Big T

Well-Known Member

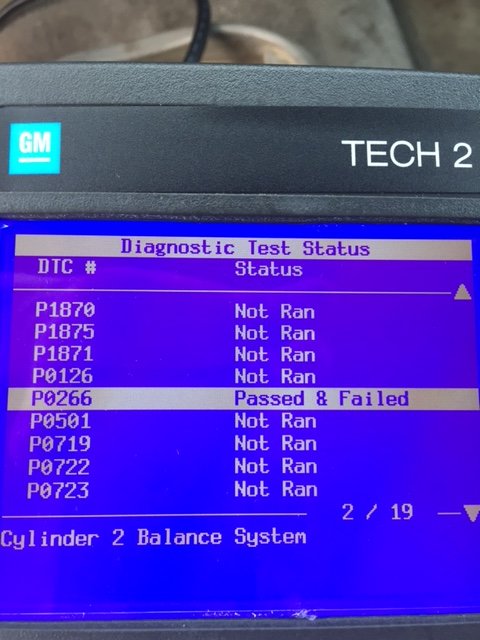

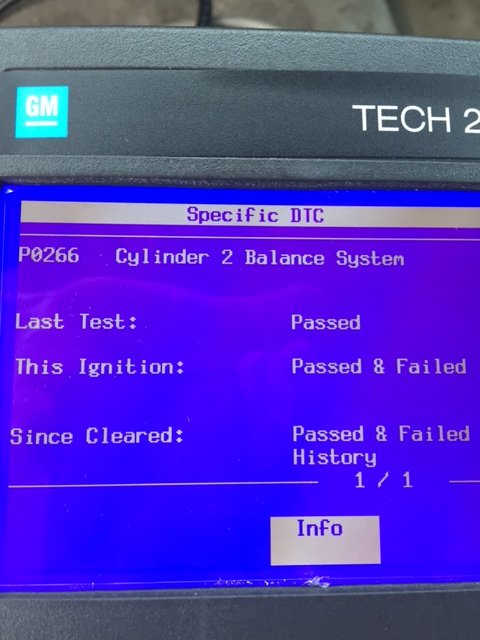

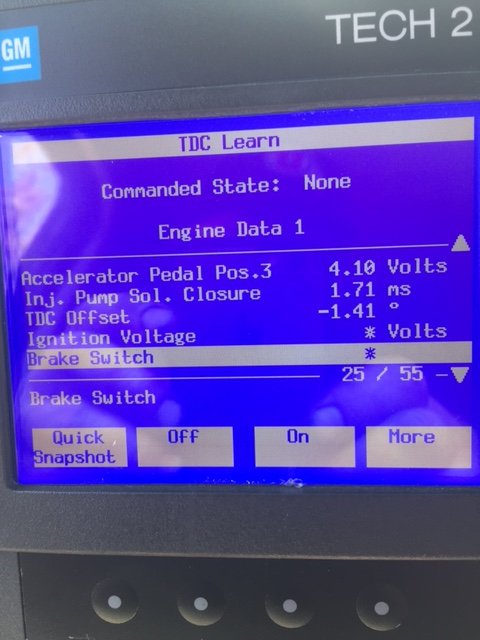

Plugged it in and lost as to how to use it.

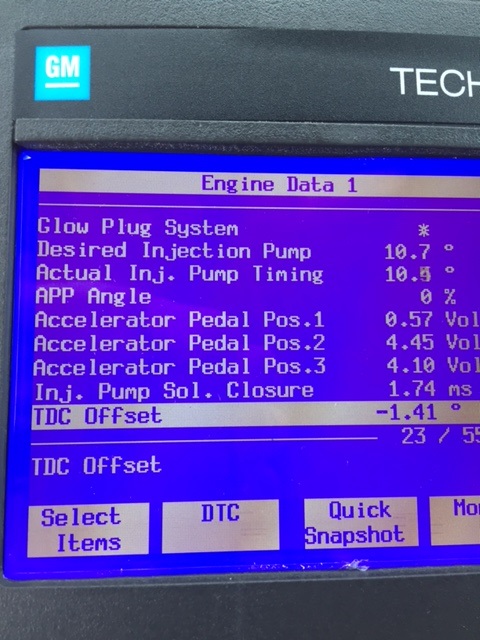

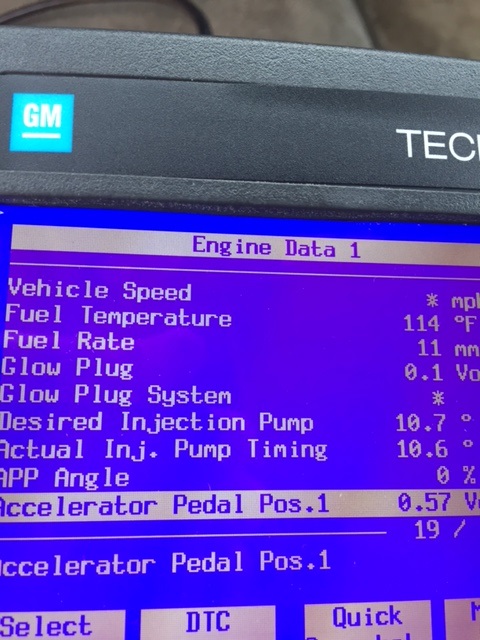

1. Would like to set TDCO. (Priority 1 today).

2. Would like to pull ABS Codes. (Priority 2 down the road)

3. Would like to pull Transfer Case Codes. (Priority 3 down the road).

1. Would like to set TDCO. (Priority 1 today).

2. Would like to pull ABS Codes. (Priority 2 down the road)

3. Would like to pull Transfer Case Codes. (Priority 3 down the road).