hi!

i have stummbled upon a problem with my 6.5TD 1999 and maby some of you guys can point me in the right Direction,

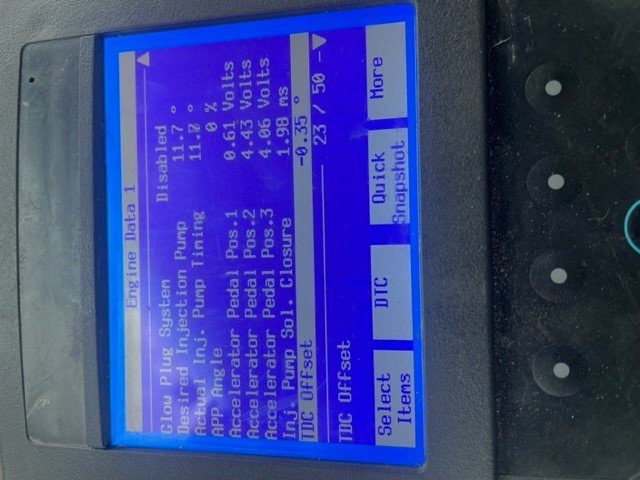

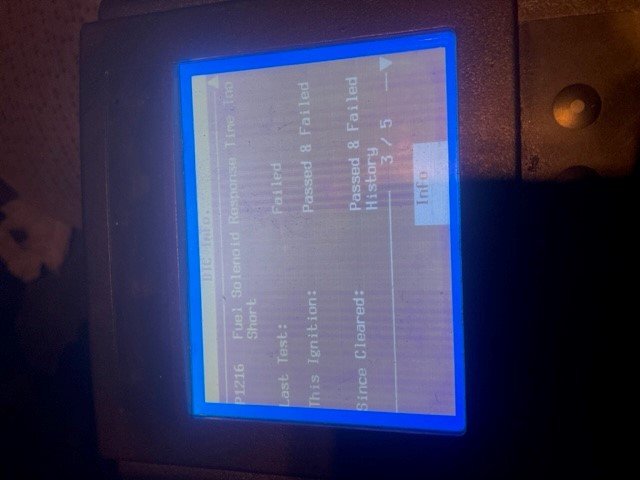

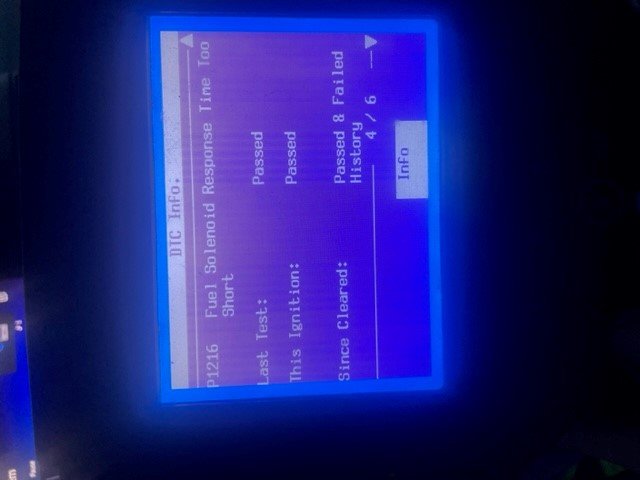

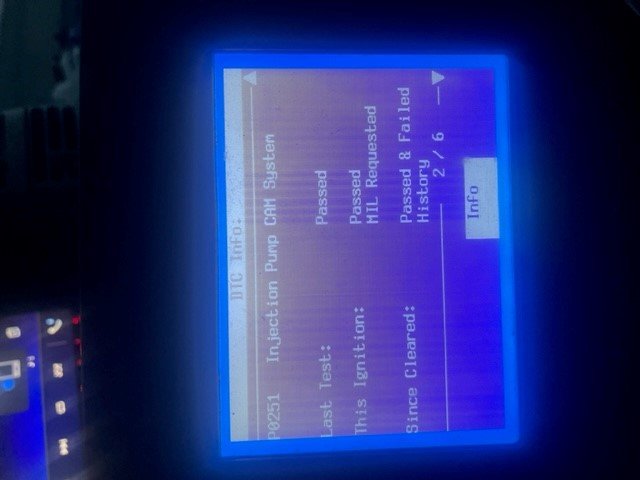

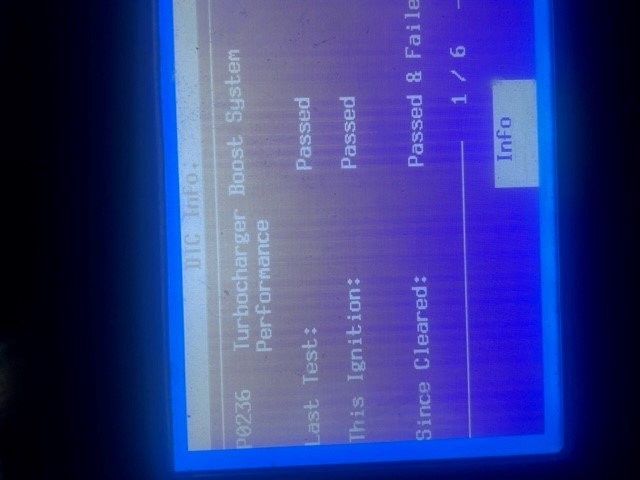

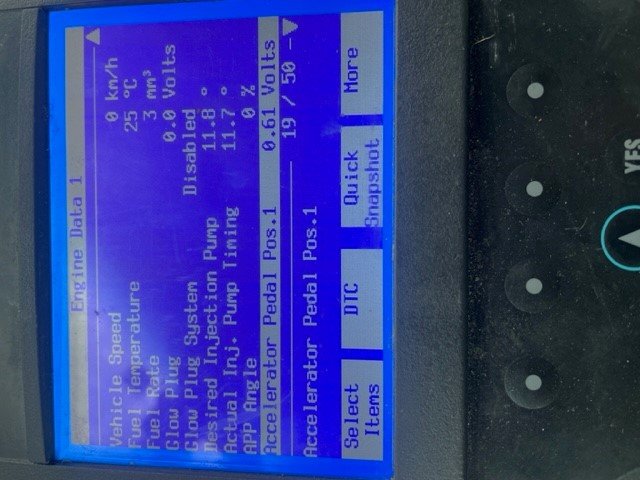

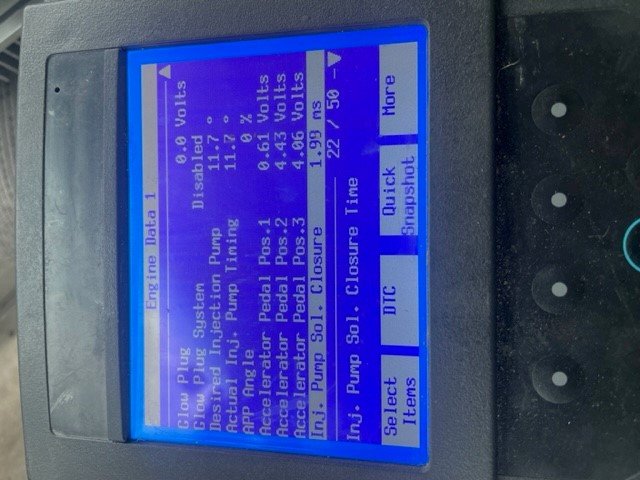

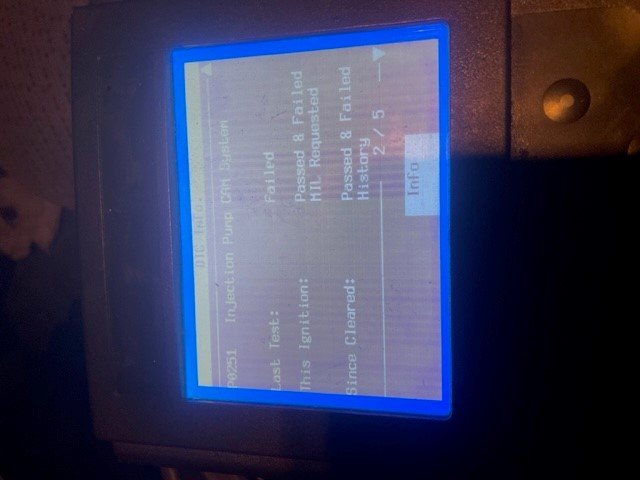

i can start the car up as normal, runnes fine unntil it getts warm, then it sounds like it is missfireing (it cuttes of the engine in a secund befoure it runnes fine again it has even stallled out on me, all dead pedal,) and a lotts of cranking and then start, i have a tech2 and did have a look on the fulerate is rapidly bouncing when the car starts to act up,

maby its something with the pump timing?

I have changed the fulefilter,PMD New fresh Diesel and still running bad :/

i have stummbled upon a problem with my 6.5TD 1999 and maby some of you guys can point me in the right Direction,

