83GMCK2500

Active Member

Disclaimer: It burns gasoline. :hihi:

As the title states:

1996 GMC Sierra Extended Cab 4x4 3500 Dual Rear Wheel - 196,### miles

Vortec 454

New Venture 4500 5-speed manual transmission

Borg Warner (something) floor shift transfer case (with this tcase and transmission combo the truck has 3 PTO provisions)

FACTORY 4.56 gears w/G80 in the rear

Chrome wheels that have been painted black

Dark Hunt Club Red Metallic exterior paint

Light smoke gray cloth interior, 60/40 split bench with lumbar on both sides.

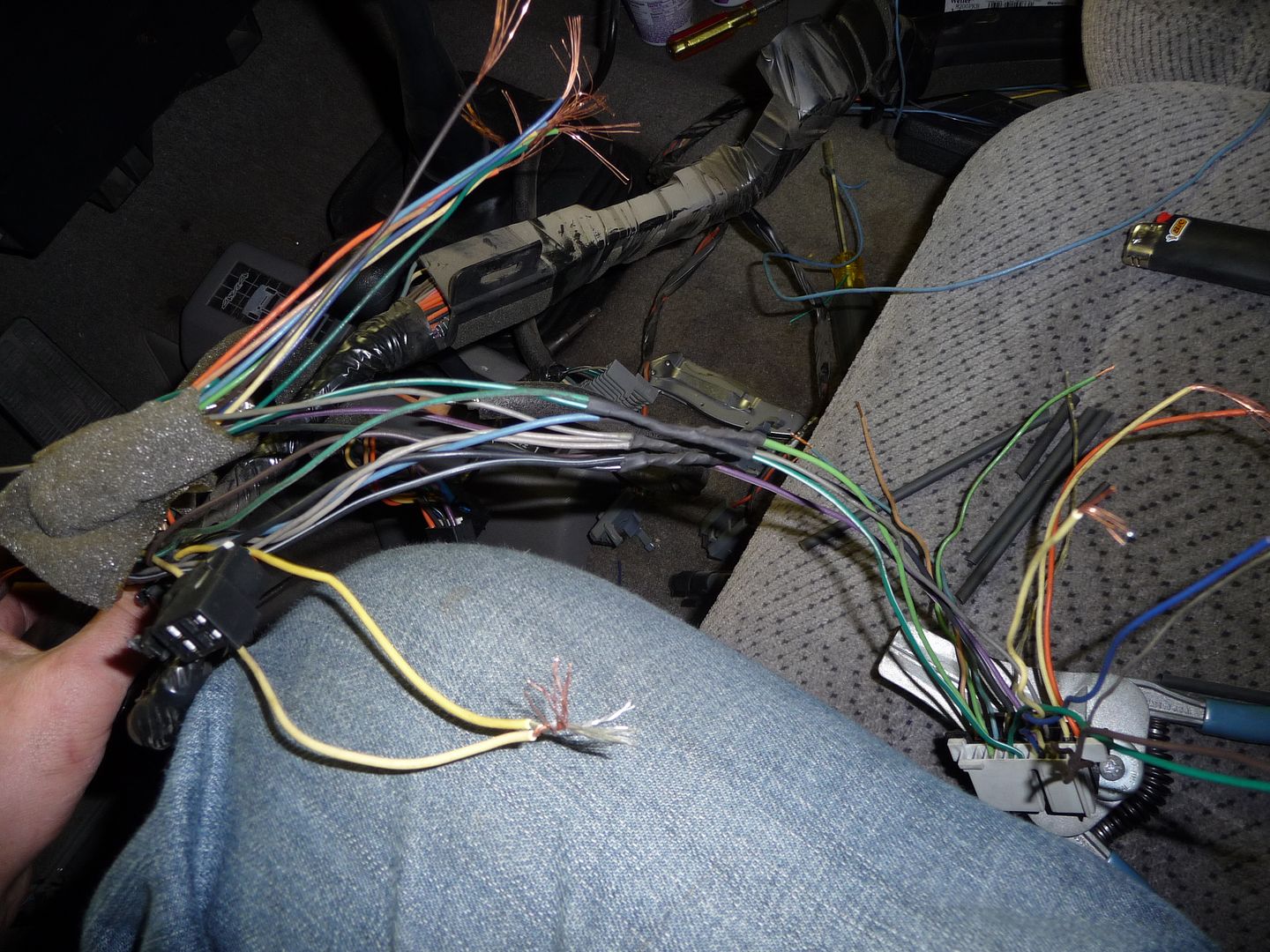

One atrocious analog radio that wasn't even connected, the pigtail had been hacked off.

Pictures from the day we looked at it and brought it home. Year should be 2011 from the camera, forgot that it had been reset.

As the title states:

1996 GMC Sierra Extended Cab 4x4 3500 Dual Rear Wheel - 196,### miles

Vortec 454

New Venture 4500 5-speed manual transmission

Borg Warner (something) floor shift transfer case (with this tcase and transmission combo the truck has 3 PTO provisions)

FACTORY 4.56 gears w/G80 in the rear

Chrome wheels that have been painted black

Dark Hunt Club Red Metallic exterior paint

Light smoke gray cloth interior, 60/40 split bench with lumbar on both sides.

One atrocious analog radio that wasn't even connected, the pigtail had been hacked off.

Pictures from the day we looked at it and brought it home. Year should be 2011 from the camera, forgot that it had been reset.