mhixson

Member

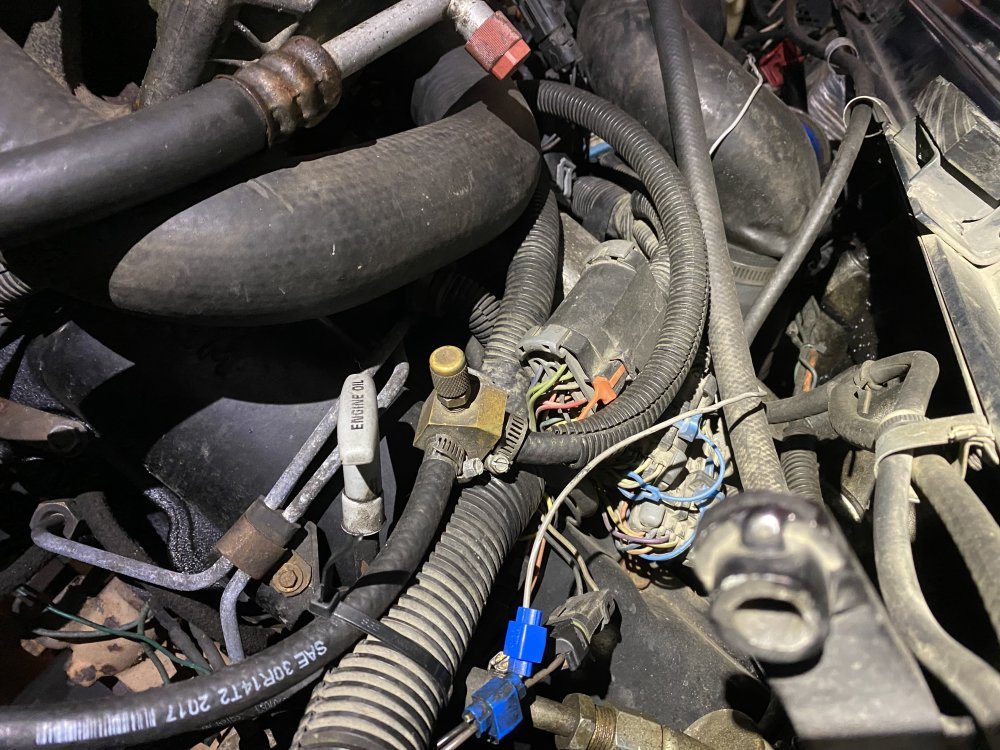

Noticed recently that my truck (1996 AM General Hummer with GM 6.5 TD) would sporadically rev its engine just a bit while idling. Took it for a spin and once while slowing down from 50MPH or so to take a turn the engine revved while I was off the throttle. I've had a failing crank position sensor before and this doesn't feel the same. In that failure it was like the truck was abruptly downshifting and didn't know what gear it wanted to be in. This just seems like I'm tapping the accelerator when I'm not.

I've only noticed it while decelerating, coasting downhill, or idling at stop. I haven't noticed it when on the throttle while accelerating or climbing my steep driveway.

I just replaced my PMD with a new Standadyne and used the same resistor that was in my old one. Same exact symptom persisted. My air filter looks reasonably clean and I also replaced the fuel filter. The old one was pretty dirty.

Two codes I have now are

P1214

P1218

Any help or diagnostic suggestions would be greatly appreciated.

I've only noticed it while decelerating, coasting downhill, or idling at stop. I haven't noticed it when on the throttle while accelerating or climbing my steep driveway.

I just replaced my PMD with a new Standadyne and used the same resistor that was in my old one. Same exact symptom persisted. My air filter looks reasonably clean and I also replaced the fuel filter. The old one was pretty dirty.

Two codes I have now are

P1214

P1218

Any help or diagnostic suggestions would be greatly appreciated.