Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome to The Truck Stop! We see you haven't REGISTERED yet.

Your truck knowledge is missing!

- Registration is FREE , all we need is your birthday and email. (We don't share ANY data with ANYONE)

- We have tons of knowledge here for your diesel truck!

- Post your own topics and reply to existing threads to help others out!

- NO ADS! The site is fully functional and ad free!

Problems registering? Click here to contact us!

Already registered, but need a PASSWORD RESET? CLICK HERE TO RESET YOUR PASSWORD!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

On the road again

- Thread starter axeman

- Start date

smokymtn65

Well-Known Member

Welcome, my favorite right there!

Jaryd

Extremely Deplorable

Good looking truck. Square body trucks like that look tuff as hell.

Will L.

Well-Known Member

Love the square bodies.

Planning on keeping it for a long time, I would go fluidampr balancer, gapless rings. Leroy gets them. Also the injectors and a pump. Stock pump or bumped up a bit? make sure hardened internals for ulsd.

You still have v belt 4 bolt pump I take it? If so, the hmmwv fan clutch for 100% lockup and control to engage it whenever you want- like bottom of a big hill when towing. Also can have it engage when the a/c is on if you want for colder a/c in stop and go traffic.

96 military take out=GM block not optimizer from GEP. rethink that imo. if he pulls it apart and the block is perfect then ok. But not if it has the slightest of problems. double check 2 rear cylinder specs real close, main webs, and heads.

keep us up on the progress

Planning on keeping it for a long time, I would go fluidampr balancer, gapless rings. Leroy gets them. Also the injectors and a pump. Stock pump or bumped up a bit? make sure hardened internals for ulsd.

You still have v belt 4 bolt pump I take it? If so, the hmmwv fan clutch for 100% lockup and control to engage it whenever you want- like bottom of a big hill when towing. Also can have it engage when the a/c is on if you want for colder a/c in stop and go traffic.

96 military take out=GM block not optimizer from GEP. rethink that imo. if he pulls it apart and the block is perfect then ok. But not if it has the slightest of problems. double check 2 rear cylinder specs real close, main webs, and heads.

keep us up on the progress

ak diesel driver

6.5 driver

Might want to check the oil pan. I know older pans won't fit newer trucks but not sure on the reverse.

Where have I seen a 6.5 on a trailer behind a Dodge Cummins before?

You running a serpentine belt? Reverse rotation HO water pump upgrades don't work with V belts or the V belt water pump backing plate.

I wouldn't spend 10cents on the GM cast 6.2/6.5 engine for machine work. New cam bearings yes. High Volume oil pump, yes. Anything else the risk of cracks before it's time would have me start over with a improved casting take out Optimizer. I would suggest you don't touch the crankshaft bolts - the stresses are already there and settled in. A re-torque is new stresses. That's my theory and I am sticking too it. Rod bearings will indicate if you need to look at the crankshaft bearings.

Compression test is a waste of time and money. Just pop the pistons out and put in new rings. Gapless rings. Deglaze the walls with the crankshaft in place. You likely will have blowby with the military rings from abuse (getting hot) or not seating well. It's not worth the money to go 0.x over on GM cast blocks. Deglaze, ignore everything but show stopper condition of cylinders otherwise, new rings and off you go.

Money is best spent looking for cracks in the heads, main webs, and cylinders.

Head studs are another good option since you are there.

You running a serpentine belt? Reverse rotation HO water pump upgrades don't work with V belts or the V belt water pump backing plate.

I wouldn't spend 10cents on the GM cast 6.2/6.5 engine for machine work. New cam bearings yes. High Volume oil pump, yes. Anything else the risk of cracks before it's time would have me start over with a improved casting take out Optimizer. I would suggest you don't touch the crankshaft bolts - the stresses are already there and settled in. A re-torque is new stresses. That's my theory and I am sticking too it. Rod bearings will indicate if you need to look at the crankshaft bearings.

