As a test, I connected my shut off selenoid to some jumper wires and power. It behaved as expected, worked fine. Can it still be receiving a bad signal that is making my engine shut off during idling at a cold starts? Here is my question: what is another way to test my selenoid is function properly on the go? Would it be unsafe to simply disconnect its electrical connection while it’s idling to see if the problem goes away? Or might that cause more problems and codes? Thanks

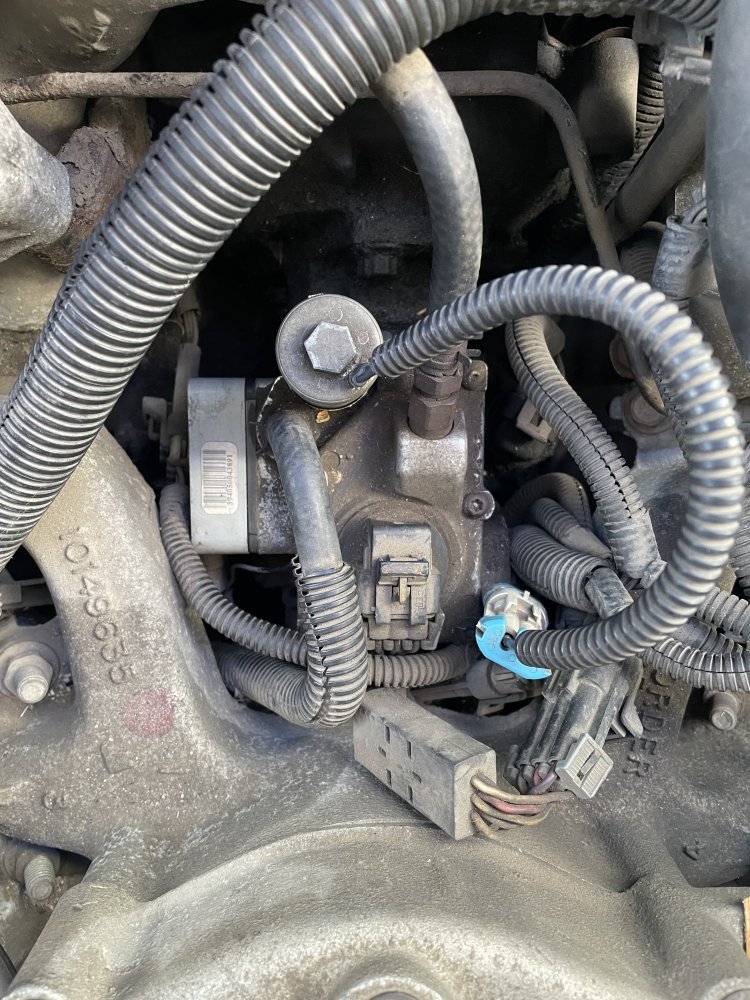

(I always try to include some visual, hope it helps)

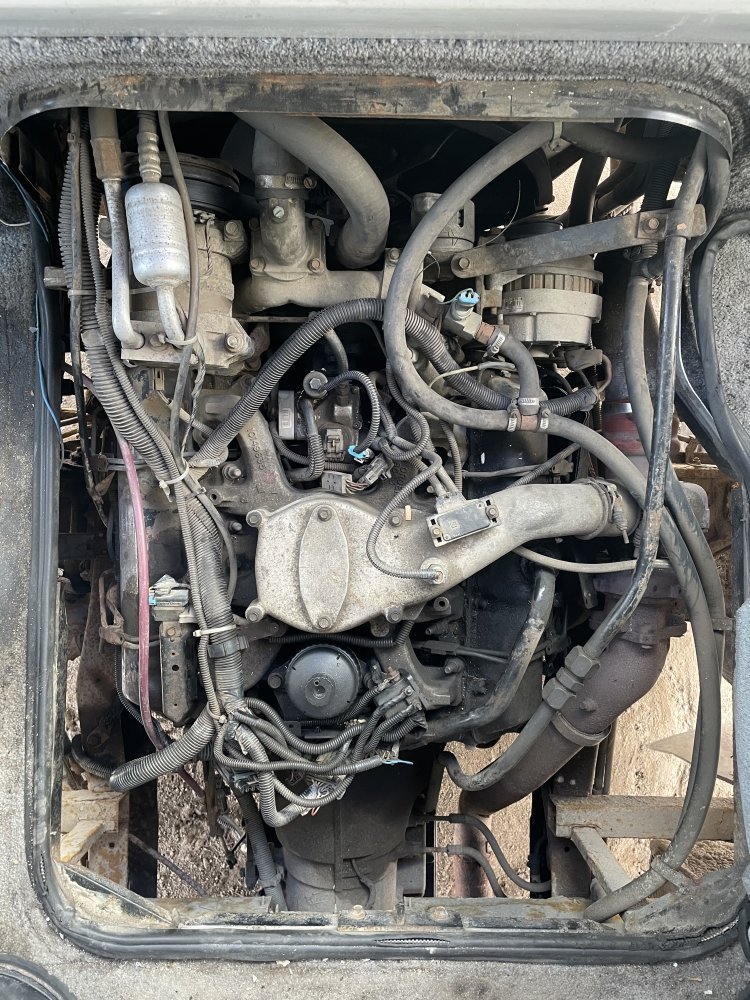

(I always try to include some visual, hope it helps)