panran

Well-Known Member

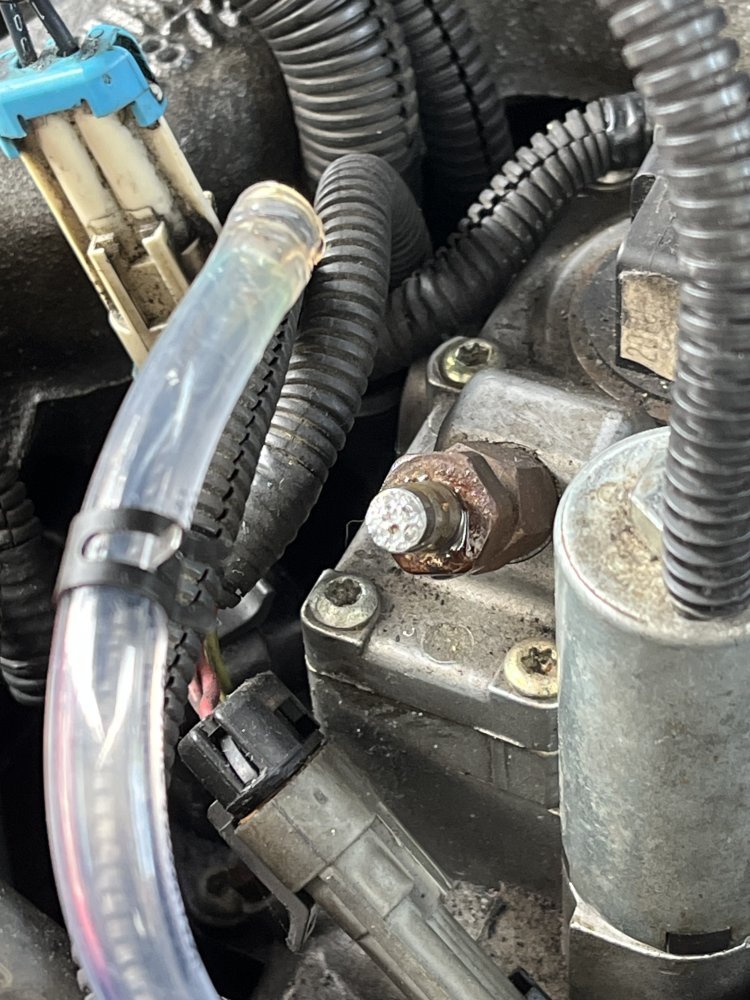

Okay, so sometimes I’m dense, do I unscrew it and leave it plugged in and try to start it…when I screw it in I think I will have to unplug it and if it keeps running is that like a runaway and I should take a pliers to the return line?