Compression test is a waste of time and money. Just pop the pistons out and put in new rings. Gapless rings. Deglaze the walls with the crankshaft in place. You likely will have blowby with the military rings from abuse (getting hot) or not seating well. It's not worth the money to go 0.x over on GM cast blocks. Deglaze, ignore everything but show stopper condition of cylinders otherwise, new rings and off you go.

Money is best spent looking for cracks in the heads, main webs, and cylinders.

Head studs are another good option since you are there.

BIGR

Lucky To Be Here

The square body 1980's Chevy Trucks bring back a lot of memories of a time when I was a lot younger.

I was at Tractor Supply yesterday, I saw a young man that had one, it was jacked up in the air, a 4x4, I thought you go guy.

I was at Tractor Supply yesterday, I saw a young man that had one, it was jacked up in the air, a 4x4, I thought you go guy.

Yeah, I thought about buying something else.(cummins) but I like this truck.

You can see how my Cumapart is working out for me...

btfarm

America First!

Welcome. I changed your picture to full size... LOVE square bodies

Husker6.5

135' diagonal 16:9HD, 25KW sound!

Spent a LOT of time behind the wheel of CUCV's back in the day. Always have a soft spot for the old square bodies.

Will L.

Well-Known Member

No matter what brand you choose, top post not side post.

As for brand, I am a optima fan. A bunch of stuff came out when they closed the US plant saying all the made in Mexico ones are junk. But I got over a decade on set from Mexico. The fleet I worked in that went to optimas for semi to pickups got massive years from them.

Search battery in the search section and you will find a few threads on it.

As for brand, I am a optima fan. A bunch of stuff came out when they closed the US plant saying all the made in Mexico ones are junk. But I got over a decade on set from Mexico. The fleet I worked in that went to optimas for semi to pickups got massive years from them.

Search battery in the search section and you will find a few threads on it.

If you go with AGM it is worthwhile to relocate them out of the engine heat. You get them for less corrosion.

In hot weather like we get combined with higher underhood temps of an IDI diesel the Optima red tops can't take it. I returned all I could and gave the last two away. The lifetime in gas rigs is also low in our heat but longer than diesels.

Spill proof is not leak proof. I have had Coroded cables and battery pan from side post leaking. Several cracked and leaked around top posts.

Even without the heat when I lived in normal climates like Colorado the luck I have had with them isn't as good as they used to be as far as longer life.

Deka agm's are worse in the heat. Swelling the case and failing open internally. Didn't last a year.

In hot weather like we get combined with higher underhood temps of an IDI diesel the Optima red tops can't take it. I returned all I could and gave the last two away. The lifetime in gas rigs is also low in our heat but longer than diesels.

Spill proof is not leak proof. I have had Coroded cables and battery pan from side post leaking. Several cracked and leaked around top posts.

Even without the heat when I lived in normal climates like Colorado the luck I have had with them isn't as good as they used to be as far as longer life.

Deka agm's are worse in the heat. Swelling the case and failing open internally. Didn't last a year.

Attachments

I would change the pre cups to diamond's for sure... and with the 88 6.2 heads I'm almost sure you would want 6.2 head gaskets NOT 6.5's.... I can't remember right now but older 6.2 heads have a different end water port and require a different gasket.... research before purchase to make sure the right gasket is used or you will end up with a leak...

I have been running 6.5 head gaskets on 1985 6.2 repowers without issue. 6.5 gaskets have been recommended for turbo 6.2's forever. Maybe you are thinking of the one off 1982?

Precups from NA engines limit your fuel with turbos. They are restrictive and spin the fuel air so fast that they centrifugally separate turning into smoke. This is Not an issue with GMx asthma attack turbos. Go bigger and precups hold you back.

6.2 heads have a different injector angle. This angle causes the injectors to hit the turbo manifold. Use two manifold gaskets to clear. Wrap manifold to keep heat down.

