chevyCowboy

I might be crazy but i ain't dumb

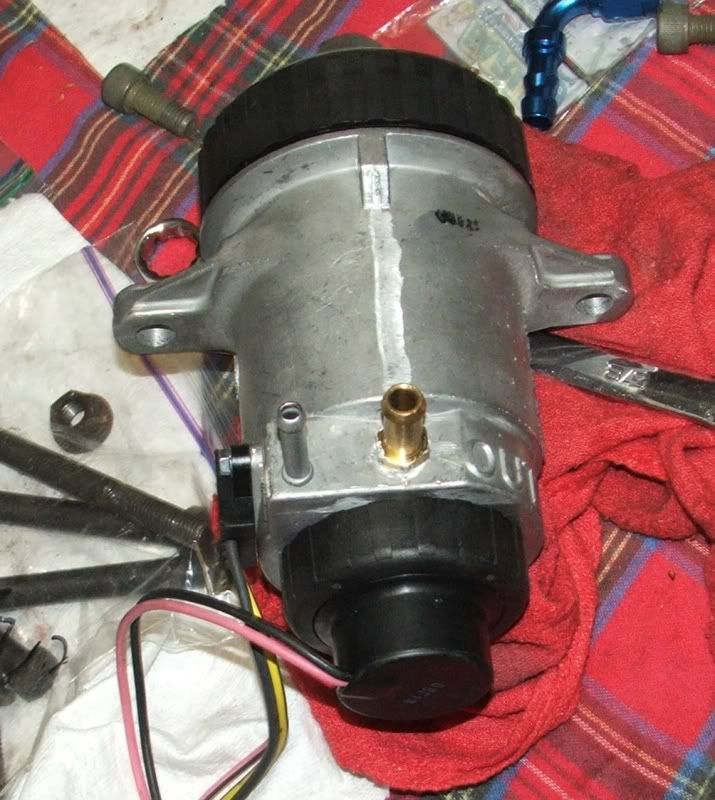

getting close to putting the engine back into my 93. every things just about done so i got the FTB kit out that i orderd from Walking J, and it turns out that it doesnt work on the db2 :mad2:, no big deal ill just use it on my dually when i get it running, but the question is?

is there a way to make a FTB setup on a DB2?

im hopeing so other wise iv got to go pull the FFM off the dually since i had allready drilled and taped it for the larger fitting

is there a way to make a FTB setup on a DB2?

im hopeing so other wise iv got to go pull the FFM off the dually since i had allready drilled and taped it for the larger fitting