BigBlueChevy

Compression Ignition Addict

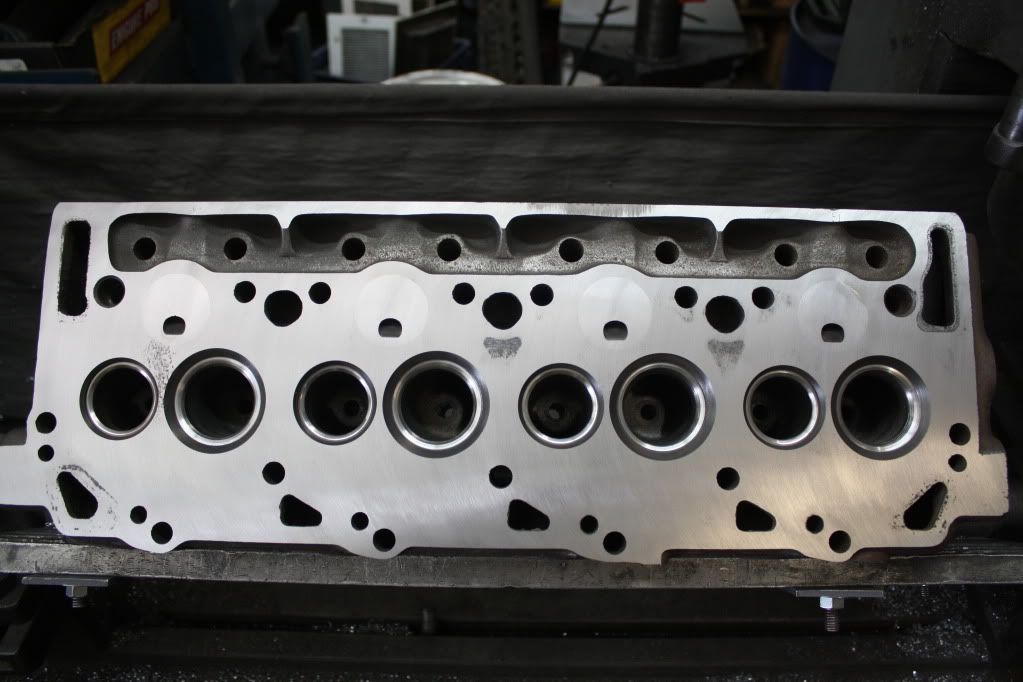

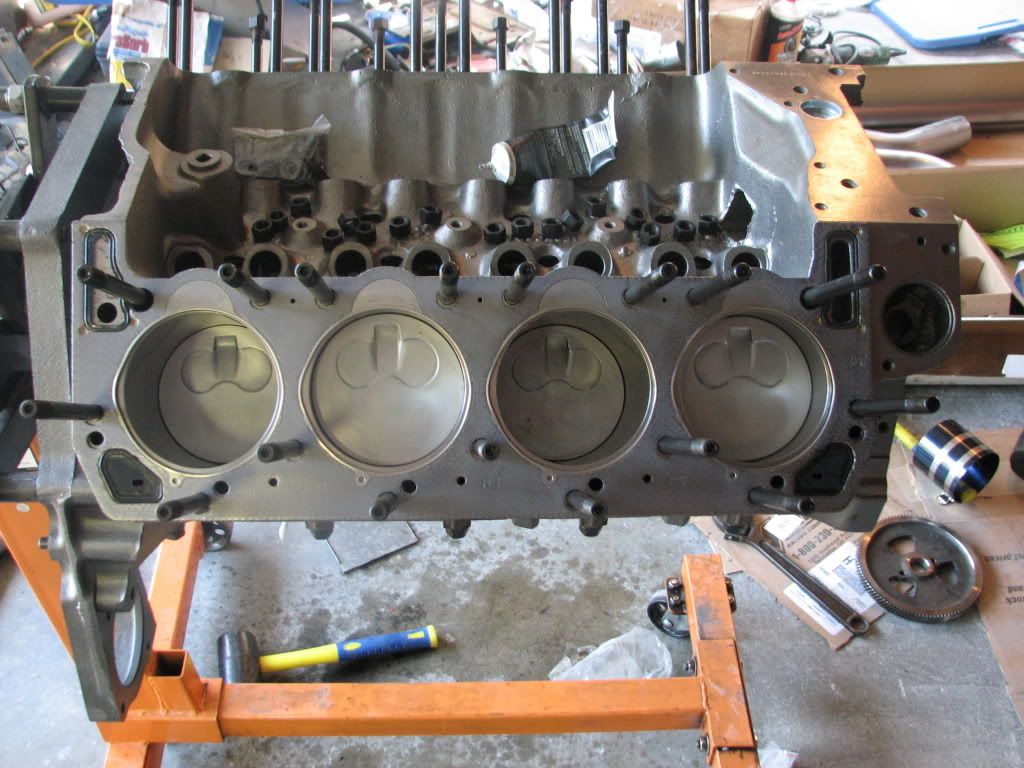

I think the reason that the 6.5L has trouble making up in the torque department has to do with a variety of little things. The biggest being the precups. They are a huge limiting factor in getting the flame front and explosive force at TDC compression to get to the piston. That small opening that opens up to the cylinder bore is rather restrictive in comparison to a direct injection. Then factor in things such as timing, available fuel, higher IAT due to the lack of a CAC, compression ratio's, and Bore / stroke. Its a variety of things, but I really think there is amazing torque potential available if someone could find a way to take the precups out of the equation.