Hi again fellows! I'm the one that has the 1996 Safari Trek motorhome with the 6.5TD with

the pop at turbo and tail pipe and the problem was the glow plugs and injectors that I changed....and it solved that problem. I have put about 250 miles on the motorhome and it runs great.

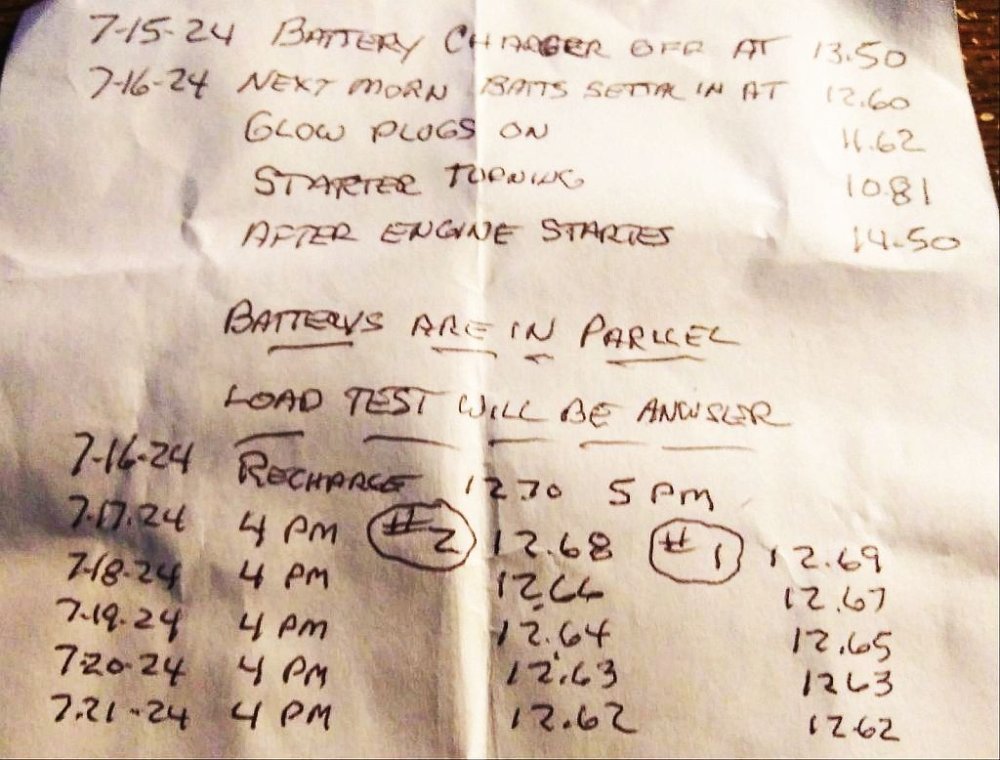

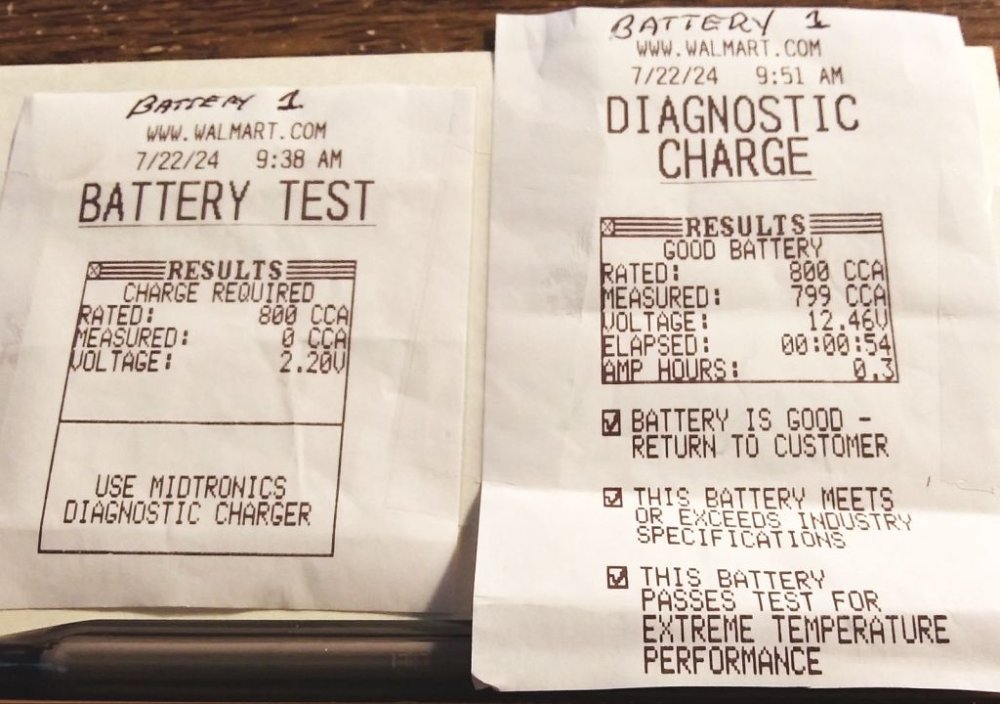

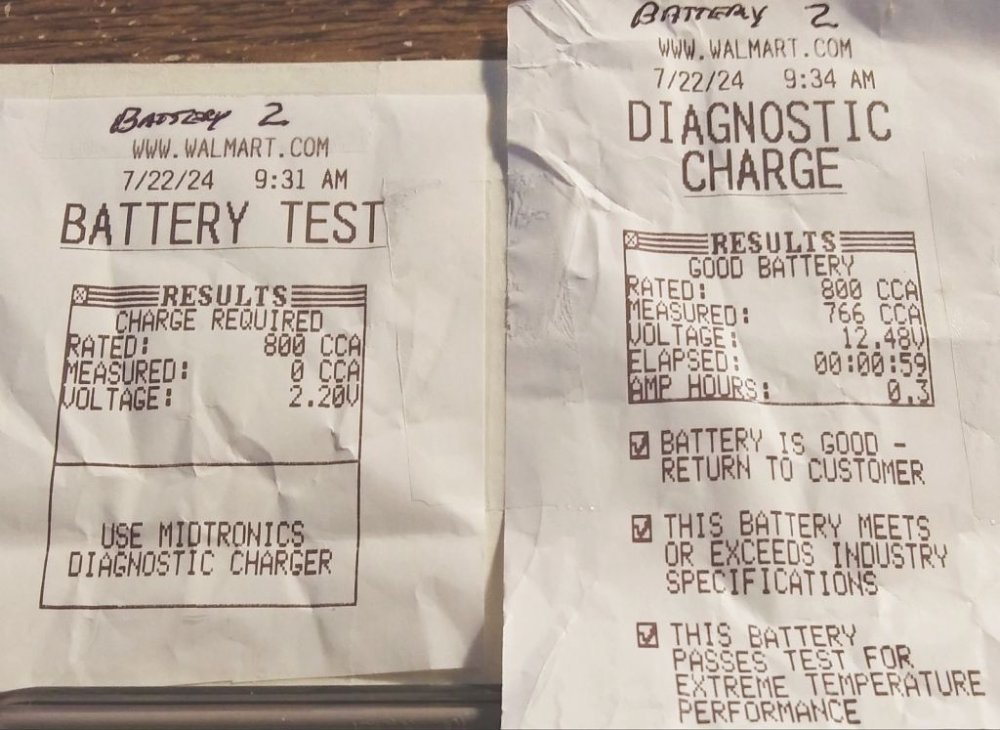

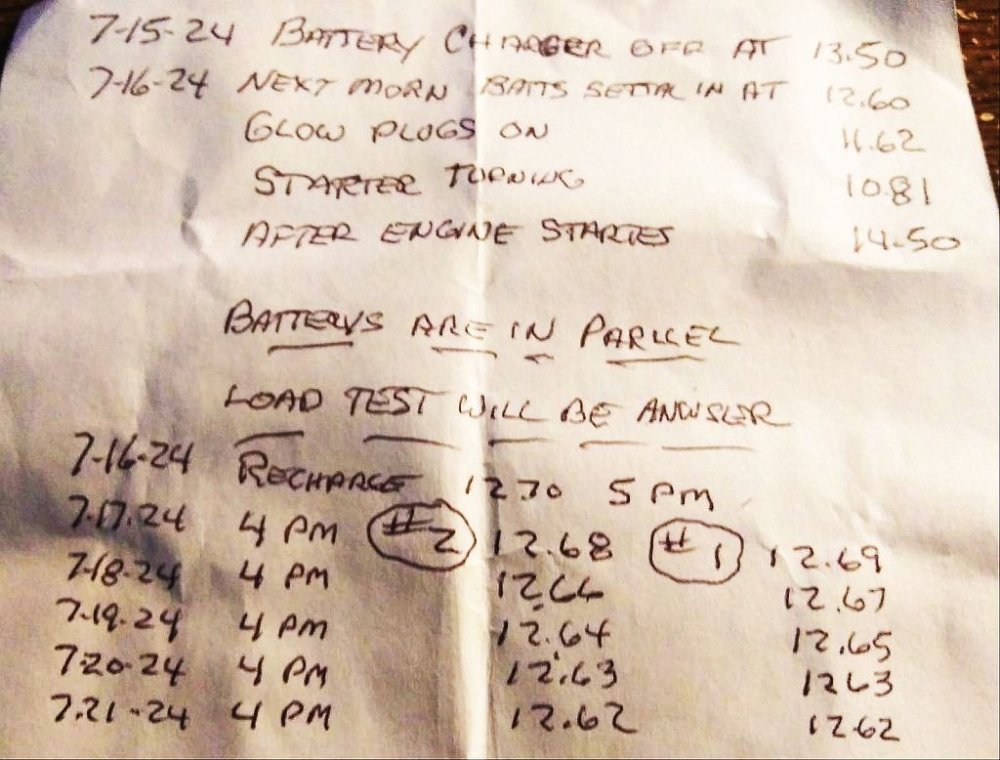

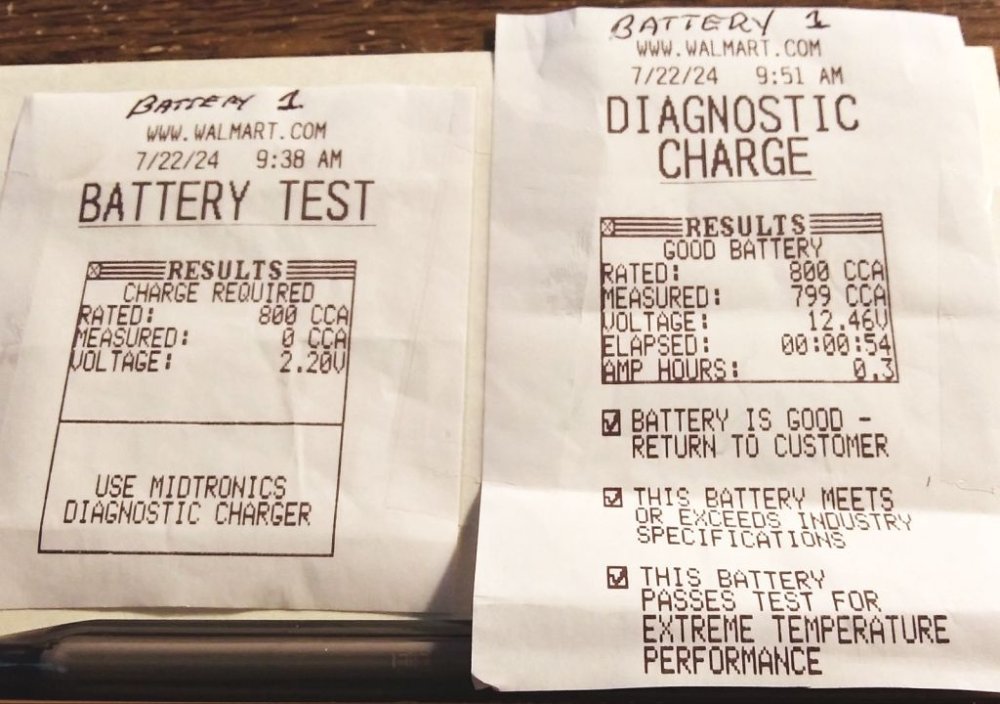

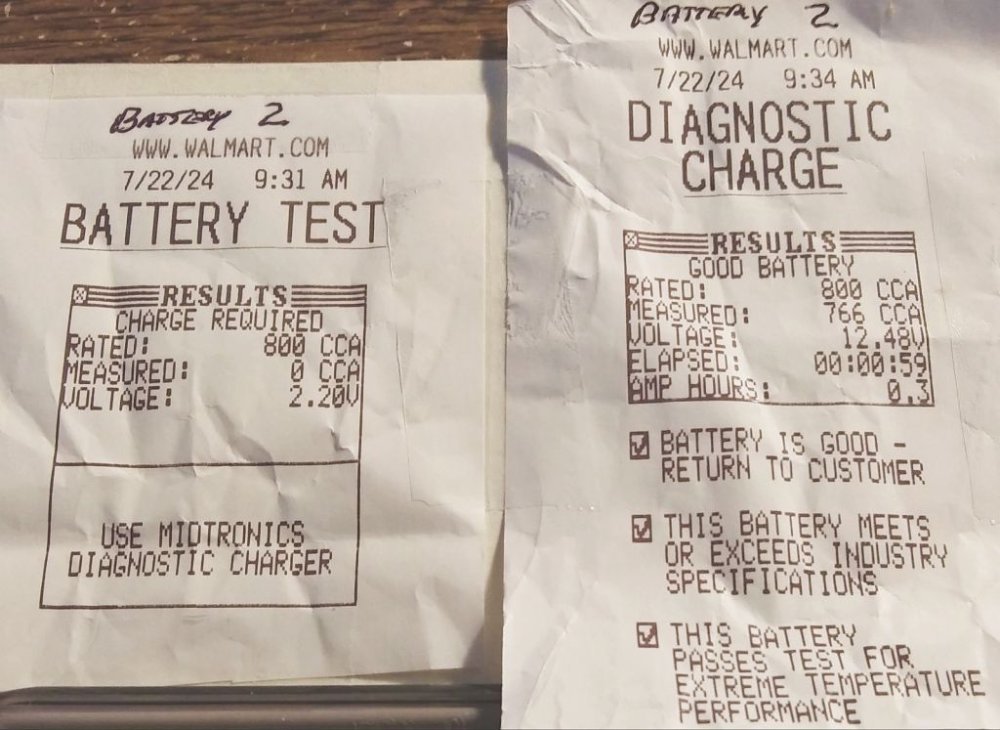

Now I have a starting problem. The batteries stay at 12.80 V with my tender. What is happening after the glow plug light goes out ... and I go to start the engine right away....and it wants to start but it fails to start. Then