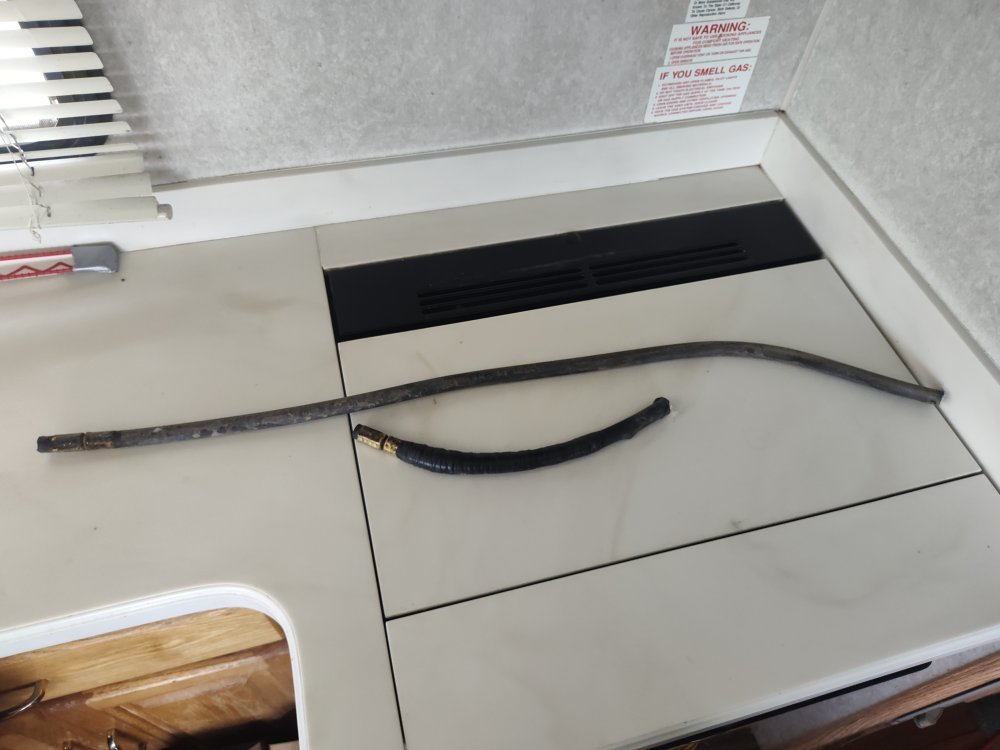

back in business....

guess what, my bleeding off fuel pressure is gone too, who would have guessed that?

i should not have pushed the bleeding fuel pressure towards dead check valve /pressure regulator like forums kept telling me...

guess what, my bleeding off fuel pressure is gone too, who would have guessed that?

i should not have pushed the bleeding fuel pressure towards dead check valve /pressure regulator like forums kept telling me...