red

Being a lake bum in Texas

Well finally picked up a 6.5 yesterday for my truck, hopeing to install it in the next 2 months.

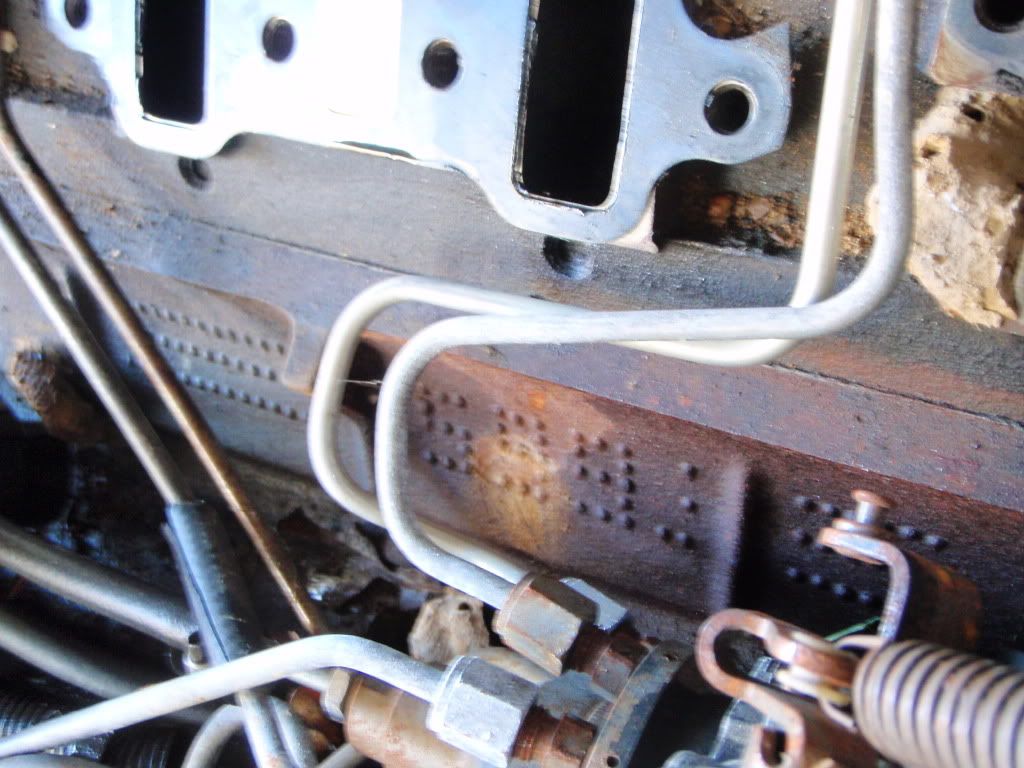

For those of you who have not been following this truck and the issues I've been having heres the rundown. It's a 1987 chevy crew cab long bed (9 foot flatbed) dually on a 6" lift and 35" tires that I use on medium difficulty offroad trails and for towing. When i bought the truck it had a good running 454 backed by a sm465 and np205. After alot of research I had decided to convert it to a 12 valve cummins, nv4500 and np205 with engine goodies. Got the engine and trans in after months of fighting with discontinued parts that people wanted fortunes for, and finally had enough of that when it came to the tcase so pulled that drivetrain back out and sold it. Was wanting to drive my truck again (had been 5 months) so i decided the cheapest and easiest route would be to go back to a big block gasser. Sadly about this time I no longer had a shop to work in so I had to drop the truck off at a mechanics shop. Fast forward through the issues there it took me 7 months to get my truck back :cussing: and it had alot of issues from their install. Fuel lines ran incorrectly (somehow got the mechanical fuel pump to work off of its return line and had capped the main line), clutch throwout bearing was installed incorrectly, brand new hydroboost pump squeals, engine has an oil leak, and the starter grenaded (that made 14 for this engine block since i've had it, thank god for free replacement warranties).

