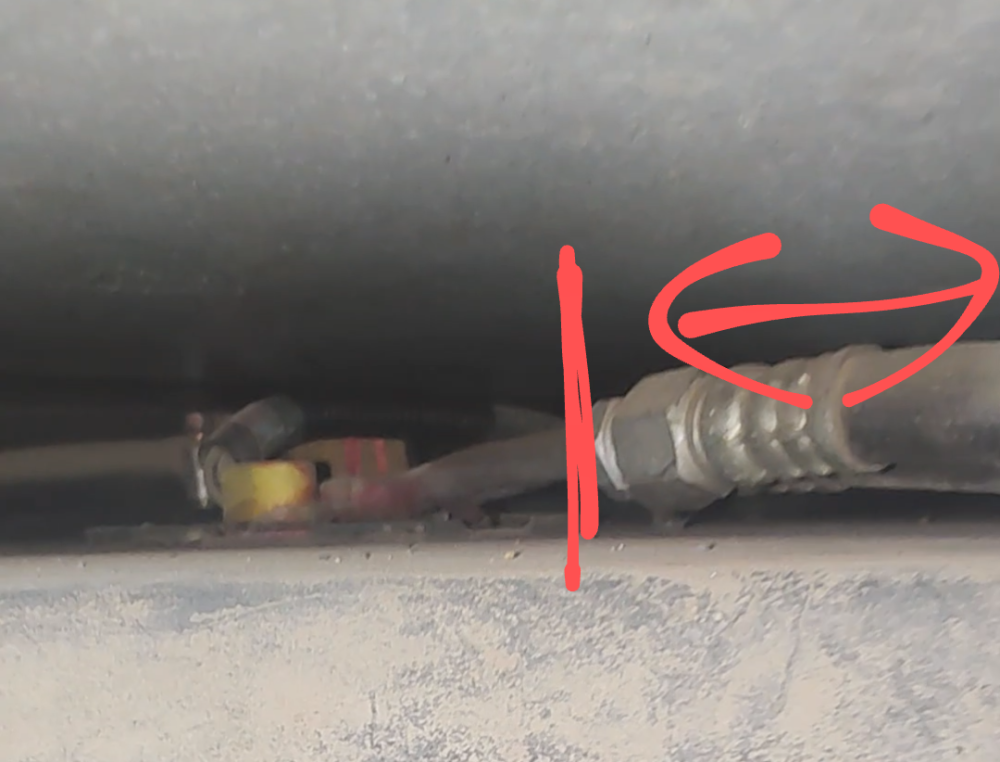

I'm close to my "out of season" next 10 month parking spot, ive got a car to get around. so im fairly mobil. just need to get someone to make me those hoses.

in the meantime i run my genset to run down the tank. no way im lifting 400 pounds of fuel out of there.

in the meantime i run my genset to run down the tank. no way im lifting 400 pounds of fuel out of there.