Newguy1998

Member

Hi there, first time posting, fairly familiar with 6.5's, had one for quite a while

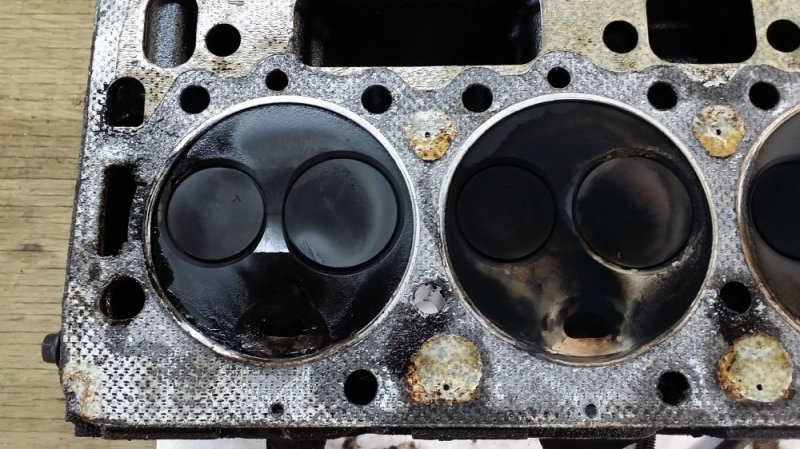

I could use some help verifying my blown head gaskets, and a few questions about replacing them

I was going to pull the coolant crossover and start the engine let it run without the belt on. I understand this is a way to see bubbles coming from one side of the heads or the other. Will this work? If not, any suggestions?

Also once I strip the engine down to the heads and pull the heads off, is it just as simple as replacing the gaskets and putting the heads and Rockers back on? With new bolts of course. I downloaded a service manual. And in it it says you need to have the crank at a certain position so the valves don't touch the Pistons. Does this still need to be done while replacing the gaskets? Seeing that the valves are already timed.

Thanks in advance for anything you can add.

I could use some help verifying my blown head gaskets, and a few questions about replacing them

I was going to pull the coolant crossover and start the engine let it run without the belt on. I understand this is a way to see bubbles coming from one side of the heads or the other. Will this work? If not, any suggestions?

Also once I strip the engine down to the heads and pull the heads off, is it just as simple as replacing the gaskets and putting the heads and Rockers back on? With new bolts of course. I downloaded a service manual. And in it it says you need to have the crank at a certain position so the valves don't touch the Pistons. Does this still need to be done while replacing the gaskets? Seeing that the valves are already timed.

Thanks in advance for anything you can add.