After I fixed their mistakes I broke the motor in, changed its fluids, and made the trip from northern Utah back to west Texas since my military enlistment is now over, going to work oilfield. Motor pulls wonderfully, just cant pass a gas station to save its life haha. Gets 7-8mpg cruising at 60-65mph (2250-2500rpm). Motor has been bored 30 over, exhaust valves enlarged, dual plane intake manifold, 750cfm carb, long tube headers, and a custom cam for torque in the low-mid range.

Back on topic, that kind of fuel economy on the highway makes this thing prohibitive to drive since most of its driving is long distance highway. I decided to go with a built 6.5 because of the simplicity of the conversion, and the cost factor.

Thanks to deejaa I now have a 6.5 that was installed in a 92 c3500hd. motor was a crate engine that was installed in 2004 so i'm curious if its a new block, will hopefully find out today. has a mechanical injection pump, 130-140k miles on the engine, and as it sits right now fires right up and sounds healthy.

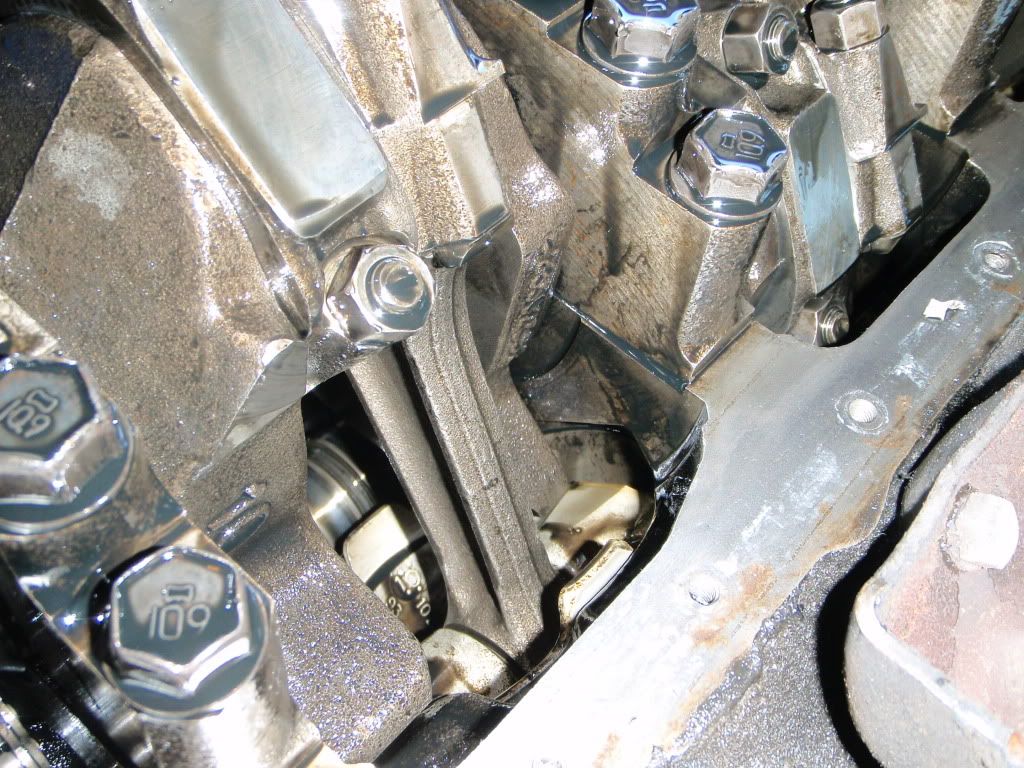

Today I will be draining the oil, putting the motor on a stand and pulling the pan to inspect the mains. Does anyone have the part#s for the main studs? Thinking of running a stud girdle as well, any other upgrades to run on the bottom end? The goal for the motor is to be in the 500-600ft/lbs range reliably (I know pushing the motor).

