JiFaire

Land Mine Finder

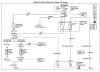

In OBD-IIs, with OPS unplugged lift will continue to run, been there done that just test the theory if it's really needed or not, test condutcted at GMCTD's place both of us learing the ins & outs of the lift powering routine of a OBD-II, unplugged the PCM feed lift still runs, unplug both or the common gnd and lift loses power.

See, here's where my theory kicks in... if the OPS is plugged in, but dead, will power flow through that side? When the contacts fry in aftermarket OPS modules, this seems to keep coming up. Along with blown fuses, on occasion.

Sure would be nice to get a good handle on this - I know they are SUPPOSED to be ECM-controlled, but then, why are they (OPS) still there? Too many anomalies...