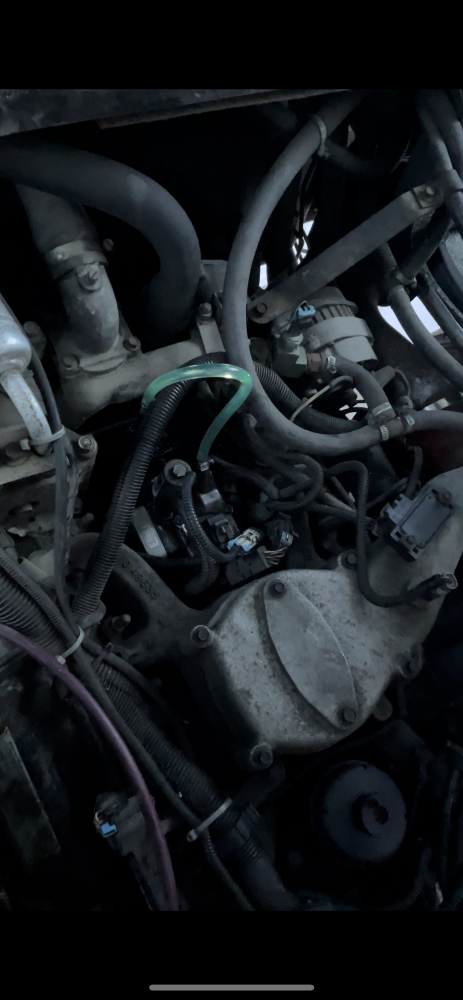

RV idles (smoothly) for 3 minutes, or 1min, or 10 seconds several times (then cuts off suddenly) during a cold start before finally running well for as long as needed, after several tries. Can that be related to air in fuel lines? Before I add clear hoses to watch for bubbles. Few questions:

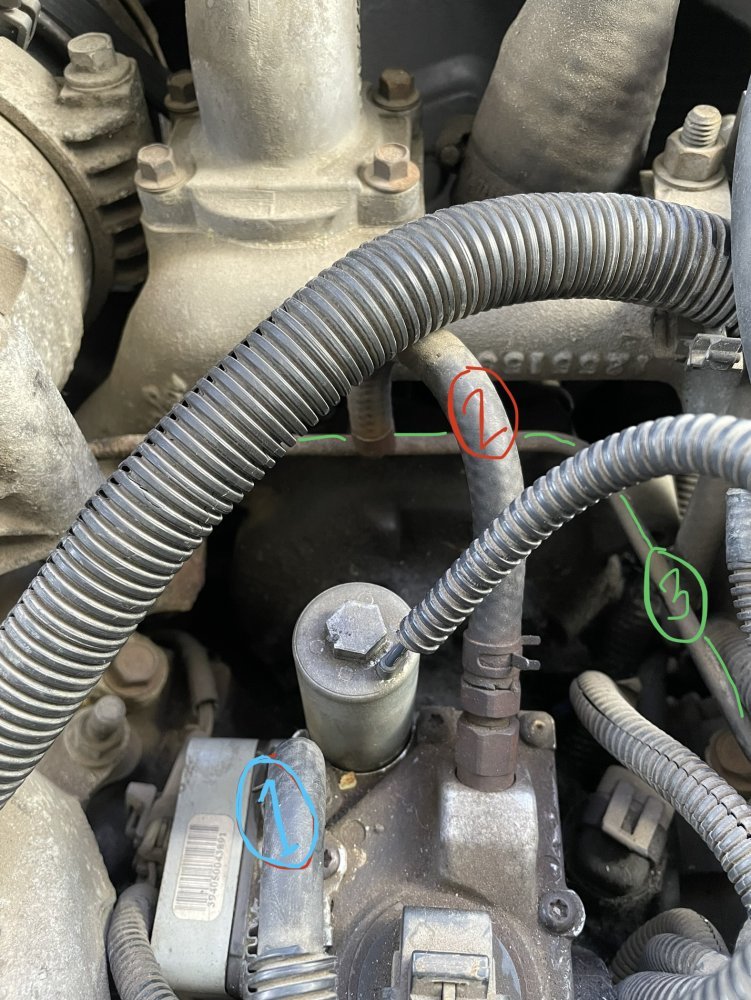

1. A clear fuel line at hose labeled (2) would show fuel going to hard line (3) and to the injectors? What the hose label (2) called?

2. The hose label (1), is that my return line?where does it go to. Replacing it would show me the fuel coming directly from where to the injection pump? Directly from the Fuel Filter Manager? Where can I follow it all the way to and replace it.

