LyleD

New Member

- Messages

- 4

- Reaction score

- 9

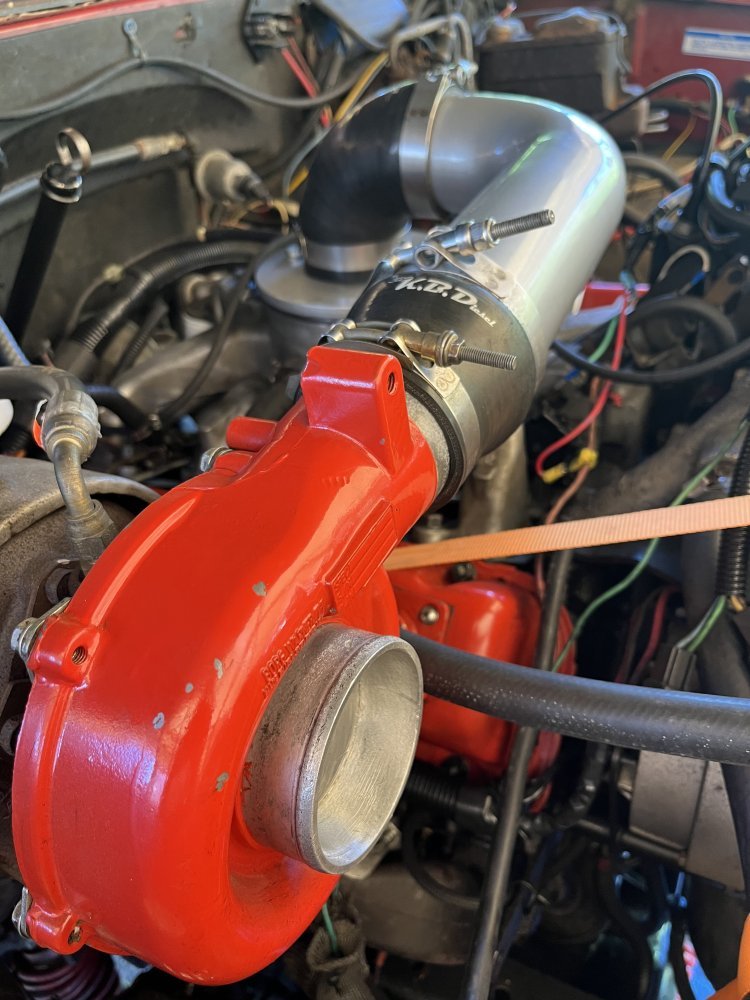

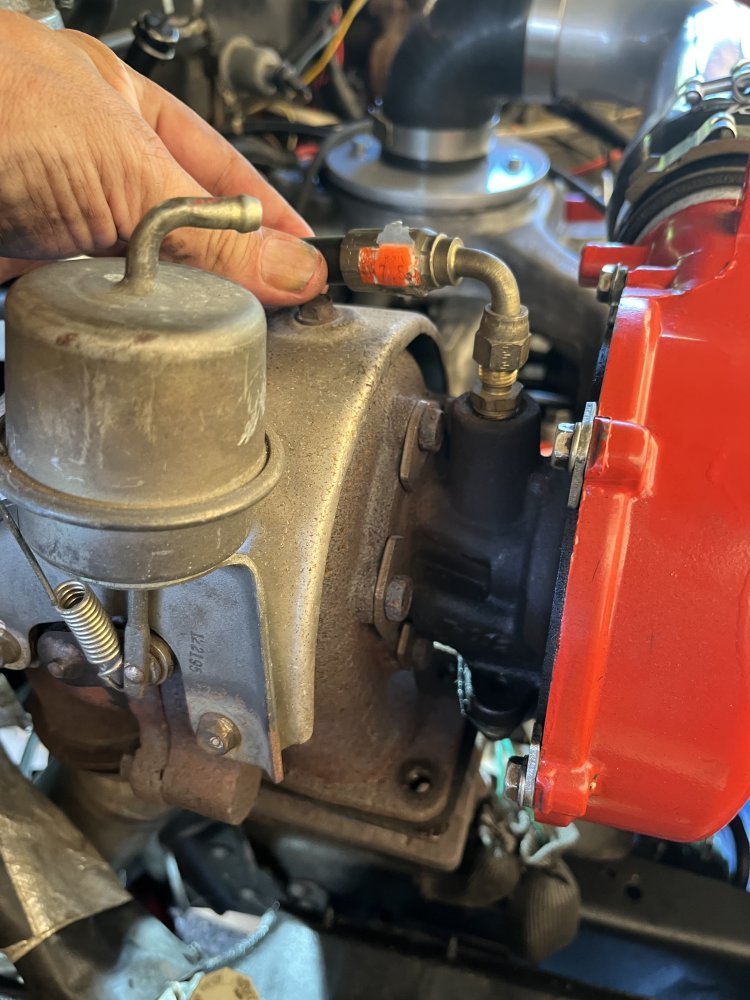

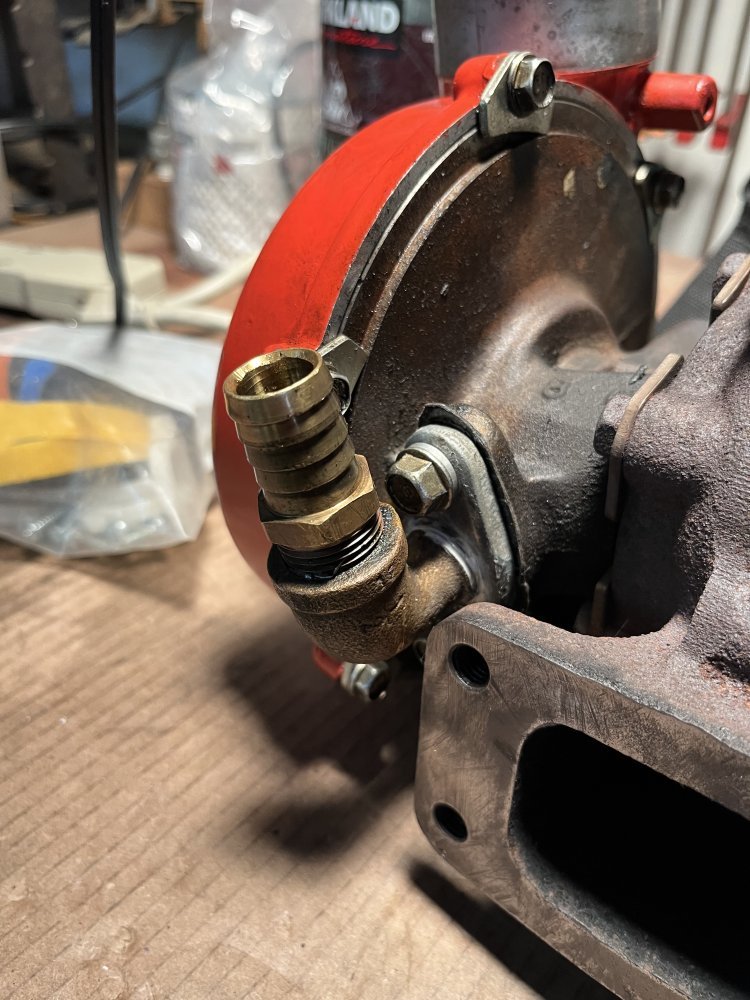

Hi, my name is Lyle and I discovered this forum as I have an 83 GMC that I have recently purchased and been working on. Currently, while replacing a fuel injector, I happened to look in the pipe that runs from the turbo to the intake and saw a small pool of oil. Now I am wondering if I need to rebuild the turbo!

This looks like a friendly and highly informational forum. I am looking forward to learning and participating/contributing here!

This looks like a friendly and highly informational forum. I am looking forward to learning and participating/contributing here!