Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

-

Welcome to The Truck Stop! We see you haven't REGISTERED yet.

Your truck knowledge is missing!

- Registration is FREE , all we need is your birthday and email. (We don't share ANY data with ANYONE)

- We have tons of knowledge here for your diesel truck!

- Post your own topics and reply to existing threads to help others out!

- NO ADS! The site is fully functional and ad free!

Problems registering? Click here to contact us!

Already registered, but need a PASSWORD RESET? CLICK HERE TO RESET YOUR PASSWORD!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

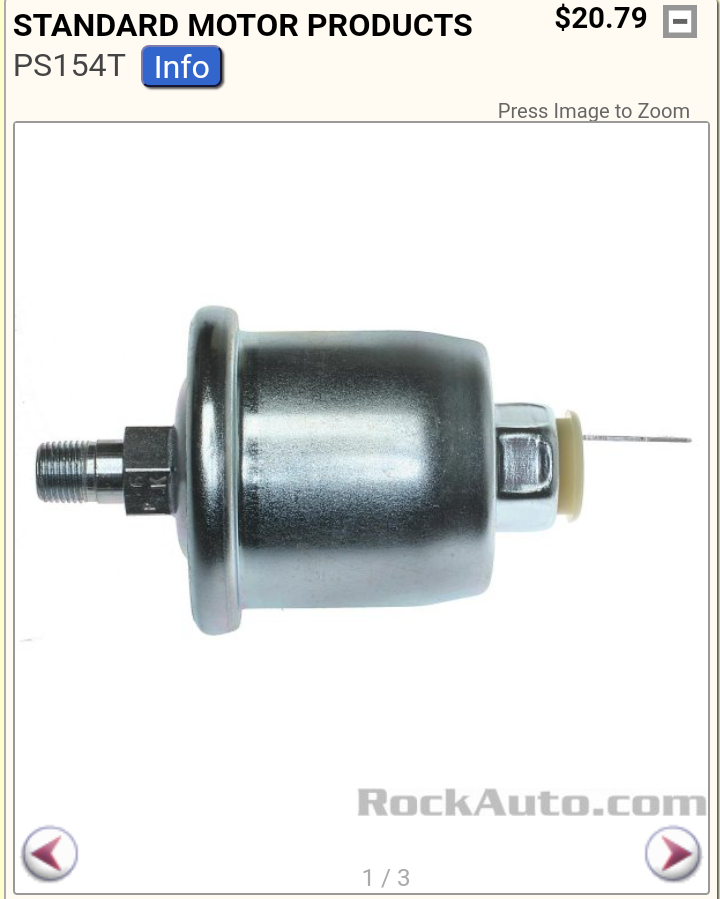

Oil pressure sender

- Thread starter dixiepc

- Start date

ak diesel driver

6.5 driver

Why does the switch matter?

MrMarty51

Well-Known Member

Use the 6.5 switched sender, just clip the wire(s) for the switch.

Even if the switch side fails, the sender side will continue on in its duties.

Even if the switch side fails, the sender side will continue on in its duties.

MrMarty51

Well-Known Member

But why mess with the terminal end when it would be totally unnecessary ?

Will L.

Well-Known Member

The reason the newer ones burn out more frequently is the excessive load from the lift pump on it. Adding a relay eliminates the problem. If you are just using it for the pressure- it will last a really long time. Being smaller and more readily available- Just stick with it imo.

if you need OP sensor only....you must go over aftermarket spare part sensor

this is my part spare for fuel pressure sensor

it has stainless steel housing .... you can choise bolt tread, pressure range or Ohm range

whatever you need, it doesn't cost a fortune

when bought it, 3-4 years ago about $18/20 from china

this is my part spare for fuel pressure sensor

it has stainless steel housing .... you can choise bolt tread, pressure range or Ohm range

whatever you need, it doesn't cost a fortune

when bought it, 3-4 years ago about $18/20 from china

Attachments

you must measure your old oil pressure sender if it is in good shape....

but if you don't know how to measure Ohm ... I think it's better for you get help from someone. also to not short the sensor when you connect it.

OIL PRESSURE GAGE

The engine oil pressure is displayed by the Oil

Pressure Gage. The pointer of the Gage is moved by two

coils, and its operation is similar to that of the Fuel Gage.

The Oil Pressure Sender is connected to the junction of

the two coils. It has low resistance when the oil pressure is

low, and high ohms resistance when the oil pressure is

high. This changing resistance changes the current flow

through the coils. The magnetic fields of the coils move the

pointer from low to high.

connect the sensor to an air compressor, low pressure line with pressure tap and gauge and increase the pressure da 0 psi to 80psi meanwhile you measure with a multimeter the output signal from sender to gauge ....use a battery to power the sensor, it has 3 wire positive inlet, positive outlet, and signal to the gauge, negative pole is the sensor mass...

see pdf Attachment

but if you don't know how to measure Ohm ... I think it's better for you get help from someone. also to not short the sensor when you connect it.

OIL PRESSURE GAGE

The engine oil pressure is displayed by the Oil

Pressure Gage. The pointer of the Gage is moved by two

coils, and its operation is similar to that of the Fuel Gage.

The Oil Pressure Sender is connected to the junction of

the two coils. It has low resistance when the oil pressure is

low, and high ohms resistance when the oil pressure is

high. This changing resistance changes the current flow

through the coils. The magnetic fields of the coils move the

pointer from low to high.

connect the sensor to an air compressor, low pressure line with pressure tap and gauge and increase the pressure da 0 psi to 80psi meanwhile you measure with a multimeter the output signal from sender to gauge ....use a battery to power the sensor, it has 3 wire positive inlet, positive outlet, and signal to the gauge, negative pole is the sensor mass...

see pdf Attachment

![20230217_111651[1].jpg](/forum/data/attachments/67/67864-9bfad4b7bf8fc052bf52c854b6c0939c.jpg)