Current plans for the motor consist of:

1. Main studs

2. stud girdle

3. Lowering compression to 19 or 20:1, not with head gaskets

4. diamond precups or just enlarging the ones that it has

5. Head studs

6. ATT turbo

7. Intercooler, I have one that is already modified to fit from when the cummins was going in

8. 2.5" crossover and either a 3 or 4" downpipe. Problem here is getting the exhaust to clear my t-case since the truck is a passenger side drop t-case.

9. high flow waterpump

10. Dmax fan

11. Dual t-stat housing

Debating whether to run the stock manifolds which might run into my ac box or possibly build custom ones that will flow better. The truck has a high clearance engine crossmember from off road design that moves the engine 3" forward and up 2"

For those of you who have not been following this truck and the issues I've been having heres the rundown. It's a 1987 chevy crew cab long bed (9 foot flatbed) dually on a 6" lift and 35" tires that I use on medium difficulty offroad trails and for towing. When i bought the truck it had a good running 454 backed by a sm465 and np205. After alot of research I had decided to convert it to a 12 valve cummins, nv4500 and np205 with engine goodies. Got the engine and trans in after months of fighting with discontinued parts that people wanted fortunes for, and finally had enough of that when it came to the tcase so pulled that drivetrain back out and sold it. Was wanting to drive my truck again (had been 5 months) so i decided the cheapest and easiest route would be to go back to a big block gasser. Sadly about this time I no longer had a shop to work in so I had to drop the truck off at a mechanics shop. Fast forward through the issues there it took me 7 months to get my truck back :cussing: and it had alot of issues from their install. Fuel lines ran incorrectly (somehow got the mechanical fuel pump to work off of its return line and had capped the main line), clutch throwout bearing was installed incorrectly, brand new hydroboost pump squeals, engine has an oil leak, and the starter grenaded (that made 14 for this engine block since i've had it, thank god for free replacement warranties).

After I fixed their mistakes I broke the motor in, changed its fluids, and made the trip from northern Utah back to west Texas since my military enlistment is now over, going to work oilfield. Motor pulls wonderfully, just cant pass a gas station to save its life haha. Gets 7-8mpg cruising at 60-65mph (2250-2500rpm). Motor has been bored 30 over, exhaust valves enlarged, dual plane intake manifold, 750cfm carb, long tube headers, and a custom cam for torque in the low-mid range.

Back on topic, that kind of fuel economy on the highway makes this thing prohibitive to drive since most of its driving is long distance highway. I decided to go with a built 6.5 because of the simplicity of the conversion, and the cost factor.

Thanks to deejaa I now have a 6.5 that was installed in a 92 c3500hd. motor was a crate engine that was installed in 2004 so i'm curious if its a new block, will hopefully find out today. has a mechanical injection pump, 130-140k miles on the engine, and as it sits right now fires right up and sounds healthy.

Today I will be draining the oil, putting the motor on a stand and pulling the pan to inspect the mains. Does anyone have the part#s for the main studs? Thinking of running a stud girdle as well, any other upgrades to run on the bottom end? The goal for the motor is to be in the 500-600ft/lbs range reliably (I know pushing the motor).

Current plans for the motor consist of:

1. Main studs

2. stud girdle

3. Lowering compression to 19 or 20:1, not with head gaskets

4. diamond precups or just enlarging the ones that it has

5. Head studs

6. ATT turbo

7. Intercooler, I have one that is already modified to fit from when the cummins was going in

8. 2.5" crossover and either a 3 or 4" downpipe. Problem here is getting the exhaust to clear my t-case since the truck is a passenger side drop t-case.

9. high flow waterpump

10. Dmax fan

11. Dual t-stat housing

Debating whether to run the stock manifolds which might run into my ac box or possibly build custom ones that will flow better. The truck has a high clearance engine crossmember from off road design that moves the engine 3" forward and up 2"