There was discussion of 6.2 precups having a different diameter than 6.5 precups so its not a drop in solution.

End of the day on a budget use 6.2 heads. Want power and big turbo the 6.2 heads are a problem esp. with precups. Good luck machining them, 6.2 NA, larger.

Precups from NA engines limit your fuel with turbos. They are restrictive and spin the fuel air so fast that they centrifugally separate turning into smoke. This is Not an issue with GMx asthma attack turbos. Go bigger and precups hold you back.

6.2 heads have a different injector angle. This angle causes the injectors to hit the turbo manifold. Use two manifold gaskets to clear. Wrap manifold to keep heat down.

There was discussion of 6.2 precups having a different diameter than 6.5 precups so its not a drop in solution.

End of the day on a budget use 6.2 heads. Want power and big turbo the 6.2 heads are a problem esp. with precups. Good luck machining them, 6.2 NA, larger.

Will L.

Well-Known Member

You can machine the precups to work, but have to call around to shops that grind inconel. More and more shops can do it now with better machinery becoming more affordable and almost everything cnc.

I was thinking there was 6.2 head that used different size precup than the other 6.2s - same size as the 6.5, but can’t remember details.

Plan on maching work. Imo, definitely do the better precups.

Many people accredited the smaller precups in n/a 6.2 heads to the higher mpg’s of old. The testing we did at the fuel company proved this incorrect. It was the old fuel that is no longer produced. We had a 100,000 gallon batch produced for testing. My 99 pickup went up 4.5 hiway mpg from just the fuel alone. But of course it killed 8.4 million penguins and raised Earths temperature 18 degrees doing so. Ok, so I bumped the numbers a little- it was 4.47 or 4.48 - close enough. Haha.

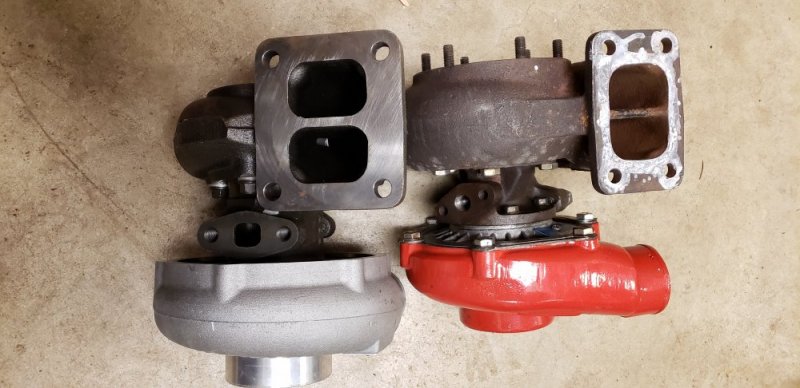

Hoping one of the turbo gurus could tell you something about your turbos there. Especially @Twisted Steel Performance or @WarWagon as they are usually outspoken quite well on thier favorite turbos in this platform. I just feel GM’s suck as much as they blow.

I was thinking there was 6.2 head that used different size precup than the other 6.2s - same size as the 6.5, but can’t remember details.

Plan on maching work. Imo, definitely do the better precups.

Many people accredited the smaller precups in n/a 6.2 heads to the higher mpg’s of old. The testing we did at the fuel company proved this incorrect. It was the old fuel that is no longer produced. We had a 100,000 gallon batch produced for testing. My 99 pickup went up 4.5 hiway mpg from just the fuel alone. But of course it killed 8.4 million penguins and raised Earths temperature 18 degrees doing so. Ok, so I bumped the numbers a little- it was 4.47 or 4.48 - close enough. Haha.

Hoping one of the turbo gurus could tell you something about your turbos there. Especially @Twisted Steel Performance or @WarWagon as they are usually outspoken quite well on thier favorite turbos in this platform. I just feel GM’s suck as much as they blow.