Mark towery

Member

- Messages

- 49

- Reaction score

- 87

I have a 2000 6.5 turbo k3500

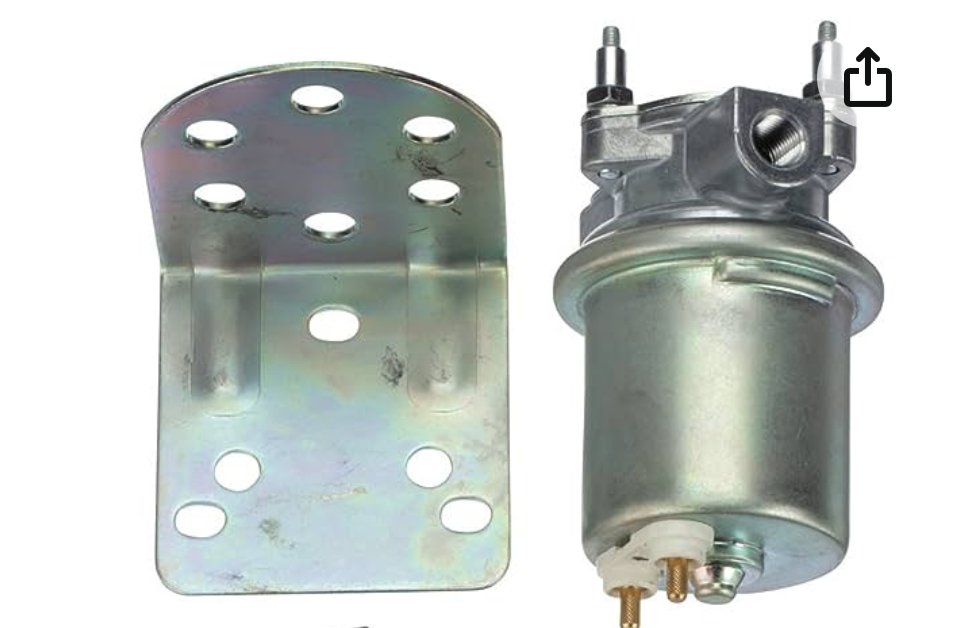

It accelerates good but when I start easing out of I try it cuts out. And after I driver it and let it set for a few minutes it has a hard time starting. I have changed ops, pmd,fuel filter and cleaned sock in fuel tank. My lift pump turns on and has 4 pounds of pressure

It accelerates good but when I start easing out of I try it cuts out. And after I driver it and let it set for a few minutes it has a hard time starting. I have changed ops, pmd,fuel filter and cleaned sock in fuel tank. My lift pump turns on and has 4 pounds of pressure