i can start the car up as normal, runnes fine unntil it getts warm, then it sounds like it is missfireing (it cuttes of the engine in a secund befoure it runnes fine again it has even stallled out on me, all dead pedal,) and a lotts of cranking and then start, i have a tech2 and did have a look on the fulerate is rapidly bouncing when the car starts to act up,

maby its something with the pump timing?

I have changed the fulefilter,PMD New fresh Diesel and still running bad :/

Attachments

-

feilmelding 1.jpg52.9 KB · Views: 5

feilmelding 1.jpg52.9 KB · Views: 5 -

feilmelding 9.jpg43.1 KB · Views: 4

feilmelding 9.jpg43.1 KB · Views: 4 -

feilmelding 8.jpg37.5 KB · Views: 4

feilmelding 8.jpg37.5 KB · Views: 4 -

feilmelding 7.jpg42.4 KB · Views: 4

feilmelding 7.jpg42.4 KB · Views: 4 -

feilmelding 6.jpg39.6 KB · Views: 3

feilmelding 6.jpg39.6 KB · Views: 3 -

feilmelding 5.jpg41.7 KB · Views: 3

feilmelding 5.jpg41.7 KB · Views: 3 -

feilmelding 4.jpg53.2 KB · Views: 3

feilmelding 4.jpg53.2 KB · Views: 3 -

feilmelding 3.jpg52.4 KB · Views: 3

feilmelding 3.jpg52.4 KB · Views: 3 -

feilmelding 2.jpg54.7 KB · Views: 3

feilmelding 2.jpg54.7 KB · Views: 3 -

feilmelding 10.jpg42 KB · Views: 5

feilmelding 10.jpg42 KB · Views: 5