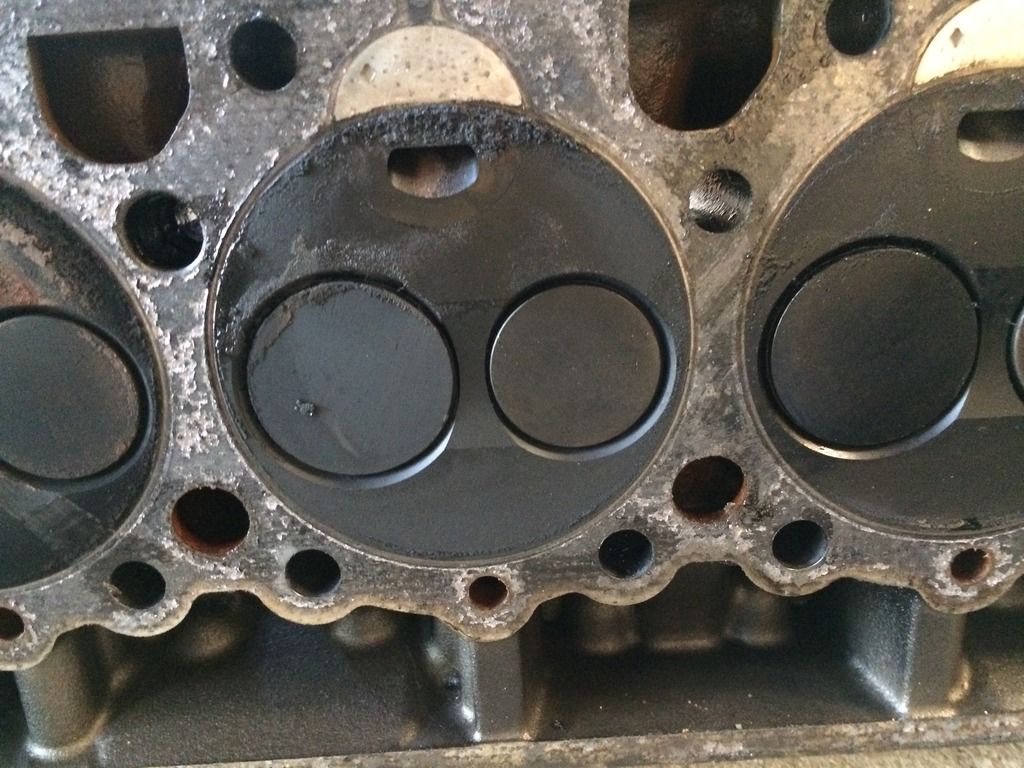

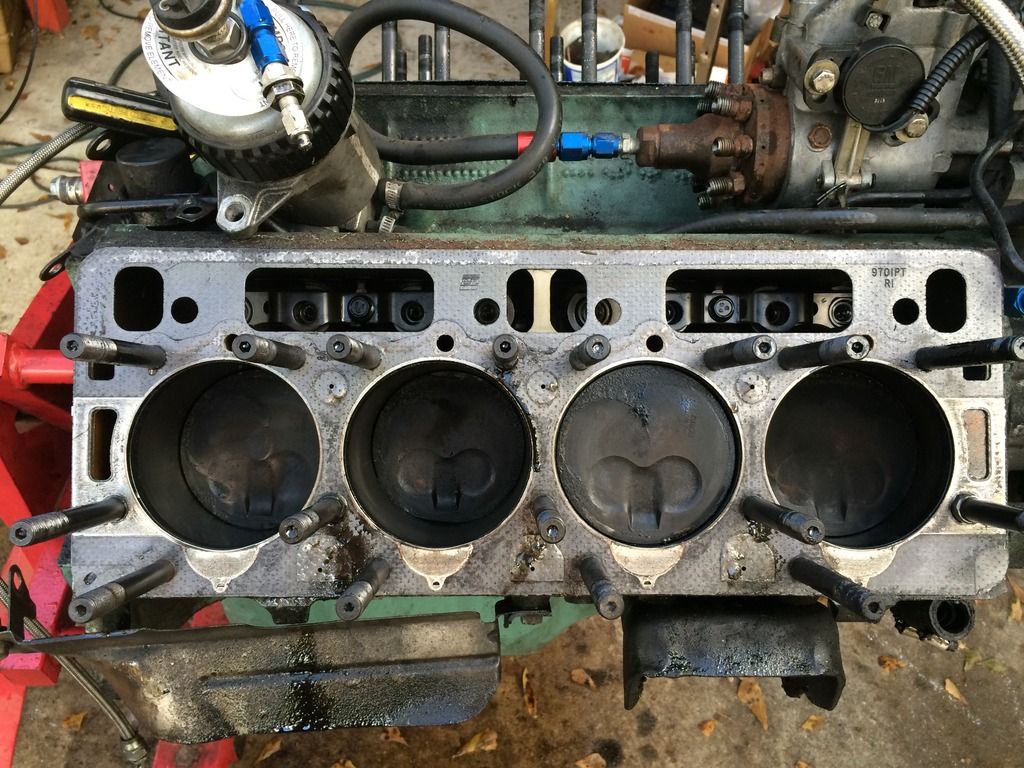

I guess the next step is to remove the heads and see what is going on. I'm thinking at best head gaskets. Not sure what else it could be or why both would go bad. It has never overheated or had any major problems. The block was checked over and the heads were new AMG's. I would hate to think one or both has a crack. Any ideas, let me know.

At this point we are really thinking about what to do. Come November, we will have owned it 20 years (we are original owners). If the engine is toast, I wouldn't put another 6.5 in it. It really depends, but thought about going 350 or newer LS type small block or possibly selling the entire thing. Once I get into it, I'll keep you posted.

It's been running fine, but a while back it (almost instantly) developed a miss. It was so bad I had it towed home. My first thought was a bad injector, so I removed them and sent them to a local diesel shop that has 6.5 experience. Got a call a few days later that all of them check out fine, in fact good enough they didn't have to do anything to them.

Other projects kept me from looking further, but over the weekend I finally got around to doing a compression check. These are the results:

1-425 PSI

3-125

5-275

7-100

2-400

4-200

6-450

8-200

I guess the next step is to remove the heads and see what is going on. I'm thinking at best head gaskets. Not sure what else it could be or why both would go bad. It has never overheated or had any major problems. The block was checked over and the heads were new AMG's. I would hate to think one or both has a crack. Any ideas, let me know.

At this point we are really thinking about what to do. Come November, we will have owned it 20 years (we are original owners). If the engine is toast, I wouldn't put another 6.5 in it. It really depends, but thought about going 350 or newer LS type small block or possibly selling the entire thing. Once I get into it, I'll keep you posted.