OPS port leaking oil?

Fuel leak can also let air in so its possible.

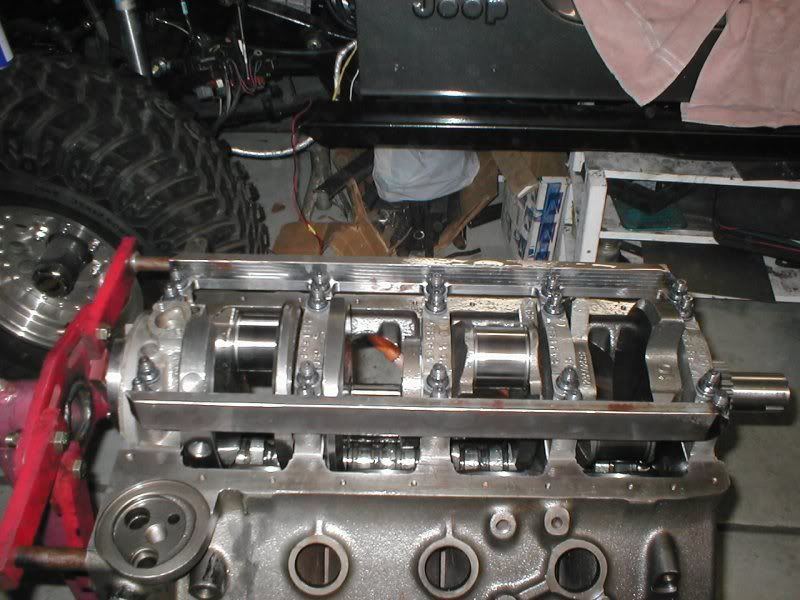

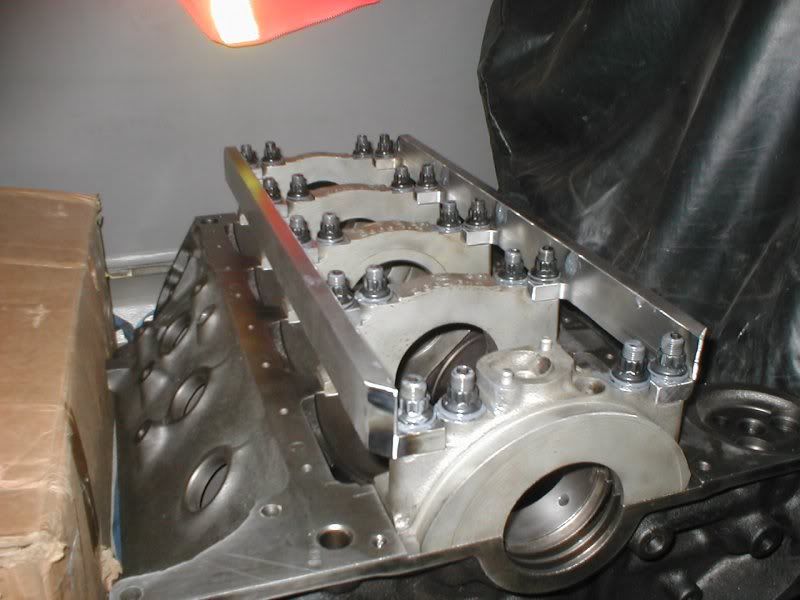

I'm in procees of build an engine now, where did you get the roller rockers?

Fuel leak can also let air in so its possible.

I'm in procees of build an engine now, where did you get the roller rockers?