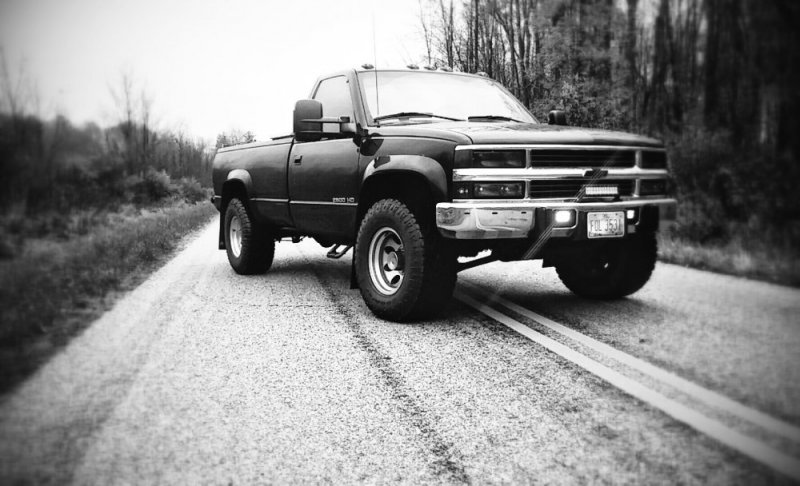

SethRoush97_6_5

New Member

Looking to add an AirDog 100 lift pump. The question I have is would it replace the stock size pump I have now or would it be an add on like guys do with fass fuel systems? I've also heard things about about being able to do away with the fuel bowl. Any help with this would be greatly appreciated. I know some of the things I wanna do might be pushing the limits on a 6.5, but it's no fun when you done break things from time to time