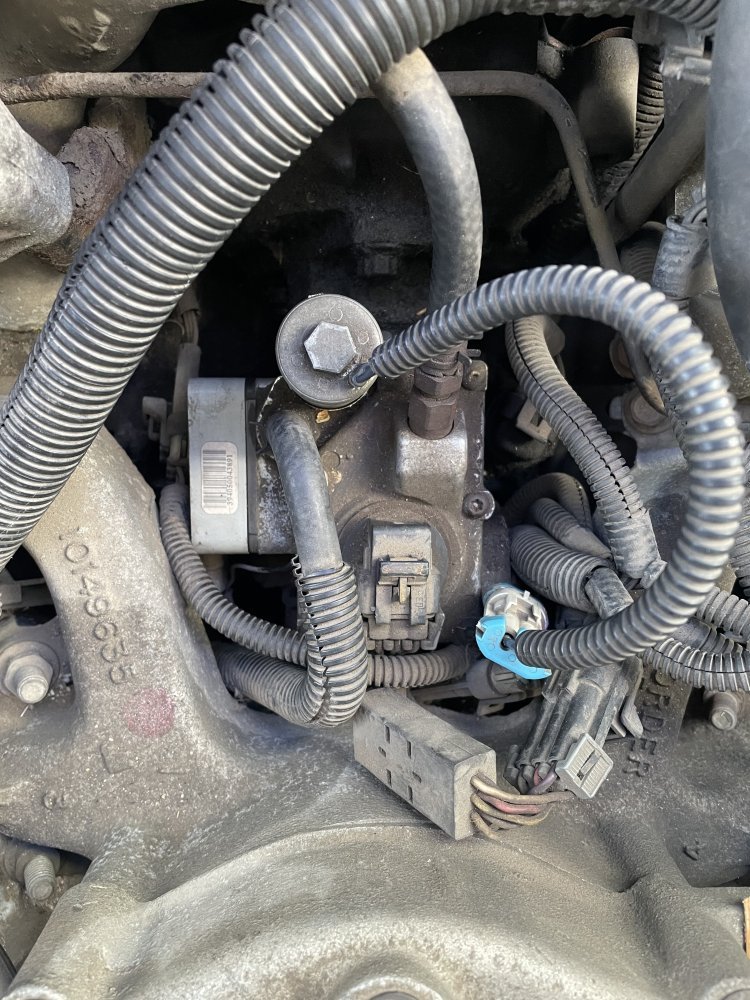

3. Will replacing the return lines between my injectors with clear ones to see any bubbles benefit me any in seeing if I have air in fuel?

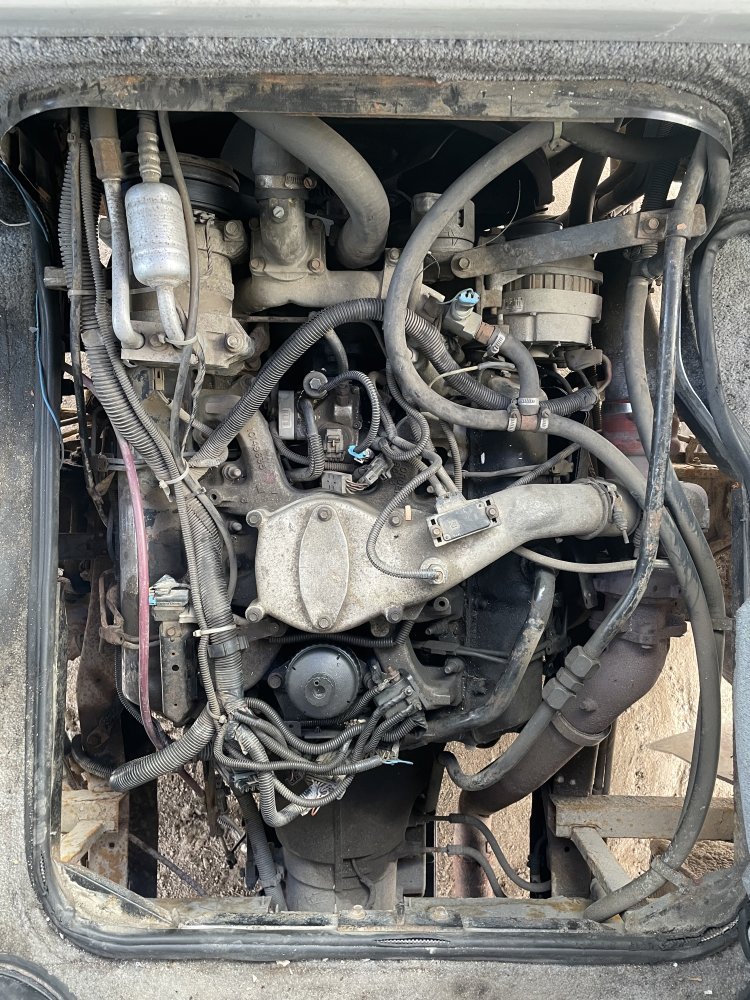

4. Do my fuel lines need to be heat rated. If I’m not mistaken one of them will go under the intake manifold into something else, isn’t it hot there? Where to get heat rated clear fuel lines.

1. A clear fuel line at hose labeled (2) would show fuel going to hard line (3) and to the injectors? What the hose label (2) called?

2. The hose label (1), is that my return line?where does it go to. Replacing it would show me the fuel coming directly from where to the injection pump? Directly from the Fuel Filter Manager? Where can I follow it all the way to and replace it.

3. Will replacing the return lines between my injectors with clear ones to see any bubbles benefit me any in seeing if I have air in fuel?

4. Do my fuel lines need to be heat rated. If I’m not mistaken one of them will go under the intake manifold into something else, isn’t it hot there? Where to get heat rated clear fuel lines.