I wait about 4 seconds and try to start it again.... and it finally starts. (Starter turns over just fine).

After the engine starts- it goes right to idle. The engine does not race up and fall back to idle...like a normal start up?

**************************************************

I have found this that tells about bleeding the system:

"How To Bleed Injectors On A 6.5 Turbo Diesel?

6.5TD Post Addict.As far a bleeding goes all you need to do is crank the engine over for cycles of 15 seconds followed by a starter cool down period of 1 minute,it will self bleed. I like to crack 1 injector line loose while bleeding the high pressure side,it seems to speed things up a bit but is not mandatory."

***************************************************

I have bled the system any way and found no air and no leaks. And it runs just fine without any problems.

What do you think is going on here with the start up?

the pop at turbo and tail pipe and the problem was the glow plugs and injectors that I changed....and it solved that problem. I have put about 250 miles on the motorhome and it runs great.

Now I have a starting problem. The batteries stay at 12.80 V with my tender. What is happening after the glow plug light goes out ... and I go to start the engine right away....and it wants to start but it fails to start. Then I wait about 4 seconds and try to start it again.... and it finally starts. (Starter turns over just fine).

After the engine starts- it goes right to idle. The engine does not race up and fall back to idle...like a normal start up?

**************************************************

I have found this that tells about bleeding the system:

"How To Bleed Injectors On A 6.5 Turbo Diesel?

6.5TD Post Addict.As far a bleeding goes all you need to do is crank the engine over for cycles of 15 seconds followed by a starter cool down period of 1 minute,it will self bleed. I like to crack 1 injector line loose while bleeding the high pressure side,it seems to speed things up a bit but is not mandatory."

***************************************************

I have bled the system any way and found no air and no leaks. And it runs just fine without any problems.

What do you think is going on here with the start up?