schiker

Well-Known Member

I am changing the hydraulic filter on neighbor's CTL and the filter is stuck. I am suspecting I am doing something wrong. Does hydraulic system pressure need to be bled or relieved first?

How would I do this? Lower arms/bucket then pull trigger on joystick to float bucket? Do I need to plug something into aux lines? Any other thing to do?

With new machines when you cut off the machines the hydraulics lock and goes into park. Does this cause hydraulics to lock down again????

---------

I used a C hook spanner and it seemed to grip the filter good and it didn't budge trying it. So I put a cheater on it and it stripped off the only tooth I can get the spanner onto so its dang tight.

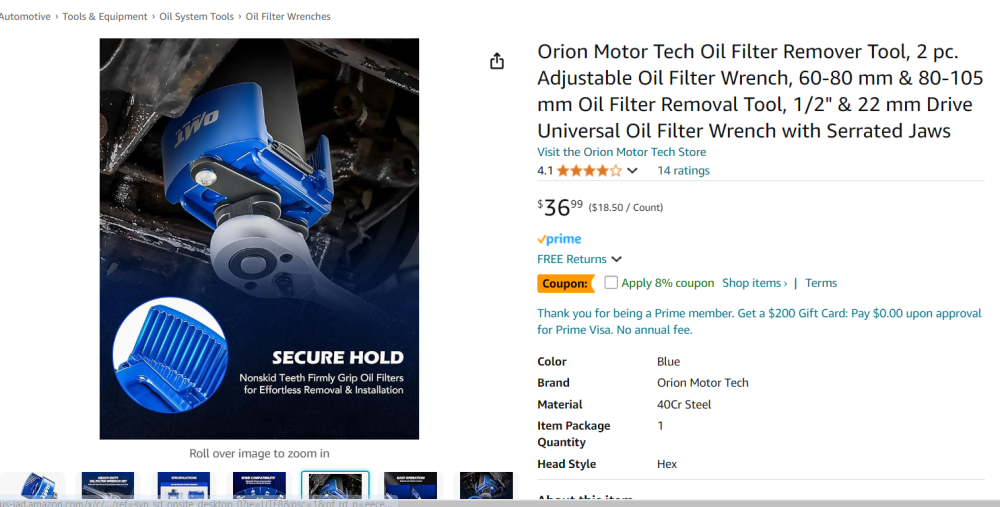

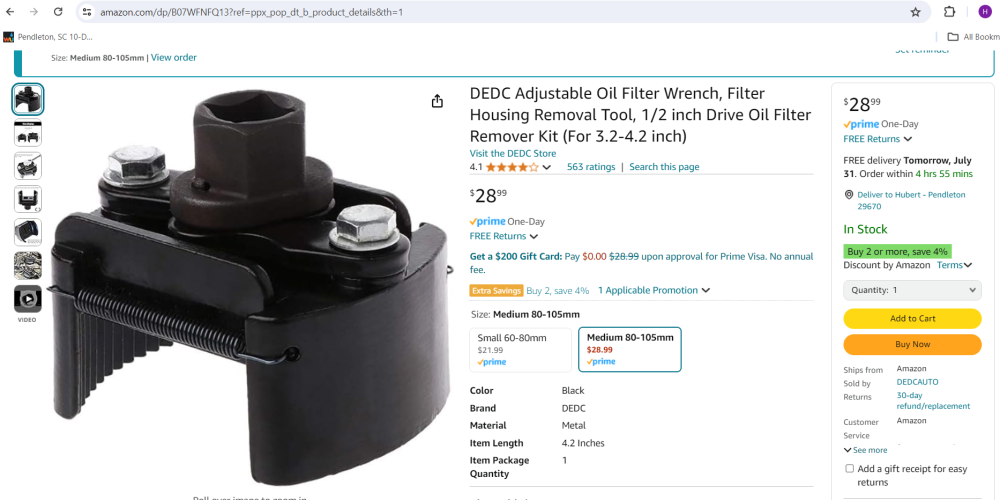

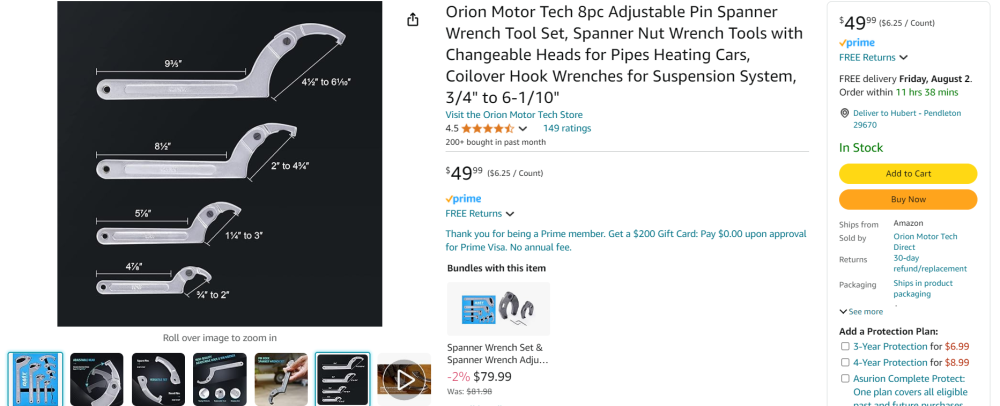

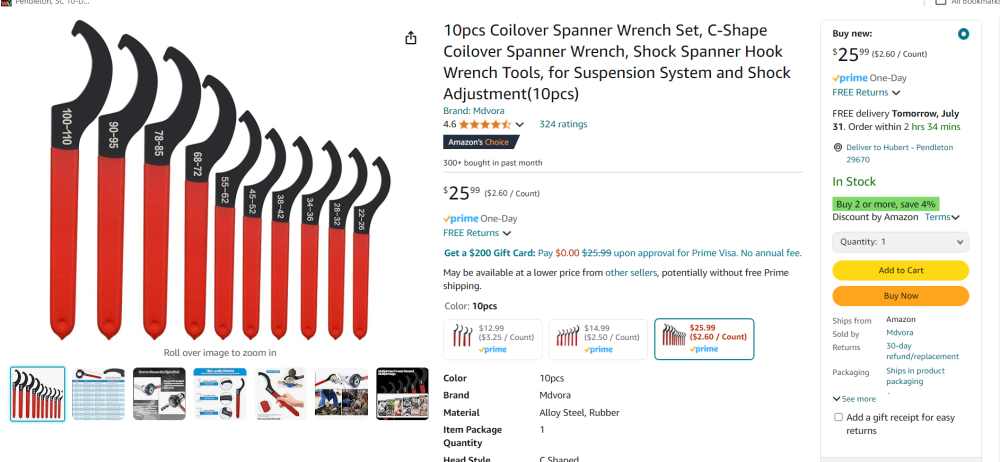

I am going to order a new C hook adjustable style spanner that I hope to be able to get to another notch. Also, going to try either a chain wrench or strap wrench too to add more torque.

I have thought about wrapping the filter with friction tape then using a couple of hose clamps to tighten down to make a tooth for the new spanner wrench. OR use the hose clamps to be able to hit a drift to help loosen it while using strap wrenches. The notches in the filter don't leave much access for a helper to be able to hit them at at a good angle.

Suggestions? Looking online I see suggestions for end cap filter wrenches that are suppose to grip well. Brand suggestions?

How would I do this? Lower arms/bucket then pull trigger on joystick to float bucket? Do I need to plug something into aux lines? Any other thing to do?

With new machines when you cut off the machines the hydraulics lock and goes into park. Does this cause hydraulics to lock down again????

---------

I used a C hook spanner and it seemed to grip the filter good and it didn't budge trying it. So I put a cheater on it and it stripped off the only tooth I can get the spanner onto so its dang tight.

I am going to order a new C hook adjustable style spanner that I hope to be able to get to another notch. Also, going to try either a chain wrench or strap wrench too to add more torque.

I have thought about wrapping the filter with friction tape then using a couple of hose clamps to tighten down to make a tooth for the new spanner wrench. OR use the hose clamps to be able to hit a drift to help loosen it while using strap wrenches. The notches in the filter don't leave much access for a helper to be able to hit them at at a good angle.

Suggestions? Looking online I see suggestions for end cap filter wrenches that are suppose to grip well. Brand suggestions?